Full-biodegradation high-tenacity heat-resistant type polylactic resin and preparation method thereof

A polylactic acid resin and high toughness technology, applied in the field of fully biodegradable high toughness heat-resistant polylactic acid resin and its preparation, can solve the problems of polylactic acid degradation performance, white pollution, poor compatibility, etc., and achieve excellent processing performance , the process is simple, the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

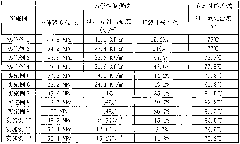

Examples

Embodiment 1

[0020] Get 80 parts by weight of polylactic acid resin with weight average molecular weight of 130,000, 20 parts by weight of polybutylene succinate with weight average molecular weight of 80,000, and 0.1 part by weight of dicumyl peroxide, 1 part by weight of glycidyl methacrylate. After the above materials are stirred evenly by a high-speed mixer, they are blended and extruded in a twin-screw extruder at an extrusion temperature of 185°C and a screw speed of 30rpm; Injection molding under injection molding conditions, and then annealing at an annealing temperature of 80° C. for 60 minutes to obtain a fully biodegradable high-toughness heat-resistant polylactic acid resin.

Embodiment 2

[0022] Get 80 parts by weight of polylactic acid resin with weight average molecular weight of 130,000, 20 parts by weight of polybutylene succinate with weight average molecular weight of 70,000, and 0.2 parts by weight of dicumyl peroxide, 1 part by weight of glycidyl methacrylate. After the above materials are stirred evenly by a high-speed mixer, they are blended and extruded in a twin-screw extruder at an extrusion temperature of 185°C and a screw speed of 20rpm; the extruded resin is molded at an injection temperature of 180°C and an injection pressure of 10MPa After injection molding, it is annealed at an annealing temperature of 80° C. for 60 minutes to obtain a fully biodegradable high-toughness heat-resistant polylactic acid resin.

Embodiment 3

[0024] Get 80 parts by weight of polylactic acid resin with weight average molecular weight of 130,000, 20 parts by weight of polybutylene succinate with weight average molecular weight of 80,000, and 0.25 parts by weight of dicumyl peroxide, 2.5 parts by weight of glycidyl methacrylate. After the above materials are stirred evenly by a high-speed mixer, they are blended and extruded in a twin-screw extruder at an extrusion temperature of 185°C and a screw speed of 20rpm; the extruded resin is molded at an injection temperature of 180°C and an injection pressure of 10MPa After injection molding, it is annealed at an annealing temperature of 80° C. for 60 minutes to obtain a fully biodegradable high-toughness heat-resistant polylactic acid resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com