Method for improving heat property and crystallization behavior of polylactic acid and its multiple blocked copolymer

A multi-block copolymer and polylactic acid technology, which is applied in the field of improving the thermal properties and crystallization behavior of polylactic acid and its multi-block copolymer, and preparing high-performance polylactic acid materials, to achieve melting point and crystallization temperature improvement, improve processing performance, Effect of heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 1g each of PDLA and PLLA with a weight-average molecular weight of 30000, and dissolve them in 13ml of dichloromethane respectively. Naturally volatilized for 3 days, then placed in a vacuum desiccator for 3 days, and then stored at room temperature for 2 weeks.

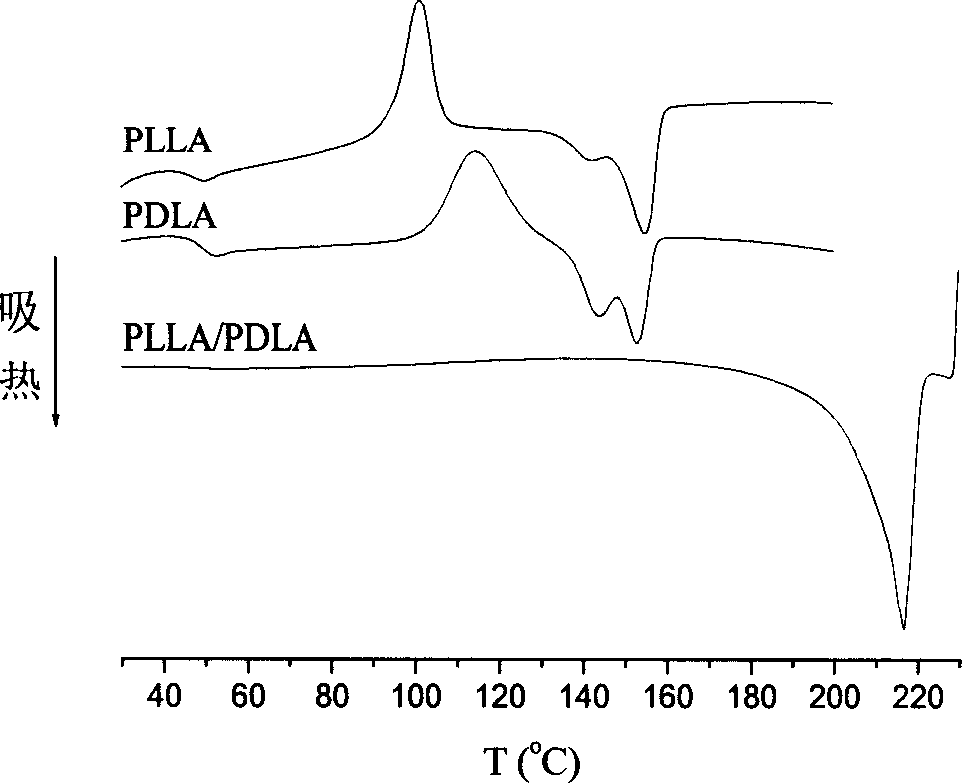

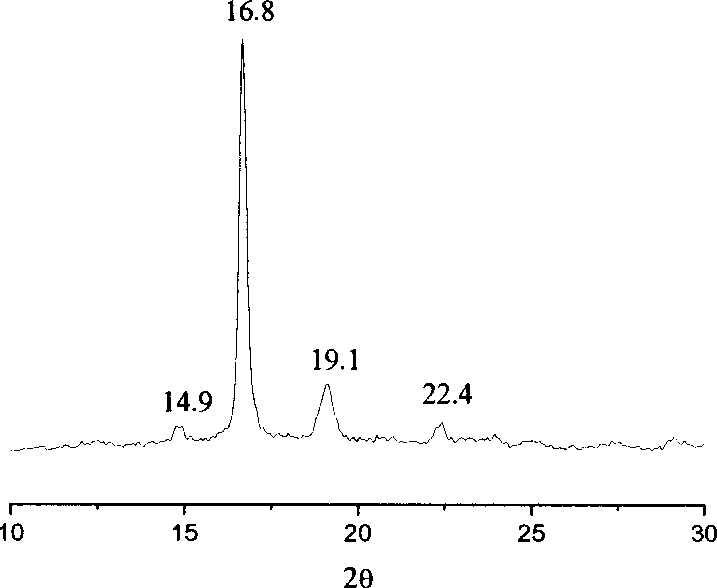

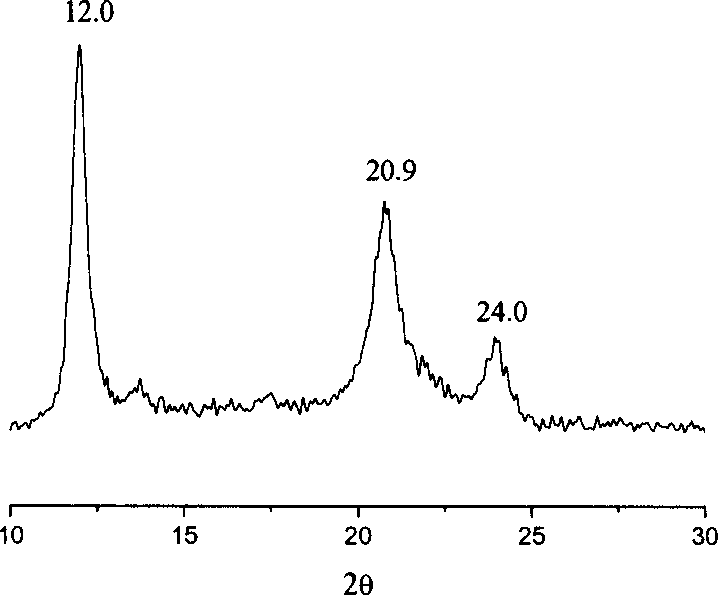

[0035] figure 1 The DSC spectrum of the polylactic acid complex and its isomers prepared for this example, it can be seen from the spectrum that the melting points of PLLA, PDLA and PLLA / PDLA complexes are 155.1, 153.2 and 216.1°C, respectively. The melting point of isomers is 60°C higher than that of the isomers. figure 2 Be the X-ray diffraction figure of present embodiment PLLA, image 3 It is the X-ray diffraction pattern of the PLLA / PDLA composite, because the X-ray diffraction pattern of PDLA is the same as that of PLLA, it is not listed here, figure 2 with image 3 Exactly the same as the X-ray diffraction pattern reported by Ikada et al. in Macromolecules 1987: 20: 904-906, demonstrating the...

Embodiment 2

[0037] Take PDLA (Mw=3.0×10 4 ) and PLLA-bisphenol A epoxy multi-block copolymer (PLLA-BisA) (Mw=1.7×10 5 ) each 1g, respectively dissolved in 20ml of dichloromethane with a concentration of 0.2g / ml, fully dissolved, poured into a jar and mixed, stirred magnetically at room temperature for 2 hours, then poured on a petri dish, and volatilized naturally at room temperature for 2 days , and then placed in a vacuum desiccator to vacuum for 3 days, and then stored at room temperature for 1 week.

[0038] Figure 7 The DSC spectrograms of the complex and its isomers prepared for this example, as can be seen from the spectrogram, the melting points of PLLA-BisA and PLLA-BisA / PDLA complexes are 137.5°C and 193.3°C respectively, and the complexes The melting point increased by 56°C. Figure 8 is the X-ray diffraction pattern of PLLA-BisA, Figure 9 is the X-ray diffraction pattern of PLLA-BisA / PDLA complex. from Figure 8 It can be seen that the PLLA-BisA X-ray diffraction patte...

Embodiment 3

[0040] Get each 5g of PDLA used in Example 1, PLLA, put into the jar that fills 50ml chloroform concentration and be 0.2g / ml and seal, after dissolving under normal temperature, magnetic force stirs 4h, makes polymer solution mix homogeneously, Then pour it on the release paper, volatilize naturally at room temperature for 3 days, put it in a vacuum oven for 3 days, and then store it at room temperature for 30 days. The complex stored for 30 days was subjected to DSC measurement, and its melting point was measured to be 215.7°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com