Biodegradable polyester composition

A technology of copolyester and composition, applied in the field of biodegradable copolyester composition, can solve the problems of insufficient heat resistance, mechanical properties, processing performance and anti-aging performance, high cost, limited application fields, etc. Production cost, excellent heat resistance, effect of widening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

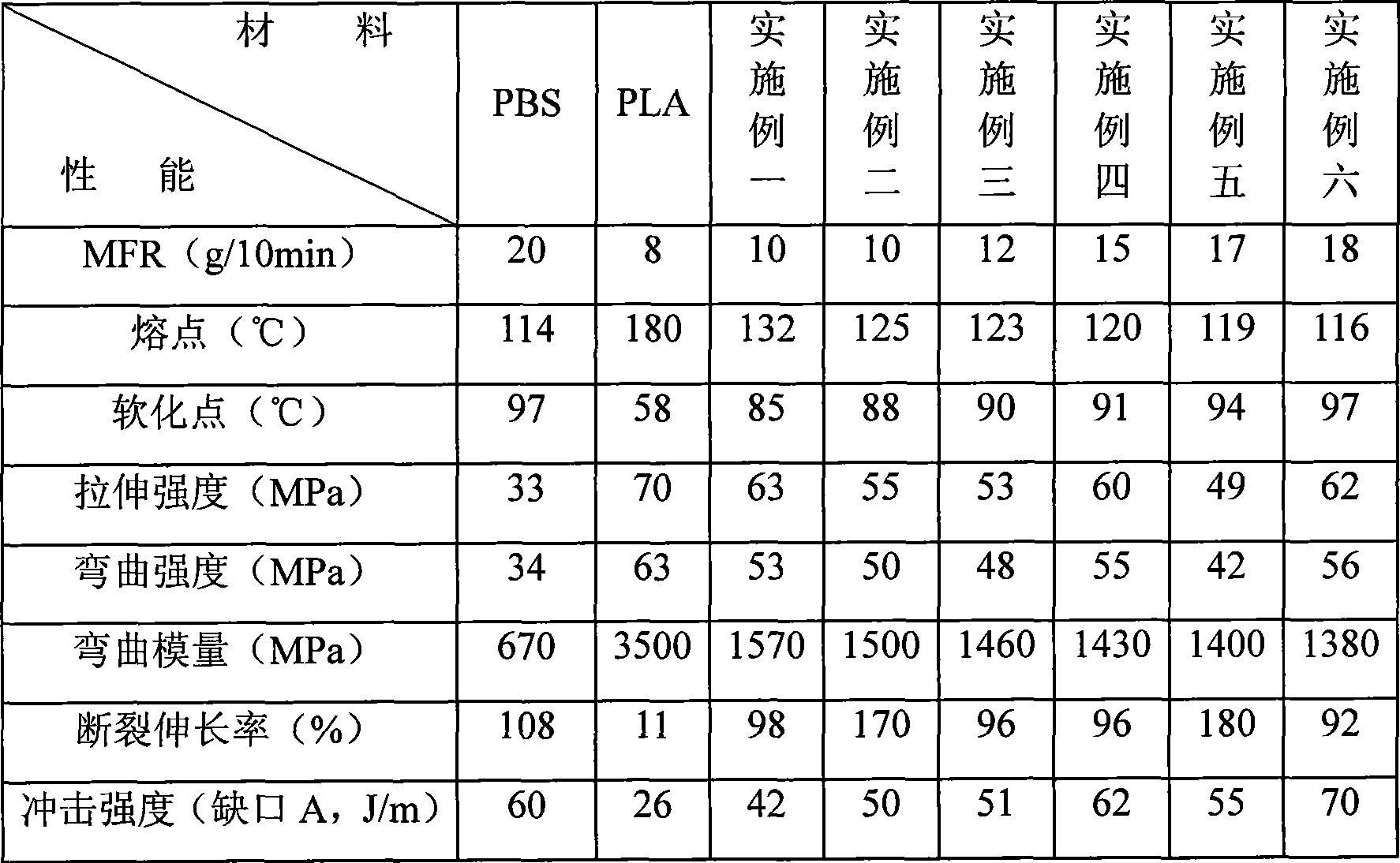

Examples

Embodiment 1

[0019] Polybutylene succinate 45Kg

[0020] Polylactic acid 50Kg

[0021] Dimethyl phthalate 2Kg

[0023] Put the dried above-mentioned materials into a high-speed mixer and mix for 30 minutes, then enter into a twin-screw extruder, and make a biodegradable copolyester composition masterbatch in the twin-screw extruder. The temperature of each section of the twin-screw extruder is as follows: first section: 170°C; second section: 150°C; third section: 150°C; fourth section: 150°C; fifth section: 150°C;

Embodiment 2

[0025] Polybutylene succinate 58Kg

[0026] Polylactic acid 35Kg

[0027] Diethyl phthalate 2Kg

[0028] Talc powder 2Kg

[0029] Nano calcium carbonate 3Kg

[0030] Put the dried above-mentioned materials into a high-speed mixer and mix for 30 minutes, then enter into a twin-screw extruder, and make a biodegradable copolyester composition masterbatch in the twin-screw extruder. The temperature of each section of the twin-screw extruder is as follows: first section: 170°C; second section: 150°C; third section: 150°C; fourth section: 150°C; fifth section: 150°C;

Embodiment 3

[0032] Polybutylene succinate 68Kg

[0033] Polylactic acid 25Kg

[0034] Dimethyl phthalate 1Kg

[0035] Diethyl phthalate 1Kg

[0036] Bamboo powder 2Kg

[0037] Nano calcium carbonate 2Kg

[0038] Nanoscale titanium silicon composite agent 1Kg

[0039] Put the dried above-mentioned materials into a high-speed mixer and mix for 30 minutes, then enter into a twin-screw extruder, and make a biodegradable copolyester composition masterbatch in the twin-screw extruder. The temperature of each section of the twin-screw extruder is as follows: first section: 170°C; second section: 150°C; third section: 150°C; fourth section: 150°C; fifth section: 150°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com