Monocrystal-like lithium battery ternary cathode material and preparation method thereof

A positive electrode material, lithium battery technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of new material interface exposure, failure to achieve coating effect, secondary ball rupture, etc., to reduce sintering time, reduce The effect of sintering times and accelerated diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Nickel sulfate, cobalt sulfate and manganese sulfate are made into mixed solution according to Ni:Co:Mn molar ratio is 0.5:0.2:0.3 and mixes evenly, the total number of moles of Ni, Co, Mn three kinds of transition metal ions is 2mol / L, then Add 4mol / L NaOH solution, transition metal ion solution and 4mol / L ammonia water to the reaction vessel at the same time, control the pH value of the reaction system to 11.5, and the reaction temperature to 60°C, and control the reaction time so that the generated Ni 0.5 co 0.2 mn 0.3 (OH) 2 Particle size D 50 It is 3.5 μm, and the particle size distribution conforms to the normal distribution. Then, the obtained precipitate was filtered, washed, and dried at 120° C. for 12 hours. Lithium carbonate and Ni 0.5 co 0.2 mn 0.3 (OH) 2 According to Li / X=1.12 (X=Ni 0.5 co 0.2 mn 0.3 (OH) 2 ) ratio for mixing, while adding lithium carbonate and Ni 0.5 co 0.2 mn 0.3 (OH) 21% KCl in total mass. After mixing evenly, calcinate ...

Embodiment 2

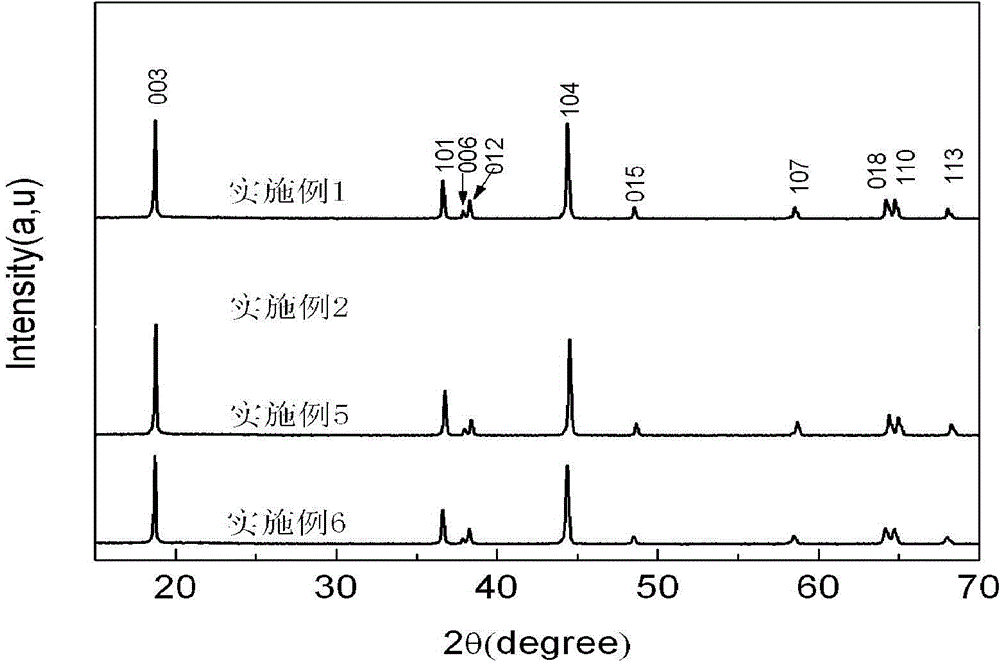

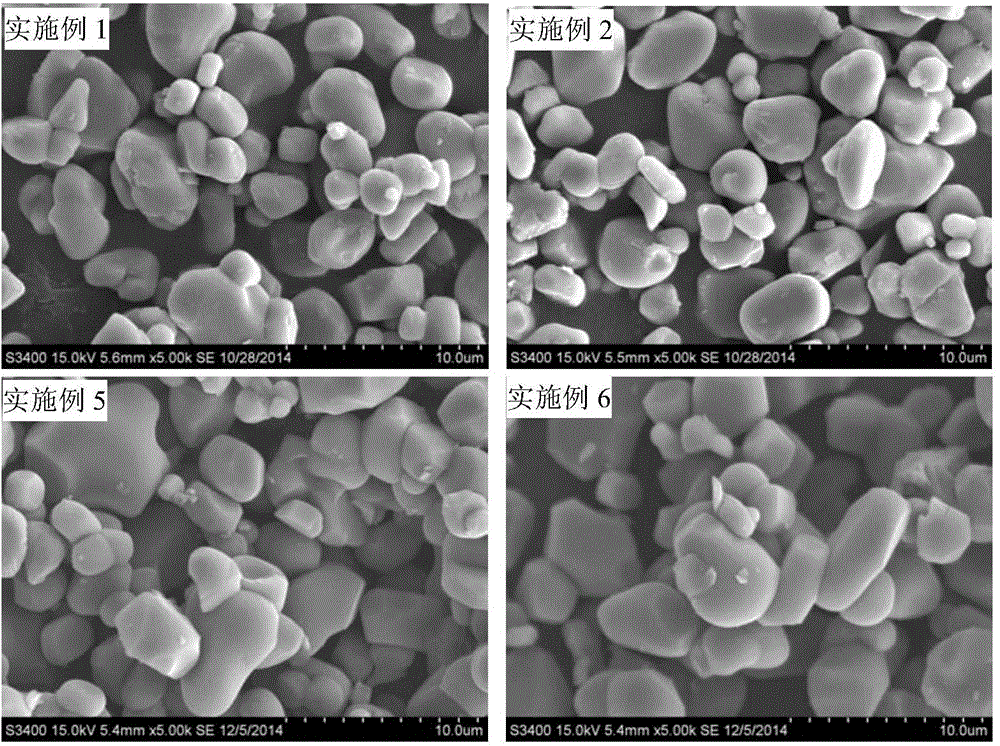

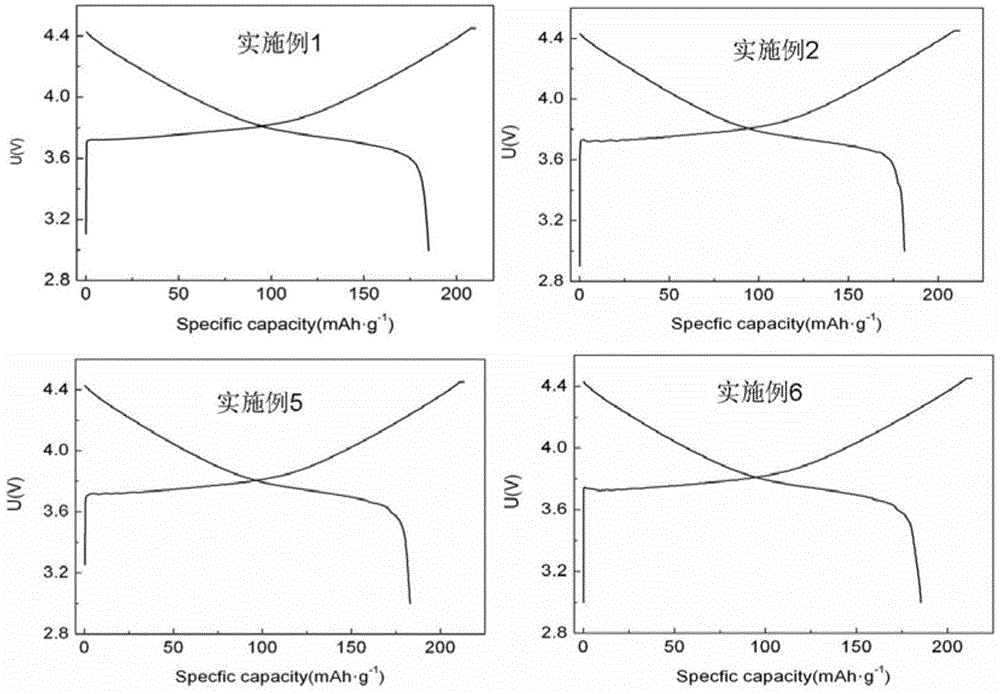

[0027] Lithium carbonate and Ni 0.5 co 0.2 mn 0.3 (OH) 2 Mix according to the ratio of Li / X=1.12, add lithium carbonate and Ni at the same time 0.5 co 0.2 mn 0.3 (OH) 2 3% KCl in total mass. Other steps are the same as in Example 1. The XRD pattern and SEM pattern of the material are as follows figure 1 , figure 2 shown. The results show that the obtained cathode material is a pure phase with good crystallinity. SEM images show that the material has an obvious single-crystal morphology, and the particle size is 2-5 μm. The battery made of this positive electrode material is charged and discharged at a rate of 0.1C (1C capacity 180mAh / g) in the voltage range of 2.9 to 4.45V. The charge and discharge curve is as follows image 3 As shown, the first discharge capacity of the material reaches 182mAh / g.

Embodiment 3

[0029] Lithium nitrate and Ni 0.5 co 0.2 mn 0.3 (OH) 2 Mix according to the ratio of Li / X=1.12, add lithium nitrate and Ni at the same time 0.5 co 0.2 mn 0.3 (OH) 2 5% KCl in total mass. Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com