Polyamide composition for quick injection molding and preparation method thereof

A polyamide composition and polyamide technology are applied in the field of rapid injection molding polyamide composition and its preparation, and can solve the problems of crystal structure, different crystallization mechanism, long curing time, poor demoulding and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

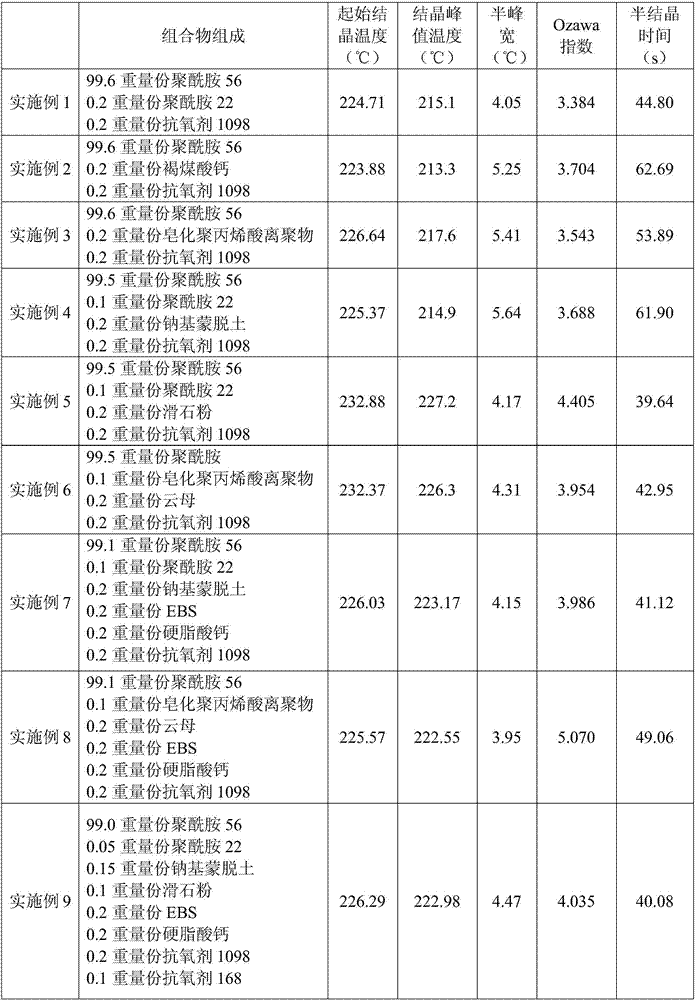

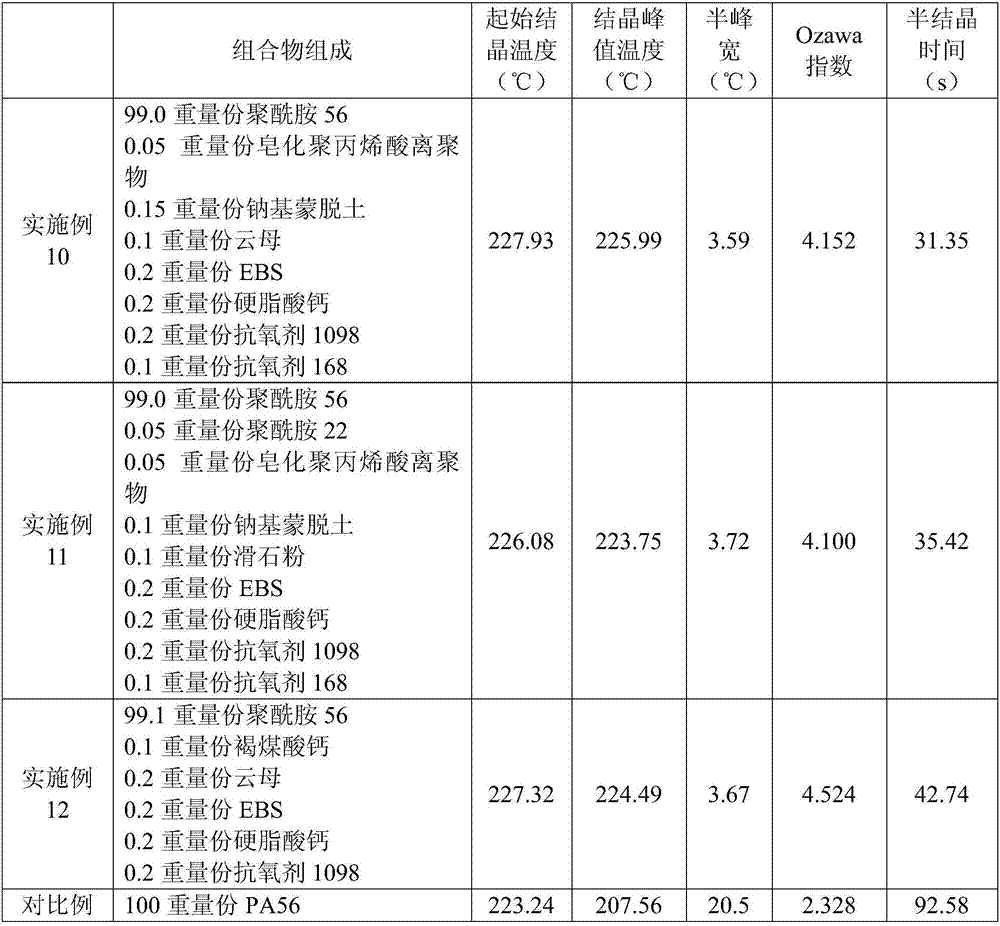

Examples

Embodiment Construction

[0040] The invention provides a polyamide composition and a preparation method thereof.

[0041]

[0042] Including the following parts by weight:

[0043] Polyamide resin: 95-100 parts by weight, preferably 95-99.9 parts by weight, more preferably 99-99.9 parts by weight;

[0044] Nucleating agent: 0.5 parts by weight or less, preferably 0.005-0.5 parts by weight, more preferably 0.005-0.03 parts by weight.

[0045] Wherein, the polyamide resin includes polyamide 5X resin.

[0046] According to specific circumstances, the polyamide composition may also include 0.05-1 part by weight of lubricant and / or 0.05-1 part of antioxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com