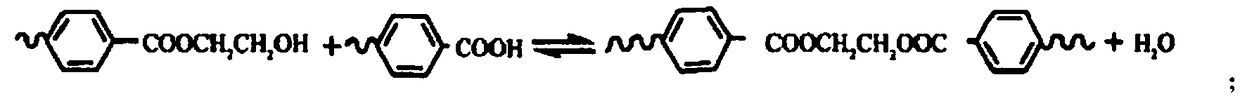

Homogeneous hyper-viscous polyester and preparation method thereof

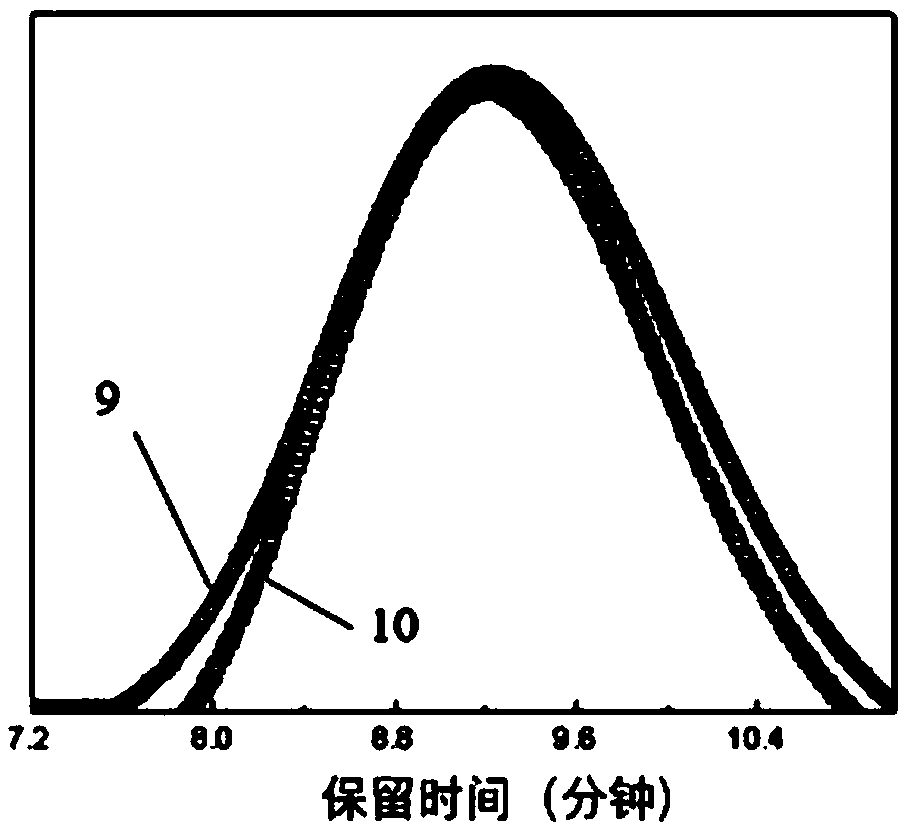

A technology of viscous polyester and intrinsic viscosity, applied in the field of homogeneous high-viscosity polyester and its preparation, can solve the problems of high oligomer content and insufficient homogenization, achieve narrow molecular weight distribution width, reduce probability, avoid low The effect of increased polymer content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation method of homogeneous high viscosity polyester, concrete steps are as follows:

[0052] (1) prepare low-viscosity polyester;

[0053] (1.1) Modulation of ethylene glycol antimony;

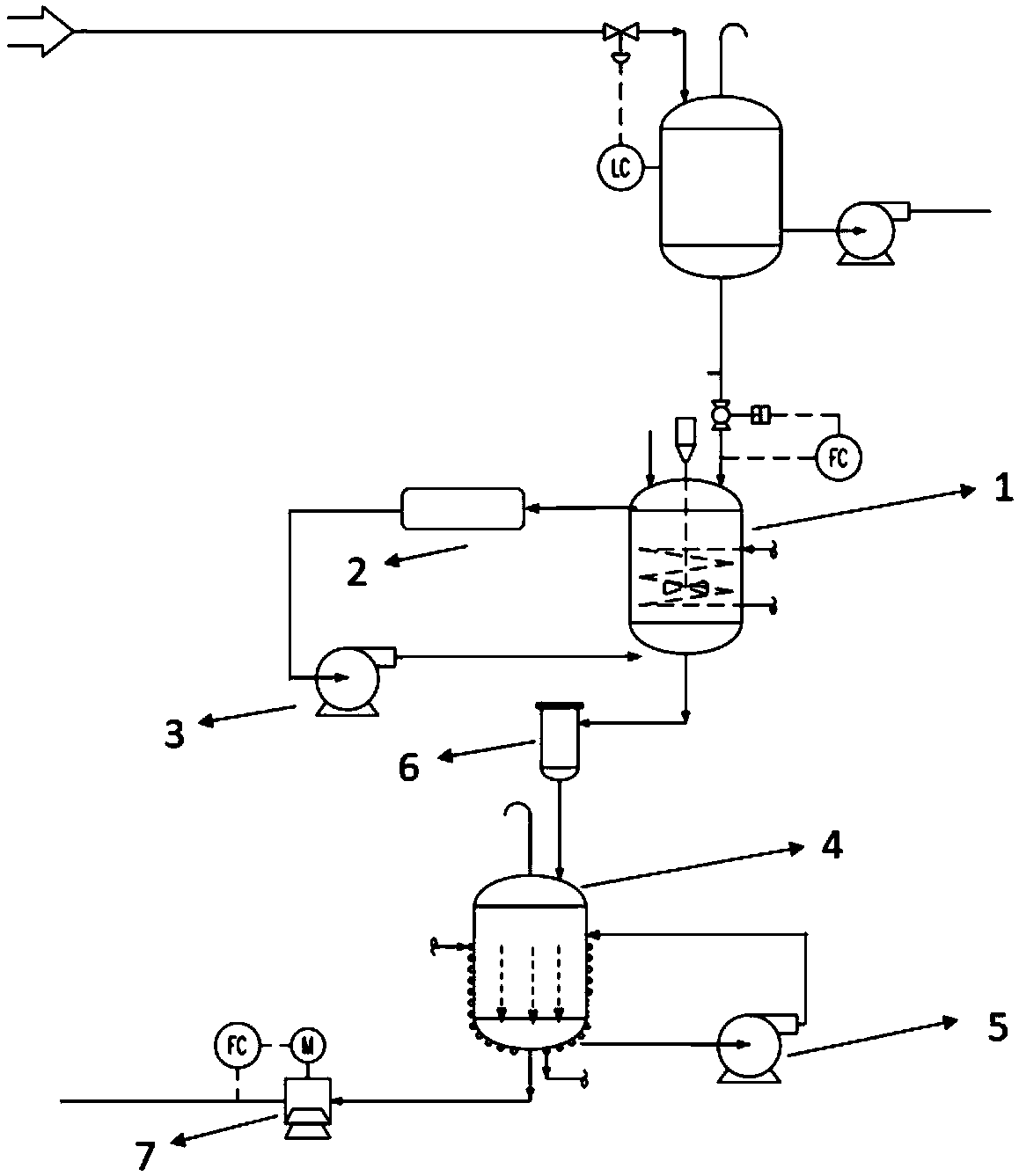

[0054]Ethylene glycol antimony and ethylene glycol are mixed uniformly in the catalyst preparation tank 1, and nitrogen gas with a water content of 155ppm is circulated in the mixing process; the catalyst configuration system diagram is as follows figure 2 As shown, the catalyst configuration system includes a catalyst preparation tank 1 and a catalyst supply tank 4. The inside of the catalyst preparation tank 1 is provided with an agitator, and the top and bottom are respectively connected with the outlet of the nitrogen treatment generator 2 and the gas circulation pump 3. 2 is used to generate nitrogen and dry nitrogen at the same time. The nitrogen treatment generator 2 is connected to the inlet of the gas circulation pump 3; after the modulation process is completed, e...

Embodiment 2

[0066] The preparation method of homogeneous high viscosity polyester, concrete steps are as follows:

[0067] (1) prepare low-viscosity polyester;

[0068] (1.1) Modulation of ethylene glycol antimony;

[0069] Antimony ethylene glycol and ethylene glycol are mixed evenly in the catalyst preparation tank, wherein, in the mixing process, helium with a water content of 190ppm is circulated, and the configuration system of the catalyst is basically the same as that of Example 1, except that The device used to generate gas while drying the gas is a helium gas treatment generator;

[0070] (1.2) Carry out esterification reaction and polycondensation reaction between terephthalic acid and ethylene glycol with a molar ratio of 1:1.3, add ethylene glycol antimony when the average degree of polymerization of the intermediate product of the polycondensation reaction reaches 8, and finally obtain low Viscous PET, wherein the temperature of the esterification reaction is 238°C, the tim...

Embodiment 3

[0077] The preparation method of homogeneous high viscosity polyester, concrete steps are as follows:

[0078] (1) prepare low-viscosity polyester;

[0079] (1.1) Modulation of ethylene glycol antimony;

[0080] Ethylene glycol antimony and ethylene glycol are mixed evenly in the catalyst preparation tank, wherein, in the mixing process, the neon gas with a water content of 185ppm is circulated, and the configuration system of the catalyst is basically the same as that of Example 1, the difference is that The device used to generate gas while drying the gas is a neon gas treatment generator;

[0081] (1.2) Carry out esterification reaction and polycondensation reaction between terephthalic acid and ethylene glycol with a molar ratio of 1:1.4, add ethylene glycol antimony when the average degree of polymerization of the intermediate product of the polycondensation reaction reaches 13, and finally obtain low Viscous PET, wherein the temperature of the esterification reaction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com