Ceramic filter membrane prepared from red mud, and preparation method thereof

A ceramic filter membrane, red mud technology, applied in ceramic products, ceramic material production, chemical instruments and methods, etc., can solve the problems of high cost of ceramic filter membrane, high sintering temperature, high hardness of alumina, and achieve superior performance, The effect of cost reduction and great development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

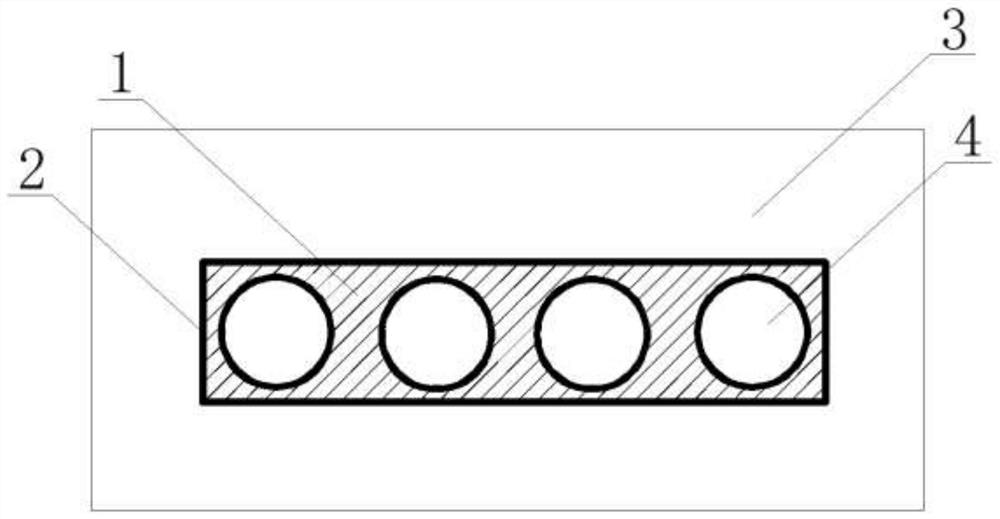

Image

Examples

Embodiment 1

[0048] 60 g of red mud was sand-milled to obtain 120 g of red mud slurry, and the solid content of the red mud slurry was 50 wt%. The red mud slurry was subjected to spray granulation, and a centrifugal spray granulator was used to obtain 45um red mud microspheres, and the obtained red mud microspheres were heat-treated in a heating furnace at 950°C for 45 minutes. Lightly burnt red mud microspheres, 7g of granite stone sawn mud, 5g of kaolin, 4g of PVA, and 1g of glycerin were mixed into plastic mud.

[0049] 60 g of red mud was sand-milled to obtain 180 g of red mud slurry, and the solid content of the red mud slurry was 30 wt%. The red mud slurry was subjected to spray granulation, and a centrifugal spray granulator was used to obtain 10um red mud microspheres, and the obtained red mud microspheres were heat-treated in a heating furnace at 950°C for 45 minutes. Mix lightly burned red mud microspheres, 7g of granite stone sawing mud, 5g of kaolin, and 0.1g of sodium polyacr...

Embodiment 2

[0052] 60 g of red mud was sand-milled to obtain 100 g of red mud slurry, and the solid content of the red mud slurry was 60 wt%. The red mud slurry was subjected to spray granulation, and a centrifugal spray granulator was used to obtain 60um red mud microspheres, and the obtained red mud microspheres were heat-treated in a heating furnace at 1000°C for 60 minutes. Lightly burnt red mud microspheres, 15g of granite stone saw mud, 12g of kaolin, 7g of PVB, and 2g of glycerin are kneaded into plastic clay.

[0053] 60 g of red mud was sand-milled to obtain 150 g of red mud slurry, and the solid content of the red mud slurry was 40 wt%. The red mud slurry is subjected to spray granulation, and a centrifugal spray granulator is used to obtain 20um red mud microspheres, and the obtained red mud microspheres are heat-treated in a heating furnace at 1000°C for 60 minutes. Mix lightly burned red mud microspheres, 15g of granite stone sawing mud, 12g of kaolin, and 0.5g of sodium pol...

Embodiment 3

[0056] 55 g of red mud was sand-milled to obtain 100 g of red mud slurry, and the solid content of the red mud slurry was 55 wt%. The red mud slurry was subjected to spray granulation, and a centrifugal spray granulator was used to obtain 50um red mud microspheres, and the obtained red mud microspheres were heat-treated in a heating furnace at 980°C for 50 minutes. Mix lightly burned red mud microspheres, 10g granite stone sawn mud, 10g Suzhou soil, 5g PVA, and 1.5g glycerin to form plastic clay.

[0057] 70 g of red mud was sand-milled to obtain 200 g of red mud slurry, and the solid content of the red mud slurry was 35 wt%. The red mud slurry was subjected to spray granulation, and a centrifugal spray granulator was used to obtain 15um red mud microspheres, and the obtained red mud microspheres were heat-treated in a heating furnace at 980°C for 50 minutes. Mix lightly burned red mud microspheres, 10g of granite stone sawing mud, 10g of kaolin, and 0.3g of sodium polyacryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com