Device and method for monitoring corn precision seeding operation

A technology for precision seeding and corn, applied in the field of agricultural engineering, can solve problems such as loss of seeding operations, and achieve the effects of improved sensitivity, high sensitivity, and optimal fault alarm sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

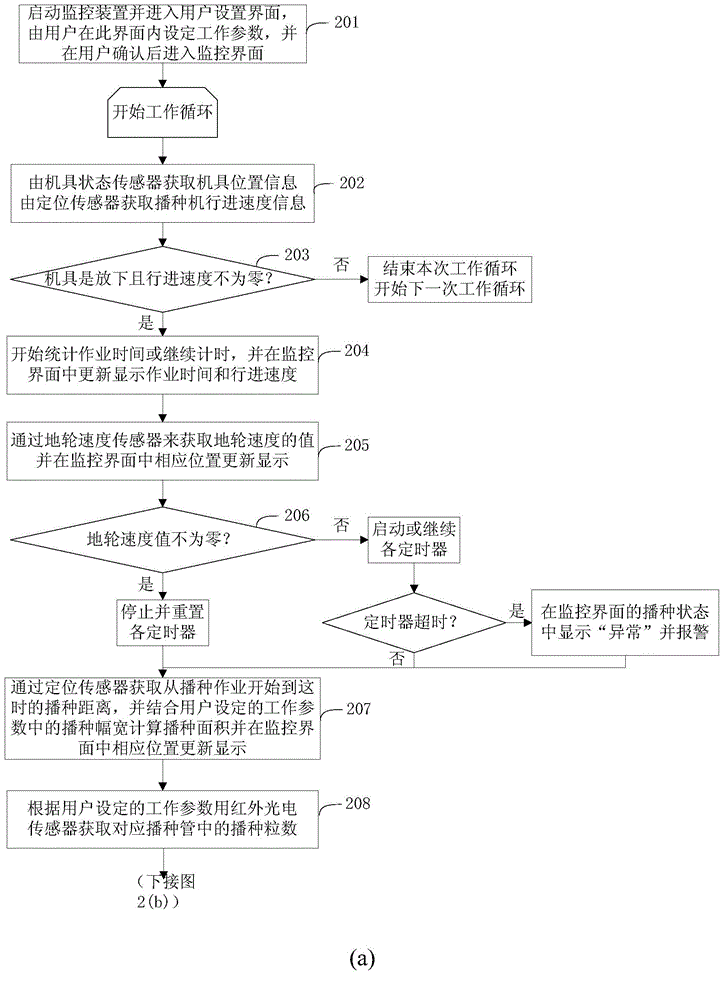

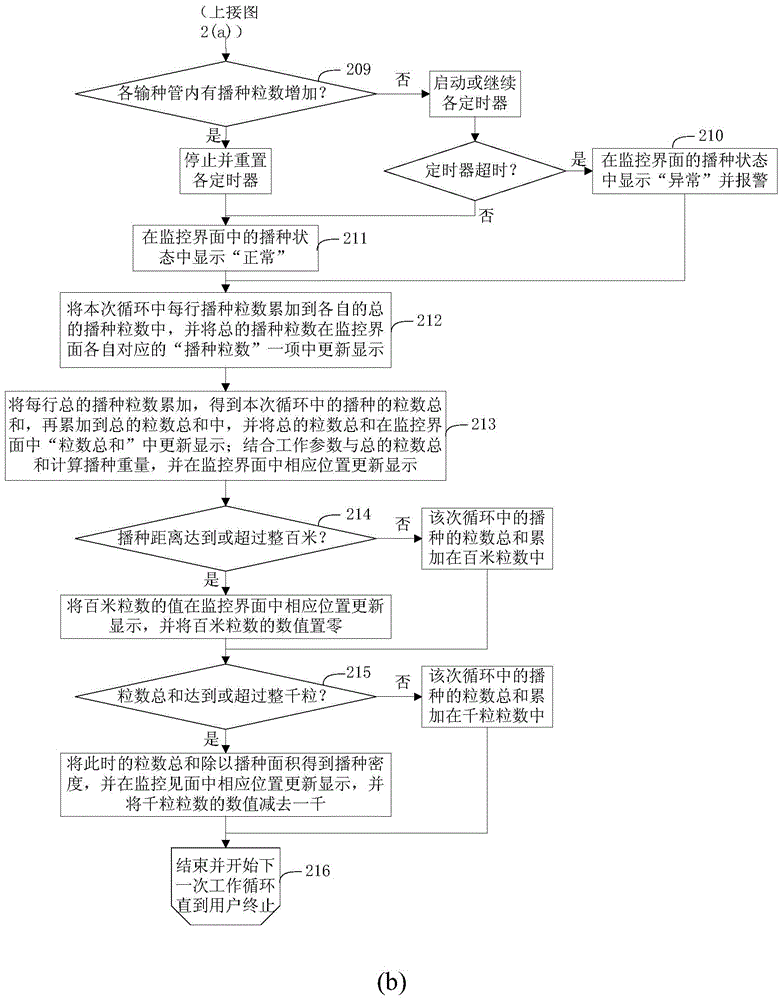

[0045] The embodiment of the present invention proposes a method for monitoring precision corn seeding operations, see figure 2 , the method includes performing the following steps in the monitoring device:

[0046]Step 201: Start the monitoring device and enter the user setting interface, where the user sets operation parameters, and enters the monitoring interface after confirmation by the user.

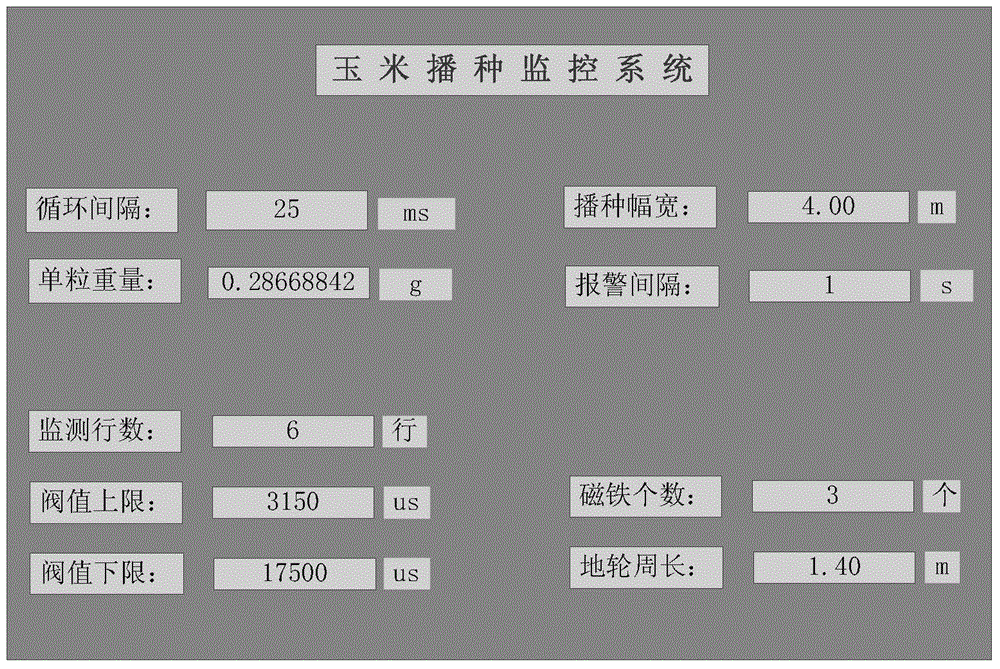

[0047] The operating parameters specifically include: single grain weight, alarm interval, number of monitoring rows, upper threshold, lower threshold, sowing width, cycle interval, number of magnets and circumference of the ground wheel. All job parameters are set with default values (e.g. figure 1 shown) to ensure the normal operation of the monitoring device, when the user sets the operating parameters, the operating parameters are updated from the default value to the set value set by the user.

[0048] After the setting is completed, the user interface is transferred to t...

Embodiment 2

[0090] The embodiment of the present invention proposes a device for monitoring the precise sowing operation of corn, and the device includes:

[0091] A seven-inch LCD touch screen and a set of buttons are used to output operation status parameters to the user, and can also be used for the user to input operation parameters. For the user interface, see figure 1 , Figure 4 and Figure 5 .

[0092] The six-way infrared photoelectric sensor is used to obtain the information of the number of seeds sown in the six-row seed delivery tube.

[0093] The six-way input capture circuit is used to process and collect signals from the sowing monitoring sensor indicating the number of sowing grains of the six rows of seeding pipes, and output them to the microprocessor.

[0094] One ground wheel speed sensor is used to obtain information representing the ground wheel speed.

[0095] One external interrupt circuit is used to process and collect the signal representing the ground wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com