Micro/nano potassium yttrium tungstate near-spherical particles and preparation method thereof

A technology of yttrium potassium tungstate and spherical particles, which is applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve problems such as limited scope of application, expensive raw materials, difficulty in powder collection, etc., and achieve broad application prospects. Uniform particle size distribution and improved luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

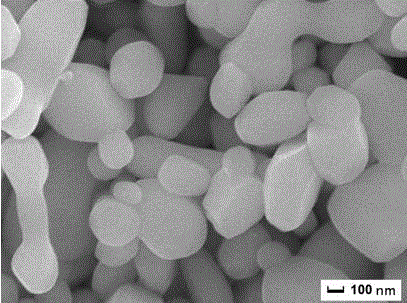

[0023] Weigh a certain amount of hydrated K 2 WO 4 , Y 2 o 3 Dissolve in deionized water and dilute nitric acid respectively, and prepare WO 4 2- Solution and Y 3+ Ionic solution; adjust the pH values of the two solutions, then mix and stir, then adjust the pH value of the mixed solution to 5, and then add acetylacetone with a volume fraction of 20% of the mixed solution to the mixed solution and ultrasonically vibrate for half an hour to obtain a precursor solution . Put the prepared precursor solution in a hydrothermal kettle at 180°C for 20 hours, filter the solution after hydrothermal insulation, clean the filter, put it into a crucible, transfer it to a high-temperature furnace and heat it at 800°C for 8 hours to obtain Micronano potassium yttrium tungstate particles. Depend on figure 1 As shown, the particle size is between 0.100 and 1 μm, and its powder diffraction pattern is shown in Figure 5 Shown in Example 1.

Embodiment 2

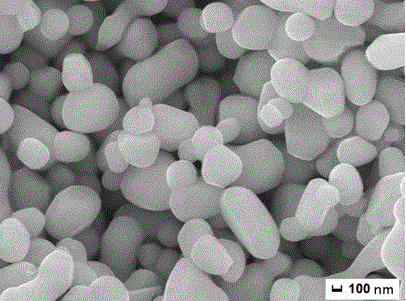

[0025] Weigh a certain amount of hydrated K 2 WO 4 , Y(NO 3 ) 3 Dissolve in deionized water and dilute nitric acid respectively, and prepare WO 4 2- Solution and Y 3+ Ionic solution; adjust the pH values of the two solutions, then mix and stir, then adjust the pH value of the mixed solution to 6, and then add acetylacetone with a volume fraction of 20% of the mixed solution to the mixed solution and ultrasonically vibrate for half an hour to obtain a precursor solution . Put the prepared precursor solution in a hydrothermal kettle at 180°C for 20 hours, filter the solution after hydrothermal insulation, clean the filter, put it into a crucible, transfer it to a high-temperature furnace and heat it at 800°C for 8 hours to obtain Micronano potassium yttrium tungstate particles. Depend on figure 2 As shown, the particle size is between 0.3 and 1 μm, and its powder diffraction pattern is shown in Figure 5 Shown in Example 2.

Embodiment 3

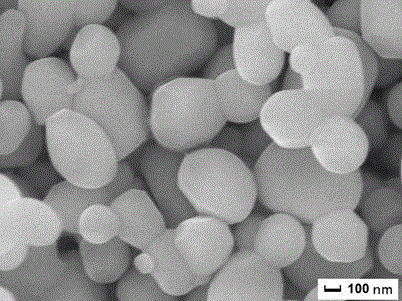

[0027] Weigh a certain amount of hydrated (NH 4 ) 2 WO 4 , Y 2 o 3 Dissolve in deionized water and dilute nitric acid respectively, and prepare WO 4 2- Solution and Y 3+ Ionic solution; adjust the pH values of the two solutions, then mix and stir, then adjust the pH value of the mixed solution to 7, and then add acetylacetone with a volume fraction of 15% of the mixed solution to the mixed solution and ultrasonically vibrate for half an hour to obtain a precursor solution . Put the prepared precursor solution in a hydrothermal kettle at 180°C for 20 hours, filter the solution after hydrothermal insulation, clean the filter, put it into a crucible, transfer it to a high-temperature furnace and heat it at 800°C for 4 hours to obtain Micronano yttrium potassium tungstate particles. Depend on image 3 As shown, the particle size is between 0.1 and 0.7 μm, and its powder diffraction pattern is shown in Figure 5 Shown in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com