A recovery and adsorption method for tungstate in scheelite mineral processing wastewater

A technology of mineral processing wastewater and tungstate, which is applied in mining wastewater treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low recovery rate of tungstate and slow recovery rate, so as to prevent secondary pollution and realize Recycling, the effect of enhancing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific implementation mode 1: This implementation mode is a method for recovering and adsorbing tungstate in scheelite mineral processing wastewater, and the specific steps are as follows:

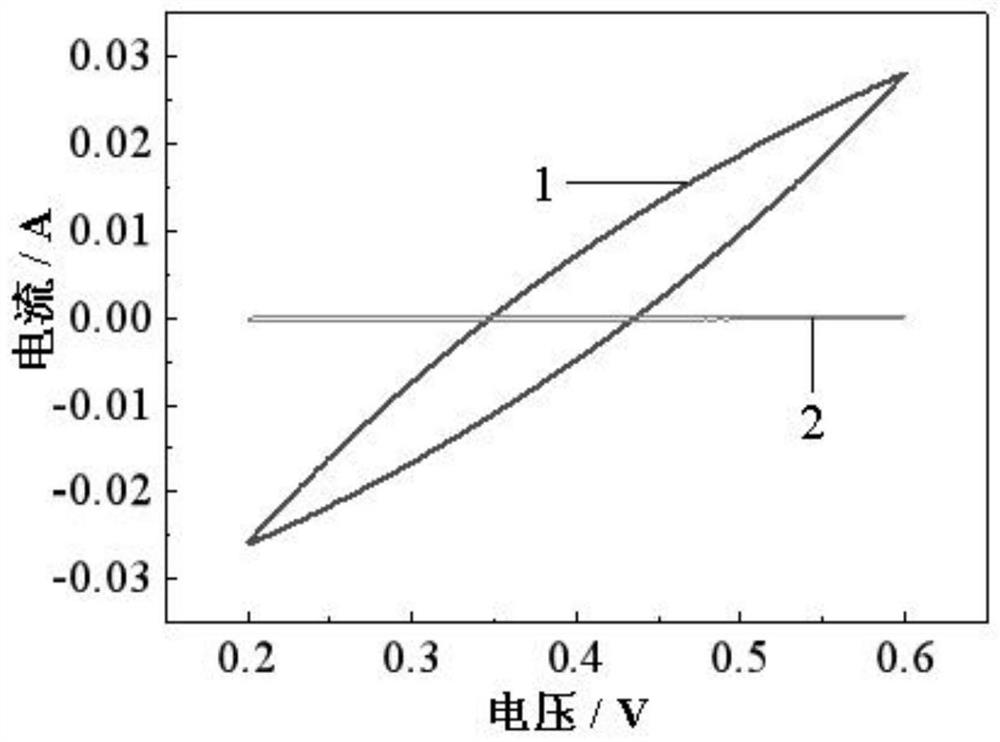

[0026] The three-electrode system composed of polyaniline / carbon cloth composite electrode material, Ag / AgCl electrode and platinum electrode is connected to the electrochemical workstation, the polyaniline / carbon cloth composite electrode material is used as the working electrode, the Ag / AgCl electrode is used as the reference electrode, and the platinum electrode is The electrode is the counter electrode, and the scheelite ore dressing wastewater to be treated is used as the electrolyte, and the electric adsorption is carried out under the condition of a voltage of 0.5V-1.2V for 2h-6h.

specific Embodiment approach 2

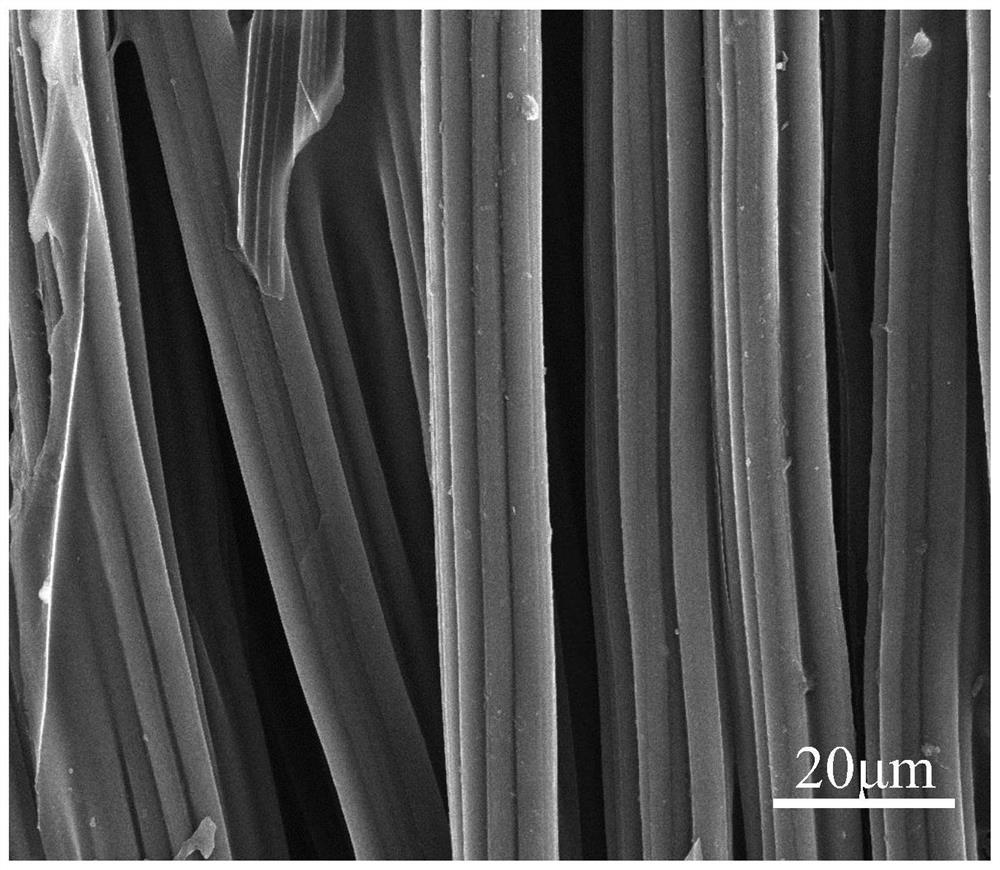

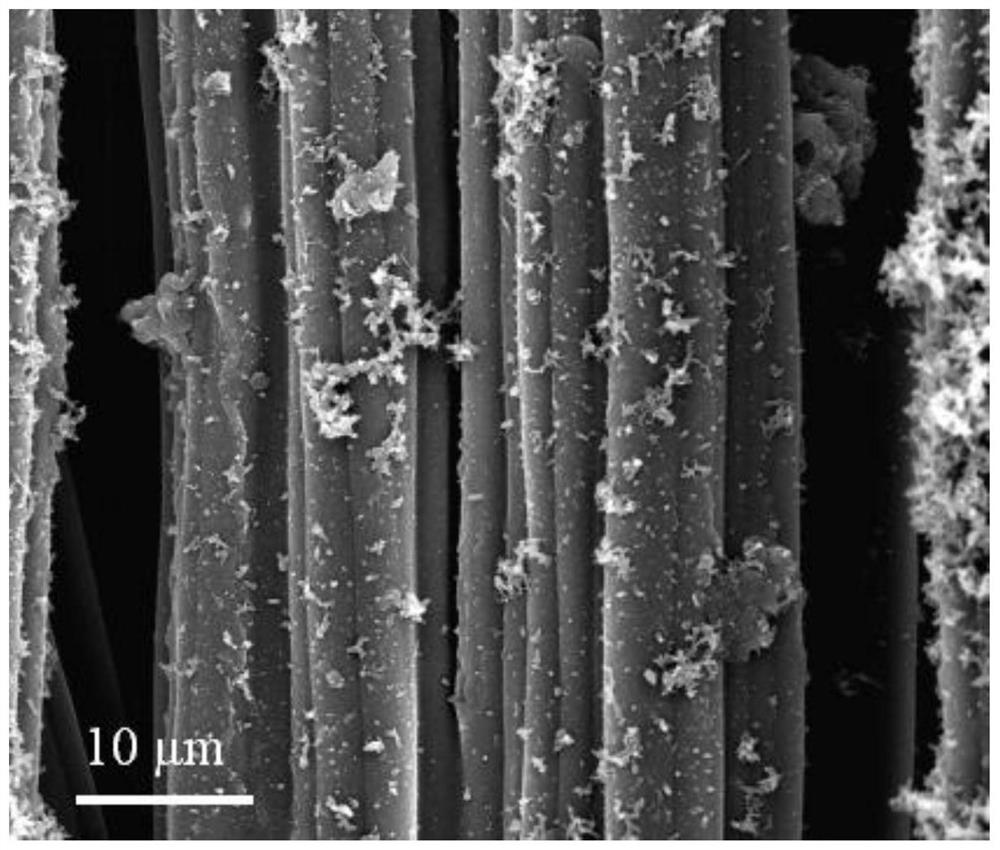

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the preparation method of the polyaniline / carbon cloth composite electrode material is as follows:

[0028] 1. Add the carbon cloth and aniline to the HCl aqueous solution, completely immerse the carbon cloth in the mixture, and then ultrasonically 30-40 minutes to disperse the aniline to the surface of the carbon cloth;

[0029] The concentration of the aqueous HCl solution is 0.1mol / L to 0.12mol / L;

[0030] The volume ratio of the aniline to the HCl aqueous solution is 1:(30~35);

[0031] 2. Add ammonium persulfate into HCl aqueous solution and dissolve it by ultrasonic;

[0032] The concentration of the aqueous HCl solution is 0.1mol / L to 0.12mol / L;

[0033] The quality of described ammonium persulfate and the volume ratio of HCl aqueous solution are (0.5g~0.6g): 15mL;

[0034] 3. Add the sonicated solution in step 2 dropwise to the sonicated solution in step 1, then pl...

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the electrosorption is performed for 2 hours to 3 hours under the condition of a voltage of 1V. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com