Process for preparing magnesium alloy and its composite material

A composite material and preparation technology, which is applied in the field of metal matrix composite material processing, can solve the problems of complex hot pressing equipment, large investment, and low benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

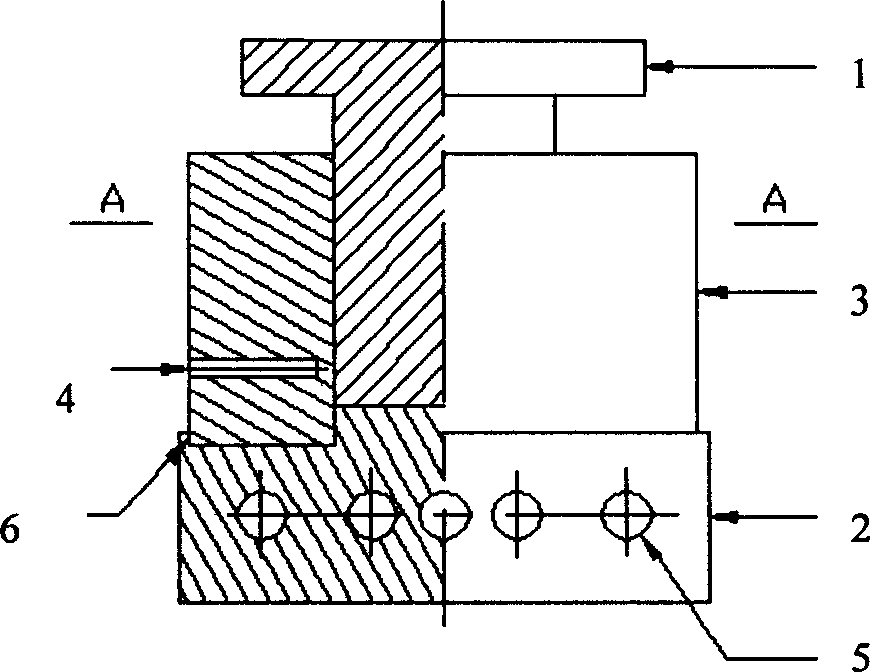

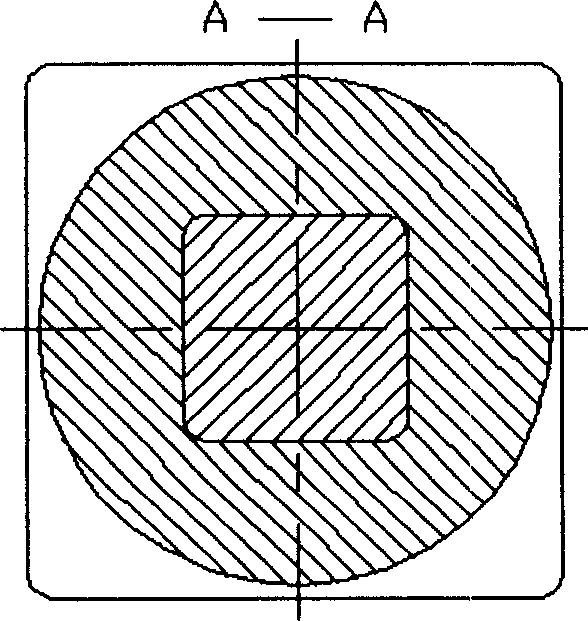

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of powdered Mg70-Al16-Cu3-Zn5-RE3-Mn2-Si1 alloy.

[0026] The magnesium alloy powder was ball milled for 5 hours under the protection of ethanol, the ball-to-material ratio was 20:1, and the rotational speed was 300 r / min. According to the theoretical density of the original magnesium alloy 2.0g / cm 3 , select 6.4g of magnesium alloy powder after ball milling, and the volume after pressing is 3.2cm 3 . Put the magnesium alloy powder into the hot pressing mold. During hot pressing, first raise the temperature to 200°C, keep it warm for half an hour, then raise the temperature to 300°C, keep it warm for 1 hour, and keep adjusting the pressure during the sintering process so that the density of the magnesium alloy is close to its theoretical density. The whole sintering process takes 2.5 hours. Hot rolling is carried out at 200°C, the heating rate is 20°C / min, the reduction rate is 50%, the feed rate is 0.3m / min, and the material yield strength σ ...

Embodiment 2

[0027] Example 2: Preparation of metal nickel-titanium long fiber reinforced magnesium alloy.

[0028] Mg80-Al10-Cu5-Zn2-RE1-Mn1.5-Si0.5 alloy was used as the base material, and it was ball milled for 8 hours under the protection of ethanol, the ball-to-material ratio was 15:1, and the rotational speed was 400r / min. Put the magnesium alloy powder and the nickel-titanium fiber into the hot pressing mold according to the sandwich structure. During hot pressing, first raise the temperature to 200°C, keep it warm for half an hour, then raise the temperature to 320°C, keep it warm for 2 hours, and gradually apply pressure during the sintering process, up to 375Mpa. The whole sintering process is 3.5 hours. The obtained composite material has uniform structure and good fiber / matrix combination. Hot rolling is carried out at 300°C, the heating rate is 15°C / min, the reduction rate is 30%, and the feed rate is 0.1m / min. Composite yield strength σ 0.2 Reach 260Mpa, tensile strength ...

Embodiment 3

[0029] Example 3: Preparation of a magnesium alloy reinforced with short aluminum-titanium fibers.

[0030] Mg70-Al16-Cu5-Zn5-RE2-Mn1-Si1 alloy was used as the matrix material, and ball milled for 8 hours under the protection of ethanol, the ball-to-material ratio was 15:1, and the rotational speed was 400r / min. The magnesium alloy powder and the aluminum-titanium fiber are uniformly mixed by ball milling, and the time of ball milling again is 15 minutes at a rotation speed of 300 r / min, under vacuum protection. Put the mixture into a hot-pressing mold for hot pressing, first raise the temperature to 200°C, keep it warm for half an hour, then raise the temperature to 450°C, keep it warm for 1 hour, and gradually apply pressure during the sintering process. The whole sintering process is 3 hours. The obtained composite material has uniform structure and good fiber / matrix combination. Hot rolling is carried out at 250°C, the heating rate is 15°C / min, the reduction rate is 40%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com