Rare-earth permanent magnet material mixed with bayan obo co-existence and associated crude ores and method for manufacturing rare-earth permanent magnet material

A technology of mixing rare earths and rare earth permanent magnets, which is applied in the fields of magnetic materials, inorganic materials, inductors/transformers/magnets, etc., can solve ecological environmental pollution, waste of resources, and failure to consider the natural formula attributes of rare earth elements. Achieve the effect of reducing environmental pollution and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

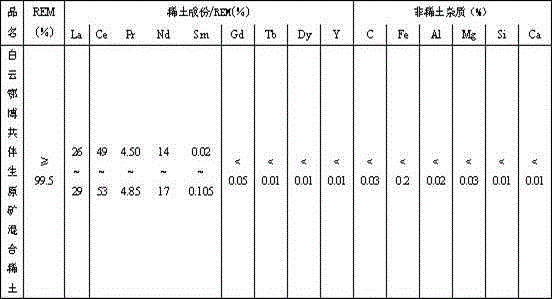

[0063] A kind of sintered rare earth permanent magnet material directly prepared by using Baiyan Obo co-associated raw ore mixed rare earth.

[0064] The ingredients are as follows according to Table 2:

[0065] Table 2

[0066] Element Baiyan Obo co-associated raw ore mixed rare earth Fe B weight percentage 35 64 1

[0067] Using powder metallurgy technology, the raw materials containing a certain proportion, such as Baiyun Obo co-associated raw ore mixed rare earth, ferroboron, etc., are smelted into alloy steel ingots by induction melting furnace, and then crushed to make 3-5μm powder, and NdCu is added to it Nano auxiliary alloy particles, wherein the addition of NdCu nano auxiliary alloy particles is as shown in Table 3 based on the weight of the alloy steel ingot as 100%, and the weight percentage is as shown in Table 3, and it is pressed and formed in a magnetic field. After forming, it is sintered and compacted in a vacuum furnace. Temper. ...

Embodiment 2

[0072] Table 4

[0073] method B r (kGs) h cj (kOe) BH max (MGOe) Rare ore mixed rare earth 11.23 7.02 18.37 Ordinary mixed rare earth 10.65 5.87 15.38

[0074] It can be seen from Table 4 of Example 2 that under the same formula and process conditions, the performance of using common mixed rare earths is far lower than that of using Baiyan Obo co-associated ore mixed rare earths.

Embodiment 3

[0076] table 5

[0077] method Ce content La content B r (kGs) h cj (kOe) BH max (MGOe) Add La alone 0.9% 11.1 8.91 25 Add Ce alone 35% 11.36 6.47 25.94 Baiyun Obo co-associated raw ore mixed rare earth magnet 18.75% 9.06% 11.33 8.69 25.92

[0078] From Table 5 of Example 3, it can be seen that under the condition of similar magnet performance, the utilization rate of lanthanum in the mixed rare earths in the Baiyan Obo co-associated ore is 10 times that of adding lanthanum alone, which can effectively solve the problem of comprehensive utilization of high-abundance rare earths . And the performance of using common mixed rare earths is far lower than that of using Baiyan Obo co-associated raw ore mixed rare earths.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com