Low-fiber-floating glass-fiber-reinforced toughening polypropylene composite material and preparation method thereof

A composite material, reinforcement and toughening technology, applied in the field of polyolefin, can solve the problems of not too much glass fiber content, obvious floating fiber problem, bad appearance of parts, etc., and achieve good dimensional stability, high impact resistance, and promote crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

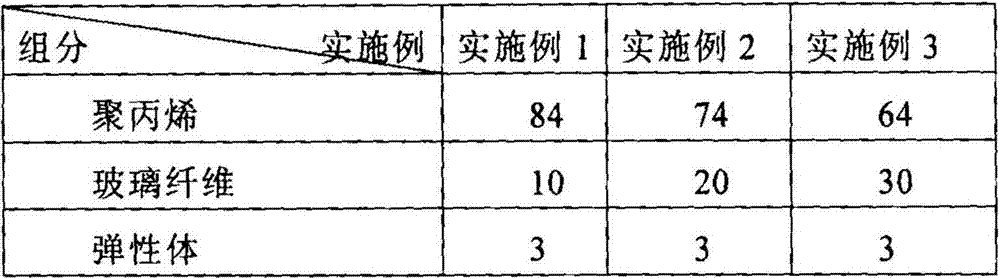

[0032] In order to achieve the above-mentioned second purpose, the technical solution adopted by the present invention is: the preparation method of the low-floating fiber glass fiber reinforced toughened polypropylene composite material comprises the following steps: weighing raw materials according to the proportion; removing the glass fiber The other components are mixed in a high-speed mixer for 5-10 minutes, and the glass fiber is fed into the extruder through the side feeding port, extruded by a twin-screw machine, cooled and granulated, and finally the granules are dried to obtain a low-floating Fiberglass reinforced toughened polypropylene composites.

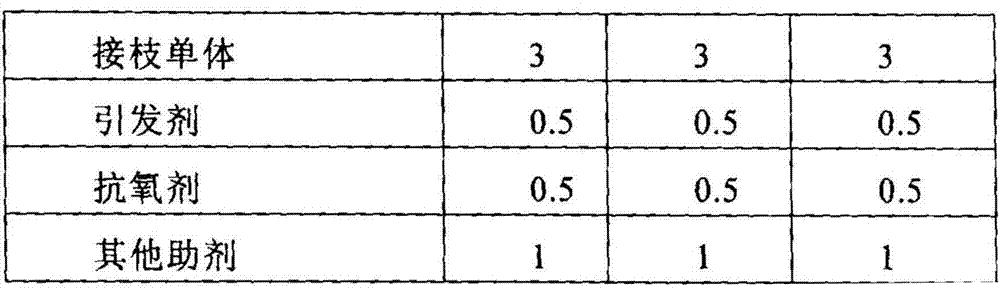

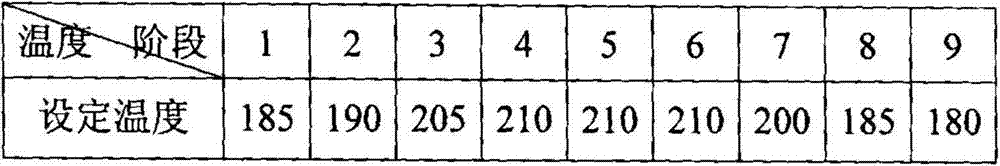

[0033] The speed of the twin-screw extruder is 200-500r / min, and the temperature of the extruder from feeding to the machine head is set as: 185°C, 190°C, 205°C, 210°C, 210°C, 210°C, 200°C , 185°C, 180°C, vacuum degree ≤0.06MPa.

Embodiment 1

[0039] (1) Raw materials are weighed in parts by weight: polypropylene 84, elastomer 3, graft monomer 3, initiator 0.5, antioxidant 0.5, other additives 1;

[0040] (2) Polypropylene, elastomer, graft monomer, initiator, antioxidant and other auxiliary agents are placed in a high mixer and mixed for 10 minutes;

[0041] (3) Put the material into the twin-screw extruder, control the feeding speed, and feed glass fiber into the extruder through the side feeding port; control the number of glass fibers and feeding speed, and control the glass fiber content 10. For granulation, the rotational speed of the twin-screw machine is 300 rpm: the twin-screw extrusion process is listed in Table 2.

[0042] Table 2: Twin-screw extrusion process

[0043]

Embodiment 2

[0045](1) Raw materials are weighed in parts by weight: polypropylene 74, elastomer 3, graft monomer 3, initiator 0.5, antioxidant 0.5, other additives 1;

[0046] (2) Polypropylene, elastomer, graft monomer, initiator, antioxidant and other auxiliary agents are placed in a high mixer and mixed for 10 minutes;

[0047] (3) Put the material into the twin-screw extruder, control the feeding speed, and feed glass fiber into the extruder through the side feeding port; control the number of glass fibers and feeding speed, and control the glass fiber content to 20%. For granulation, the rotational speed of the twin-screw machine is 300 rpm; the twin-screw extrusion process is listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com