Nano-composite material high-wax thick oil pour point-depressing and viscosity-reducing agent and preparation method thereof

A nano-composite material and viscosity reducing agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor low temperature fluidity of heavy oil, and achieve simple and easy control of production process, lower freezing point and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

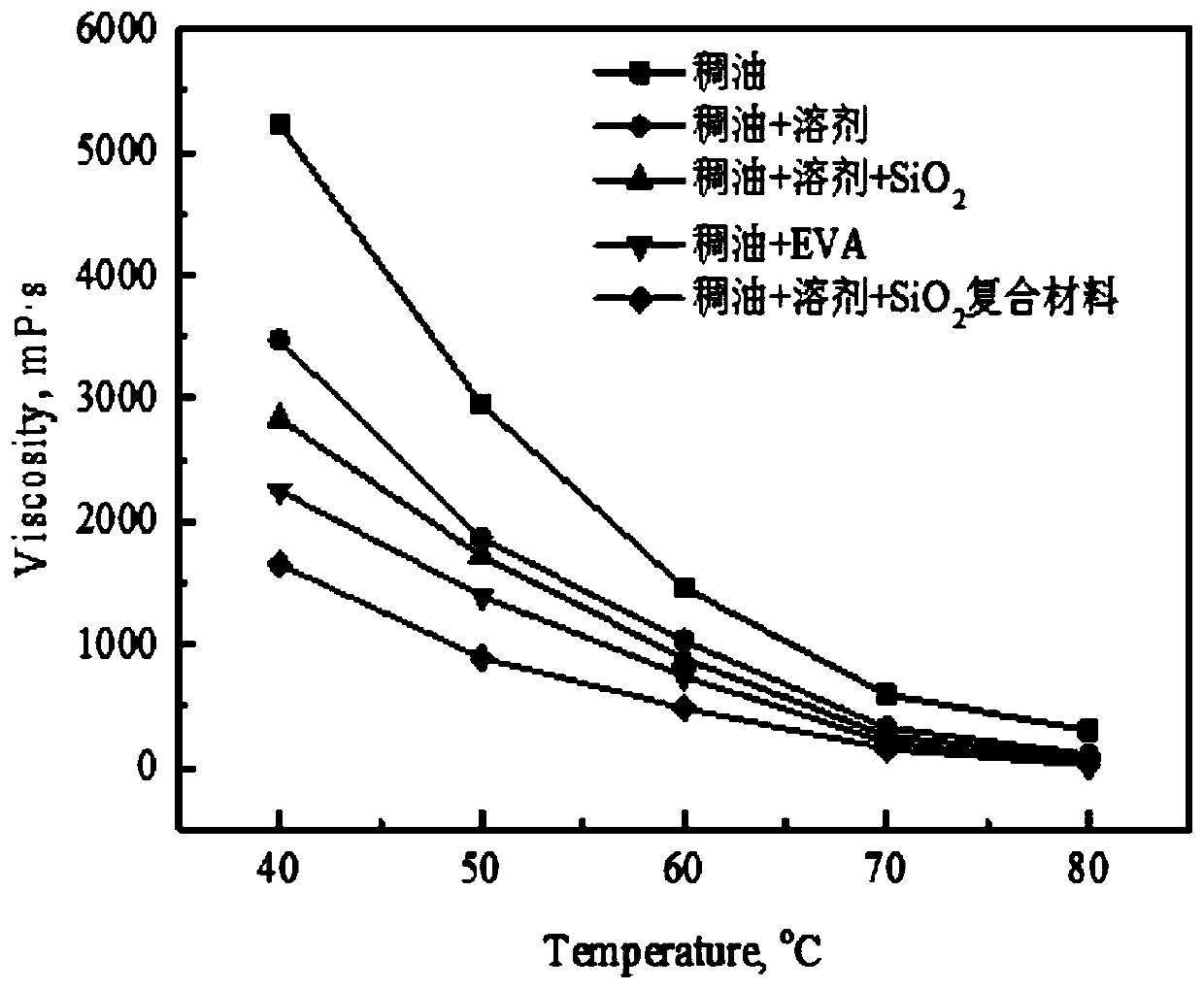

[0031] A preparation method of a nanocomposite high-wax heavy oil pour point and viscosity reducer, comprising the following steps:

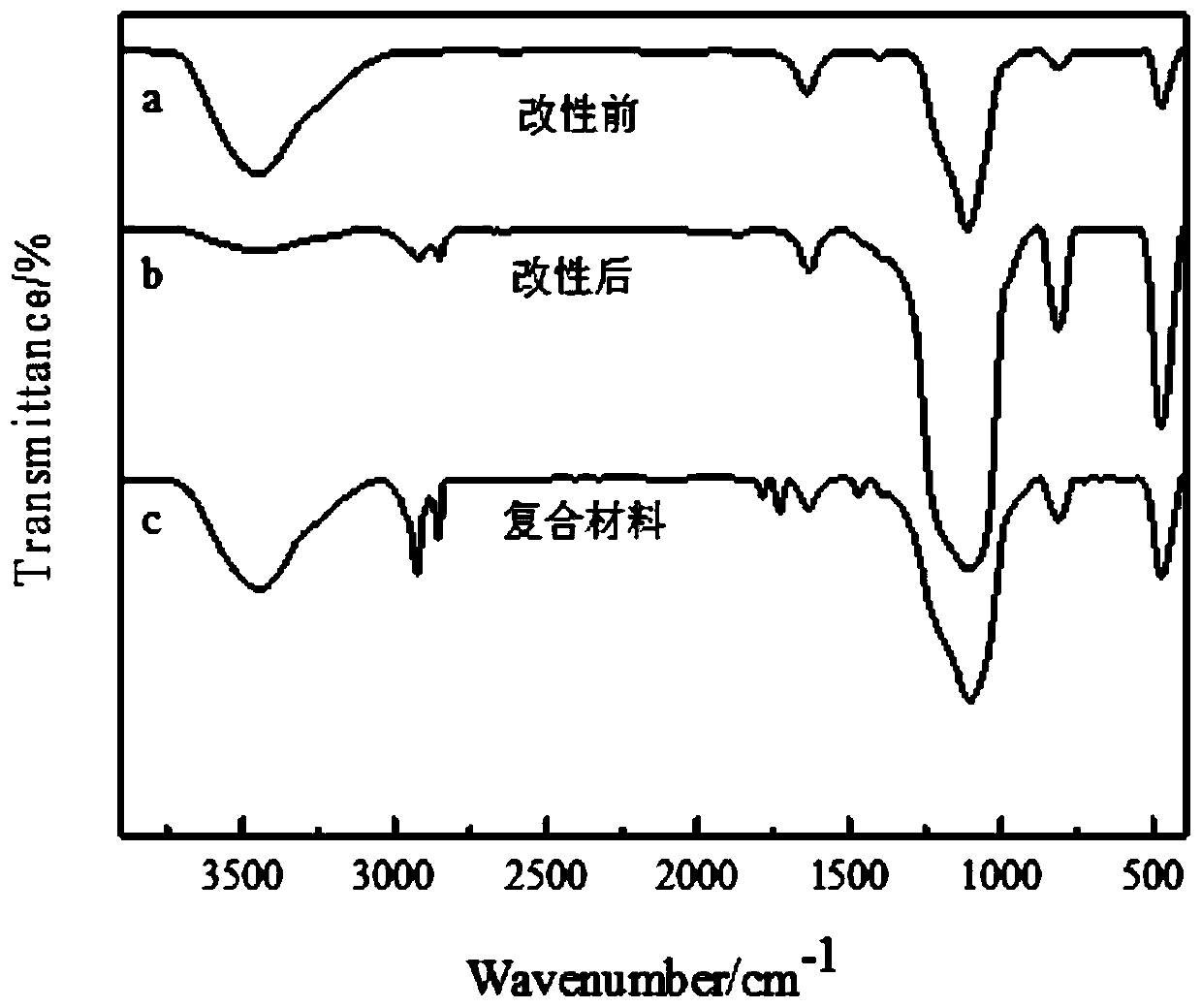

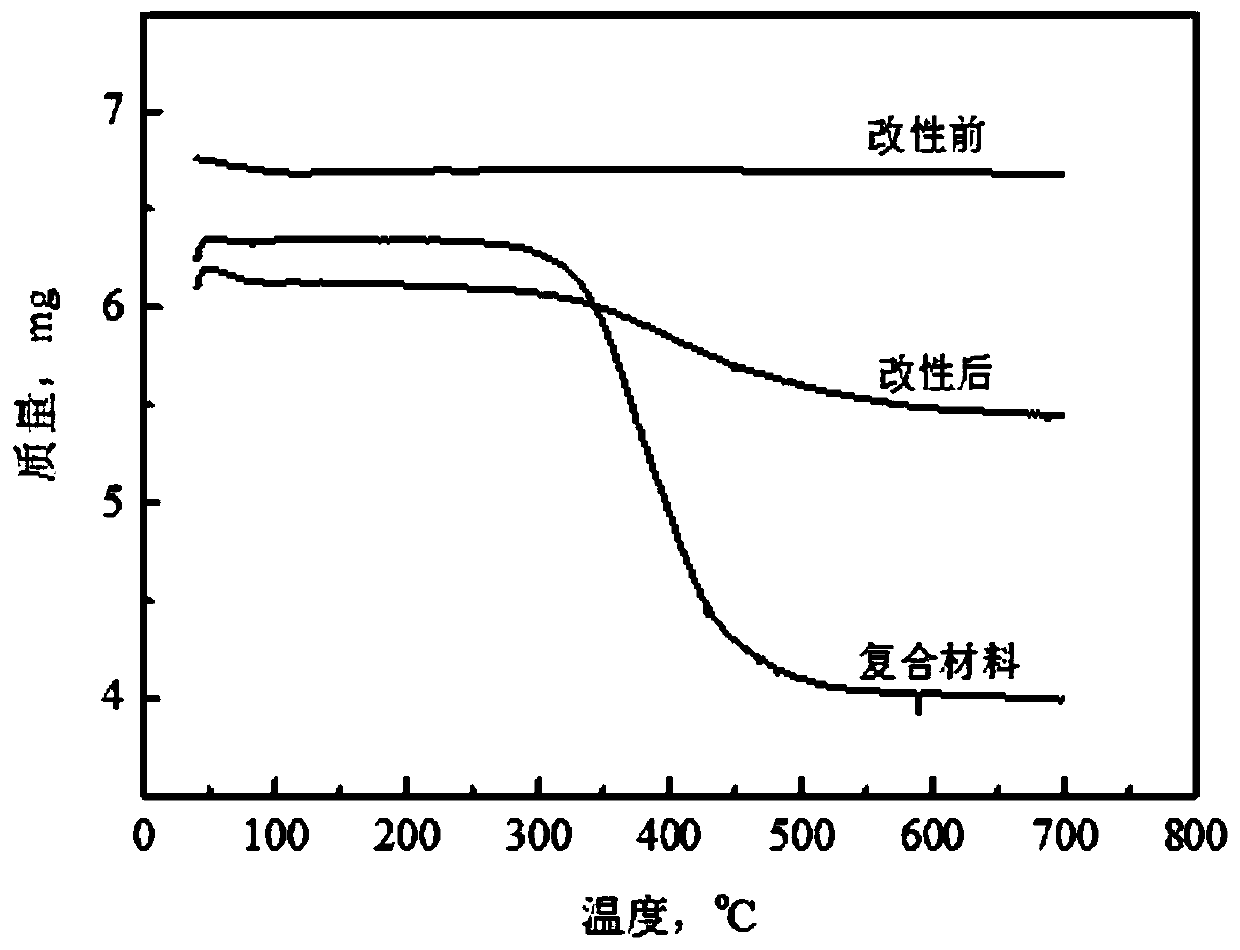

[0032] (1) Add 1mL of KH570 into a mixed solvent of absolute ethanol and distilled water at a volume ratio of 50:1 and stir to dissolve, then add 2.5g of nano-silica, stir and dissolve, then stir and react in a constant temperature oil bath at 80°C for 3 hours, Then centrifuge in sequence, wash with absolute ethanol for 5 times, and dry at 65°C for 12 hours to obtain modified nano-silica;

[0033] (2) Add stearyl methacrylate, maleic anhydride, styrene, and acrylamide to xylene at a molar ratio of 3:1:2:0.5, and then add the modified nano Silica 2.5g, stir and heat to 60°C, then heat up to 80°C for 30min and react for 3h, finally add excess ethanol for precipitation, filter and dry at 60°C to constant weight to obtain nanocomposite material with high waxy consistency Oil pour point and viscosity reducer.

Embodiment 2

[0035] A preparation method of a nanocomposite high-wax heavy oil pour point and viscosity reducer, comprising the following steps:

[0036] (1) Add 1mL of KH570 into a mixed solvent of absolute ethanol and distilled water at a volume ratio of 50:1 and stir to dissolve, then add 2.5g of nano-silica, stir and dissolve, then stir and react in a constant temperature oil bath at 80°C for 3 hours, Then centrifuge in sequence, wash with absolute ethanol for 5 times, and dry at 65°C for 12 hours to obtain modified nano-silica;

[0037] (2) Add stearyl methacrylate, maleic anhydride, styrene, and acrylamide into xylene at a molar ratio of 5:1:2:0.5, and then add the modified nano Silica 2.5g, stirred and heated to 60°C, then heated to 80°C for 2-4 hours after 30 minutes, finally added excess ethanol for precipitation, filtered and dried at 60°C to constant weight to obtain a nanocomposite material with high Pour point and viscosity depressant for waxy thick oil.

Embodiment 3

[0039] A preparation method of a nanocomposite high-wax heavy oil pour point and viscosity reducer, comprising the following steps:

[0040] (1) Add 1mL of KH570 into a mixed solvent of absolute ethanol and distilled water at a volume ratio of 50:1 and stir to dissolve, then add 2.5g of nano-silica, stir and dissolve, then stir and react in a constant temperature oil bath at 80°C for 3 hours, Then centrifuge in sequence, wash with absolute ethanol for 5 times, and dry at 65°C for 12 hours to obtain modified nano-silica;

[0041] (2) Add octadecyl methacrylate, maleic anhydride, styrene, and acrylamide into xylene at a molar ratio of 8:1:2:0.5, and then add the modified nano Silica 2.5g, stirred and heated to 60°C, then heated to 80°C for 2-4 hours after 30 minutes, finally added excess ethanol for precipitation, filtered and dried at 60°C to constant weight to obtain a nanocomposite material with high Pour point and viscosity depressant for waxy thick oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com