Method for synthesizing fluorescent powder of yttrium aluminum garnet

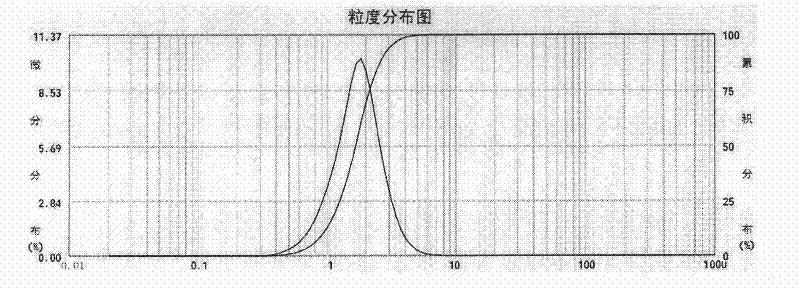

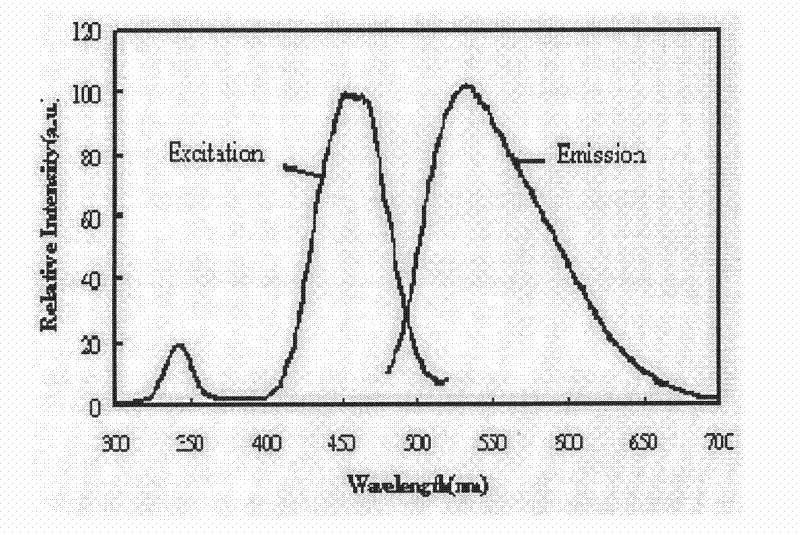

A technology of yttrium aluminum garnet and synthesis method, which is applied in the field of phosphor powder preparation, can solve problems such as difficulty in obtaining uniformly dispersed particles, small powder, and hard agglomeration of phosphor particles, and achieve easy washing and filtering, easy control, and particle evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Select the raw material, the raw material is selected from Y 2 o 3 , Ce(NO 3 ) 3 , Al(NO 3 ) 3 , its composition and content according to Y 3-x Al 5 o 12 : Ce 3+ x , where x = 0.06 mol / mol. First prepare the metal ion mixed solution; then prepare the composite precipitant, and then prepare the precursor by chemical co-precipitation method. The reaction process is carried out in the ultrasonic microwave synthesizer, the ultrasonic time is 5min, the microwave power is 100w, and the concentration of the reactant is controlled. 1mol / L, precipitant NH 4 HCO 3 The concentration of the solution is 1mol / L, the speed of adding the mixed solution of yttrium aluminum cerium metal salt ion is 2L / min, carry out strong magnetic stirring, after the addition is completed, the ammonia solution is slowly dropped into the mixed solution, the pH is controlled at 8, all drops Continue to stir for 0.5h after the addition, and age for 8h; after the aging, take the precursor out an...

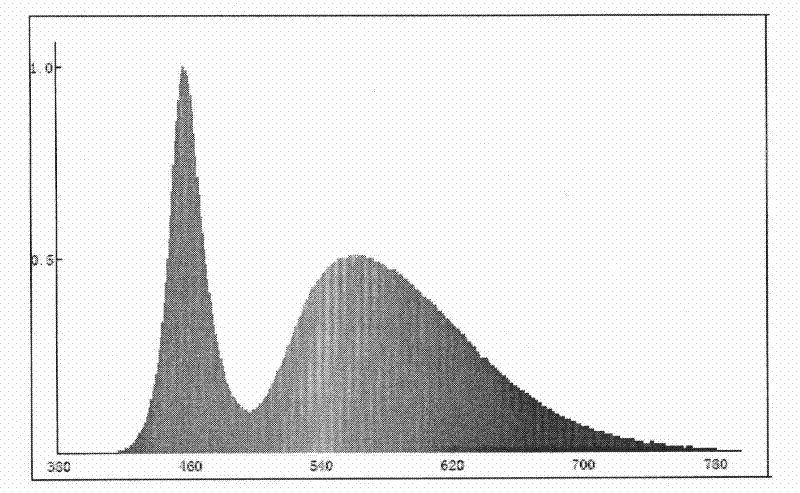

Embodiment 2

[0038] Select the raw material, the raw material is selected from Y 2 o 3 , Gd 2 o 3 , Ce(HNO 3 ) 3 , Pr 2 o 3 , Al(HNO 3 ) 3 , Ga 2 o 3 , ScO 2 , its composition according to (Y 1-x Gd x ) 3 (Al 1-y-z Ga y sc z ) 5 o 12 : Ce m 3+ PR n 3+ , where x=0.1 mol / mol, y=0.1 mol / mol, z=0.2 mol / mol, m=0.06 mol / mol, n=0.1 mol / mol. First prepare the metal ion mixed solution; then prepare the composite precipitant, and then prepare the precursor by chemical co-precipitation method. The reaction process is carried out in the ultrasonic microwave synthesizer, the ultrasonic time is 5min, the microwave power is 100w, and the concentration of the reactant is controlled. is 1mol / L, the reaction temperature and aging temperature are both at room temperature, and the precipitant NH 4 HCO 3 The concentration of the metal salt ion solution is 1mol / L, the speed of adding the metal salt ion solution is 2L / min, and strong magnetic stirring is carried out. After the addition i...

Embodiment 3

[0041] Select the raw material, the raw material is selected from Y 2 o 3 , Ce(NO 3 ) 3 , Al(NO 3 ) 3 , Pr 2 o 3 , its composition and content according to Y 3-x-y Al 5 o 12 : Ce 3+ x , where x = 0.06 mol / mol. First prepare the metal ion mixed solution; then prepare the composite precipitant, and then prepare the precursor by chemical co-precipitation method. The reaction process is carried out in the ultrasonic microwave synthesizer, the ultrasonic time is 5min, the microwave power is 100w, and the concentration of the reactant is controlled. is 1mol / L, the reaction temperature and aging temperature are both at room temperature, and the precipitant NH 4 HCO 3 The concentration of the metal salt ion solution is 1mol / L, the speed of adding the metal salt ion solution is 2L / min, and strong magnetic stirring is carried out. After the addition is completed, the ammonia solution is slowly dropped into the mixed solution, and the pH is controlled at 8. After the additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com