Method for electric-field-assisted low-temperature fast sintering of porous ceramics

A rapid sintering, porous ceramic technology, applied in ceramic products, applications, household appliances, etc., can solve the problems affecting the performance of porous ceramics, reduce porosity, etc., to improve particle activity and diffusion migration rate, reduce sintering time, speed up The effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

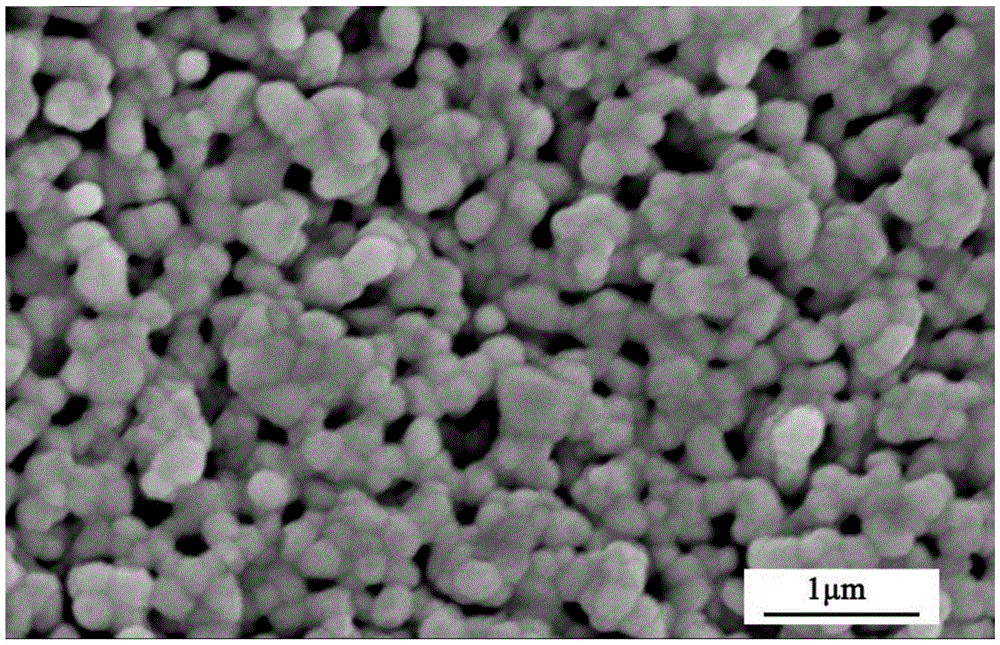

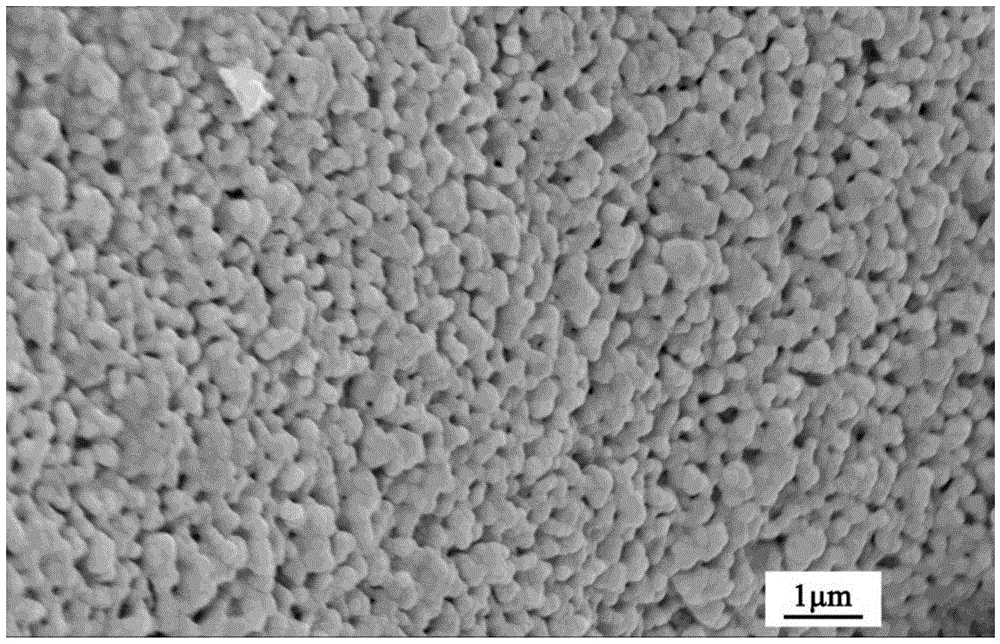

[0025] 1) heating the porous ceramic body with a porosity of 70% to 90% to 1000°C at a heating rate of 5°C / min;

[0026] 2) Apply an electric field strength of 5V / cm to the porous ceramic body that has been heated to 1000°C. When the power supply state jumps from a constant voltage state to a constant current state, adjust the current density to 80mA / mm 2 , jump to the cooling program after timing for 10s, and cool down to room temperature at 5°C / min to obtain a zirconia porous ceramic with a porosity of 80% and a compressive strength of 9MPa.

Embodiment 2

[0028] 1) Raise the porous ceramic body with a porosity of 70% to 90% to 1000°C at a heating rate of 5°C / min;

[0029] 2) Apply an electric field strength of 5V / cm to the porous ceramic body that has been heated to 1000°C. When the power supply state jumps from a constant voltage state to a constant current state, adjust the current density to 80mA / mm 2 , jump to the cooling program after timing for 30s, and cool down to room temperature at 5°C / min to obtain a zirconia porous ceramic with a porosity of 79% and a compressive strength of 9.5MPa.

Embodiment 3

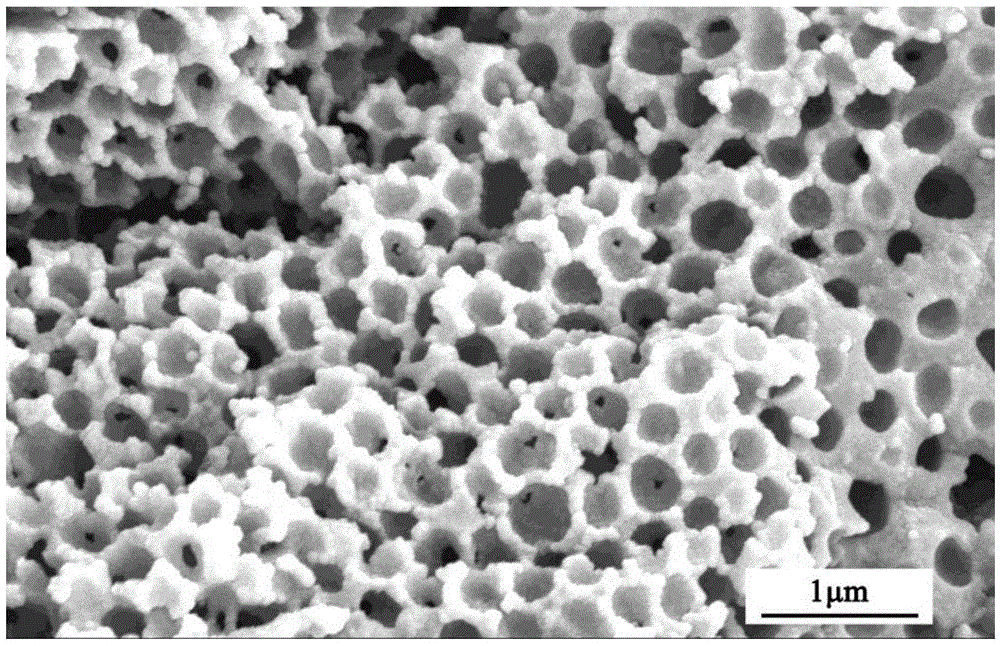

[0031] 1) Raise the porous ceramic body with a porosity of 70% to 90% to 950°C at a heating rate of 5°C / min;

[0032] 2) Apply an electric field strength of 200V / cm to the porous ceramic body that has been heated to 950°C. When the power supply state jumps from a constant voltage state to a constant current state, adjust the current density to 500mA / mm 2 , jump to the cooling program after timing for 30s, and cool down to room temperature at 5°C / min to obtain a zirconia porous ceramic with a porosity of 85% and a compressive strength of 7MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com