Method for adhering sericin and nanometer material on real silk fabric

A technology of silk fabrics and nanomaterials, applied in the field of fixing sericin and nanomaterials on silk fabrics, and in the field of functional textile processing, can solve the problem that the dispersion of functional nanopowders cannot be effectively solved, affecting the feel and safety of silk fabrics, The nanometer function cannot fully reflect the problems such as, and achieve the effect of being easy to promote and use, reducing water solubility, and high labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

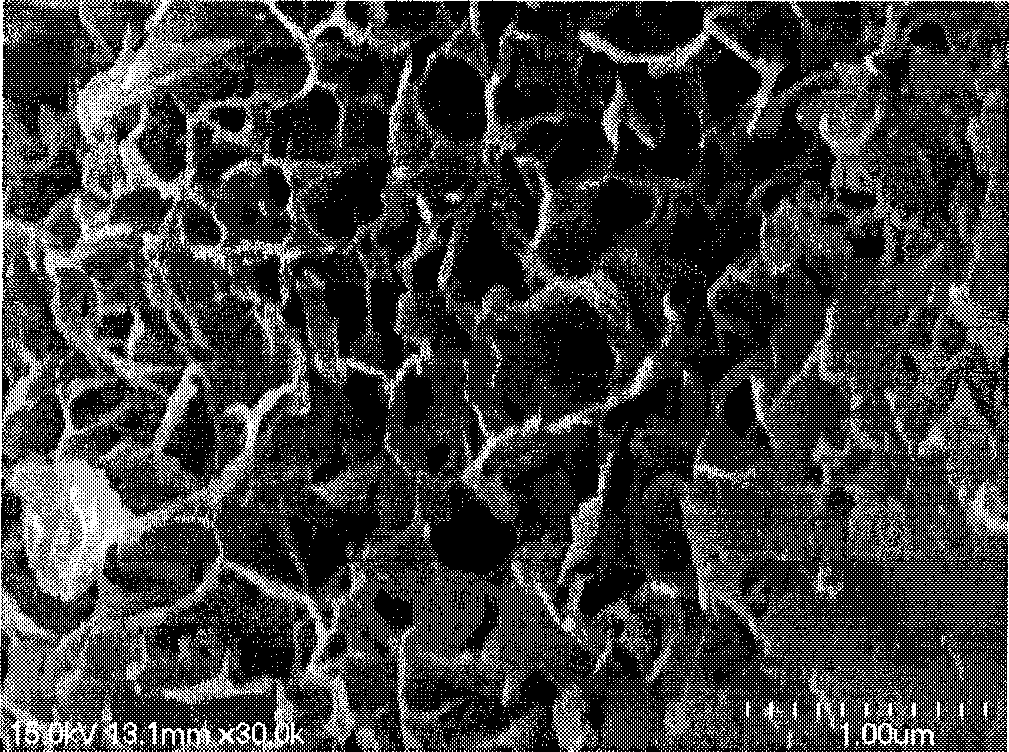

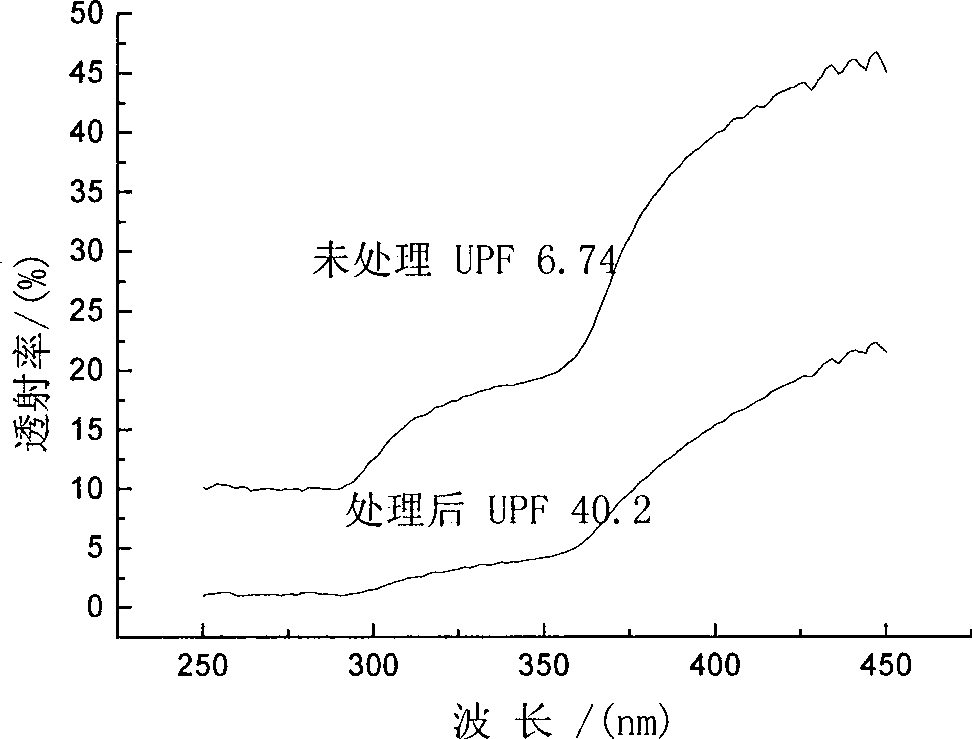

[0022] Immerse the silk gray cloth in the treatment solution composed of sodium carbonate with a pH value of 7.5 and 2709 alkaline protease, and treat it at 50°C for 40 minutes to make the sericin on the surface of the silk gel and produce a slight hydrolysis, and rinse it with warm water at 60°C 1min, the obtained sericin content is 11% and the residual sericin is evenly distributed and the rubber-containing fabric with fluffy structure; the glue-containing fabric is immersed in the water-soluble metal salt Zn(NO 3 ) 2 In the solution, treat at room temperature for 30 minutes, roll off excess water in a rolling car, enter a steam room containing ammonia water / ethanol with a volume ratio of 1:1, treat at 75°C for 60 minutes, and enter a heat setting machine for pre-treatment at 80°C. Bake for 2 minutes at 120°C for 2 minutes; put the fabric in a soap solution containing 3g / L of soda ash and 1g / L of soap at 60 Treat at ℃ for 30 minutes, rinse in clean water, and dry to obtain ...

Embodiment 2

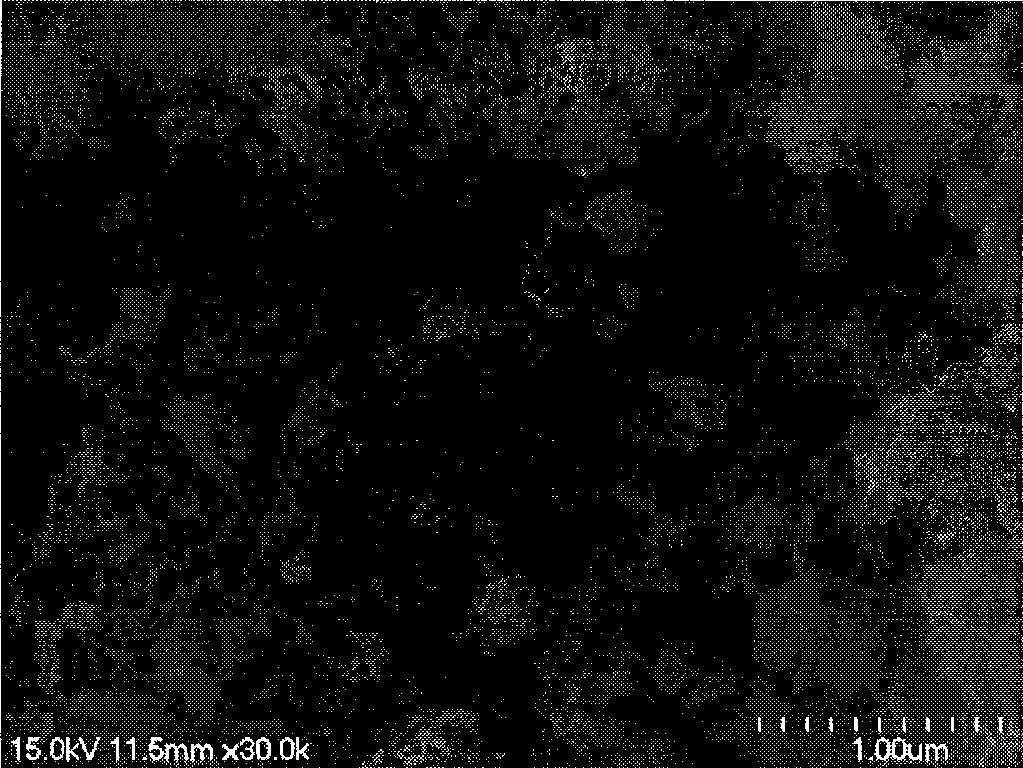

[0029] The silk gray cloth was immersed in a buffered alkaline solution composed of sodium carbonate and sodium bicarbonate with a pH value of 9.8, treated at 78°C for 30 minutes, rinsed with warm water at 60°C for 1 minute, and immersed in 0.3mol / L Zn(NO 3 ) 2 solution, treat at room temperature for 30min, roll off the excess water in the rolling car, enter the steam room containing ammonia water / methanol with a volume ratio of 1:1, treat at 65°C for 60min, and pre-heat at 80°C in the heat setting machine. Bake for 2 minutes at 120°C for 2 minutes; put the fabric in a soap solution containing 3g / L of soda ash and 1g / L of soap at 60 It was treated at ℃ for 30 minutes, then rinsed in clean water, and then dried to obtain the glue-containing nano-functional silk fabric. The test results show that the obtained fabric contains 11 percent sericin, a UPF index of 35, and a bacteriostatic rate of more than 95 percent against Escherichia coli and Staphylococcus aureus.

Embodiment 3

[0031] Immerse the silk fabric in the treatment solution composed of sodium carbonate with a pH value of 7.5 and 2709 alkaline protease, treat it at 50°C for 40 minutes, rinse it with warm water at 60°C for 1 minute, and immerse it in 0.5mol / L Mg(NO 3 ) 2 In the solution, treat at room temperature for 30 minutes, roll off excess water in a paddle car, and then enter a steam chamber containing ammonia water / (ethanol 1 / 2+methanol 1 / 2) at a volume ratio of 2:1, and treat at 70°C for 60 minutes. Pre-bake at 80°C for 2 minutes in a heat setting machine, and bake at 110°C for 4 minutes; put the fabric in 3g / L soda ash and 1g / L at a bath ratio of 1:30 (ratio of fabric weight to washing liquid volume). Treat L soap in a soap alkali solution at 60° C. for 30 minutes, then rinse in clean water, and dry to obtain a glue-containing nano-functional silk fabric. The test results show that the obtained fabric contains 10% sericin, the limited oxygen index is 38, the afterburn time is 0s, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com