Synthesis method of electrode material cobalt tungstate for supercapacitor

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, chemical instruments and methods, cobalt compounds, etc., can solve the problems of complex preparation process, long reaction time, cumbersome process, etc., and achieve simple synthesis method, low cost of raw materials, The effect of improving capacitor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0036] In the synthetic method of the electrode material cobalt tungstate of this example, at first cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and deionized water are mixed and dissolved according to the mass ratio of 0.002:1 to obtain solution A, and then the morphology regulator ammonium fluoride, sodium tungstate (Na 2 WO 4 4H 2 O) and deionized water were mixed and dissolved according to the mass ratio of 0.001:0.002:1 to obtain solution B. Then solution A and solution B were mixed in equal volumes and subjected to precipitation reaction. The reaction temperature was 25°C and the reaction time was 4 hours. After the reaction was completed, it was cooled and washed three times by deionized water and ethanol, respectively, and finally in a vacuum of Under the condition of 0.8KPa and temperature of 60°C, carry out vacuum drying for 10h to obtain cobalt tungstate.

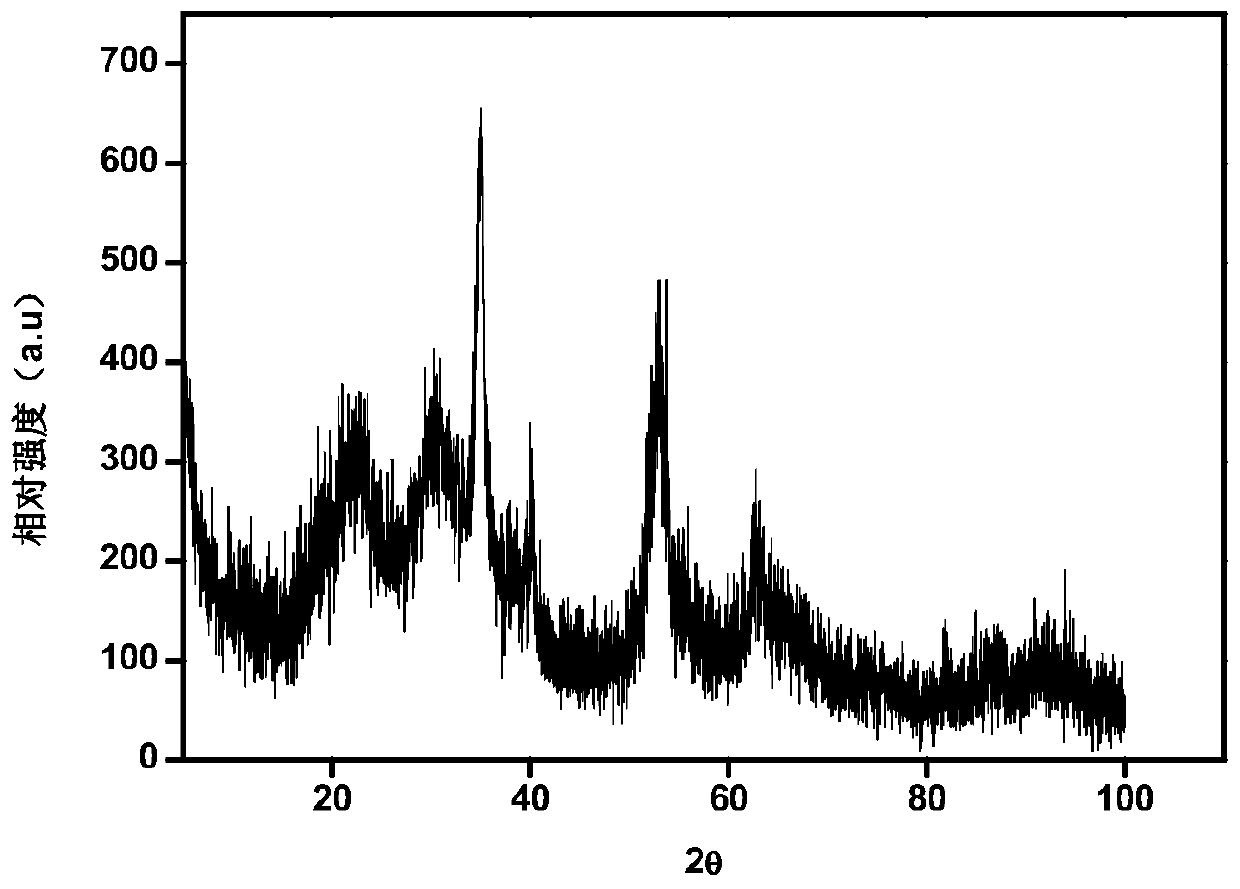

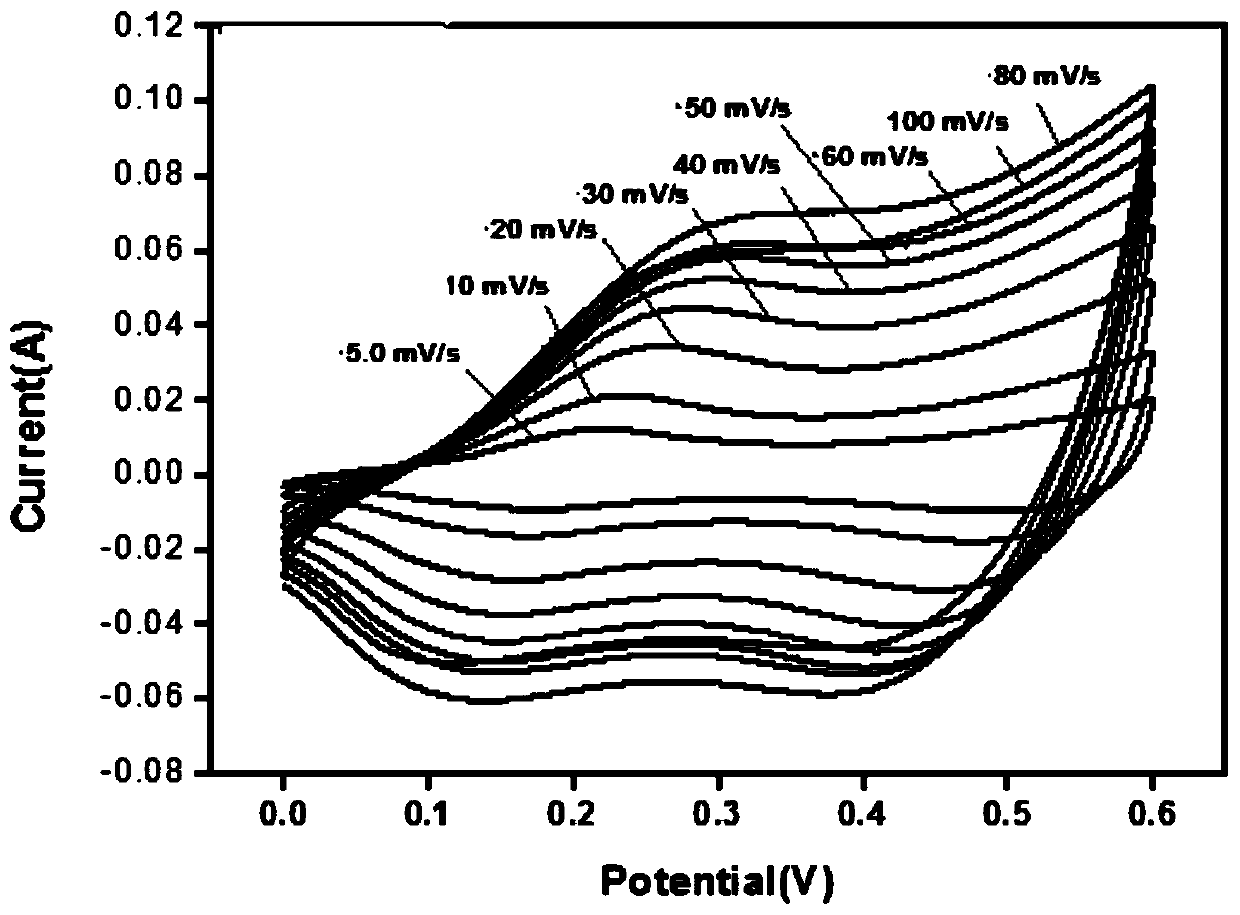

[0037] The cobalt tungstate synthesized in this preparation example, after testing its XRD pattern is as f...

preparation example 2

[0041] In the synthetic method of the electrode material cobalt tungstate of this example, at first cobalt nitrate (Co(NO 3 ) 2 ) and deionized water are mixed and dissolved according to the mass ratio of 0.003:1 to obtain solution A, and then the morphology regulator sodium lauryl sulfate, calcium tungstate (CaWO 4 ) and deionized water were mixed and dissolved according to the mass ratio of 0.001:0.003:1 to obtain solution B. Then solution A and solution B were mixed in equal volumes to carry out precipitation reaction. The reaction temperature was 40°C and the reaction time was 6 hours. After the reaction was completed, it was cooled and washed three times by centrifugation with deionized water and ethanol. Under the condition of 0.8KPa and temperature of 60°C, carry out vacuum drying for 10h to obtain cobalt tungstate.

[0042] The cobalt tungstate electrode material synthesized in this example adopts the same electrochemical test, and its specific capacitance value reac...

preparation example 3

[0044] In the synthetic method of the cobalt tungstate of this example, at first cobalt bromide (CoBr 2 ) and deionized water are mixed and dissolved at a ratio of 0.004:1 to obtain solution A, and then the morphology regulator hexadecyltrimethylammonium bromide, cadmium tungstate (CdWO 4 ) and deionized water were mixed and dissolved according to the mass ratio of 0.002:0.004:1 to obtain solution B. Then, solution A and solution B were mixed in equal volumes and subjected to precipitation reaction. The reaction temperature was 90° C., and the reaction time was 8 hours. After the reaction was completed, it was cooled and washed three times by deionized water and ethanol, respectively. Under the condition of 0.8KPa and temperature of 60°C, carry out vacuum drying for 10h to obtain cobalt tungstate.

[0045] The cobalt tungstate electrode material synthesized in this example adopts the same electrochemical test, and its specific capacitance value reaches 178.85F / g at a current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com