Lithium iron phosphate positive electrode material, preparation method thereof and lithium ion battery

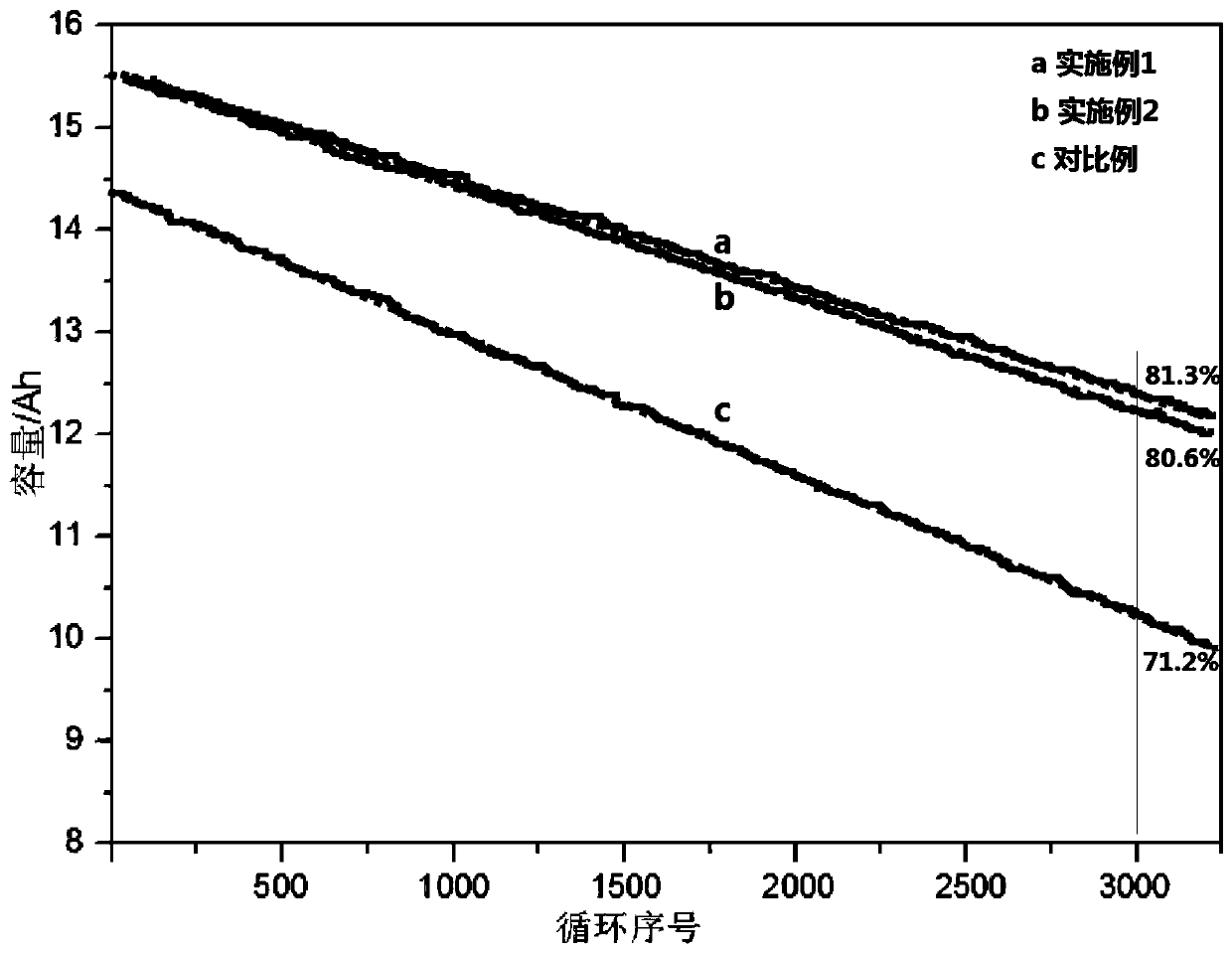

A technology of lithium iron phosphate and positive electrode materials, which is applied in the direction of batteries, battery electrodes, secondary batteries, etc., can solve the problems of poor cycle performance and low compaction density, so as to improve production efficiency, improve compaction performance, and promote long-term big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention discloses a preparation method of lithium iron phosphate positive electrode material, comprising the following steps:

[0026] Stir the deionized water, iron phosphate, lithium carbonate and glucose evenly to obtain a mixed slurry;

[0027] Grinding the mixed slurry once to obtain coarsely ground slurry, and then performing secondary grinding to obtain finely ground slurry;

[0028] performing centrifugal spray drying on the finely ground slurry to obtain a dry material, and mixing the dry material with lithium titanate to obtain a lithium iron phosphate precursor;

[0029] Carrying out solid phase sintering of the lithium iron phosphate precursor in a nitrogen atmosphere to obtain a lithium iron phosphate sintered body;

[0030] The lithium iron phosphate sintered body is subjected to jet crushing and classification to obtain the lithium iron phosphate cathode material.

[0031] In a further scheme, in some embodiments of the p...

Embodiment 1

[0041] Add 20kg of deionized water into the stirring tank, then add 10kg of iron phosphate, 2.45kg of lithium carbonate, and 1kg of glucose, stir and disperse evenly to obtain a mixed slurry with a solid content of 37.23%;

[0042] Transferring the mixed slurry to a coarse grinding mill for primary grinding to obtain a coarse grinding slurry, wherein the particle size of the coarse grinding slurry is D50=21 μm, D97=75 μm;

[0043] Transferring the coarsely ground slurry to a fine grinding mill for secondary grinding to obtain a finely ground slurry, wherein the particle size of the finely ground slurry is D10=236nm, D50=524nm, D97=2.11 μm;

[0044] performing centrifugal spray drying on the finely ground slurry to obtain dry material;

[0045] The dry material is mixed with lithium titanate at a mass ratio of 1:0.005 and uniformly coated to obtain a lithium iron phosphate precursor;

[0046] The lithium iron phosphate precursor is subjected to high-temperature solid-state sin...

Embodiment 2

[0049] Add 15kg of deionized water into the stirred tank, then add 10kg of ferric phosphate, 2.52kg of lithium carbonate, and 1.1kg of glucose, stir and disperse evenly to obtain a mixed slurry with a solid content of 43.75%;

[0050] The mixed slurry was transferred to a coarse sand mill for primary grinding to obtain a coarsely ground slurry, wherein the particle size of the coarsely ground slurry was D50=20 μm and D100=73 μm.

[0051] Transferring the coarsely ground slurry to a fine grinding mill for secondary grinding to obtain a finely ground slurry, wherein the particle size of the finely ground slurry is D10=231nm, D50=603nm, D97=1.96 μm;

[0052] performing centrifugal spray drying on the finely ground slurry to obtain dry material;

[0053] The dry material is mixed with lithium titanate at a mass ratio of 1:0.003 and uniformly coated to obtain a lithium iron phosphate precursor;

[0054]The lithium iron phosphate precursor is subjected to high-temperature solid-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com