Continuously-produced full-degradable starch-based plastic alloy and preparation method thereof

A technology for starch-based plastics and alloys, which is applied in the field of continuous production of fully degradable starch-based plastic alloys and their preparation, can solve the problems of poor toughness, long production cycle and high cost of all-starch plastics, and achieves good processing formability, mechanical properties and mechanical properties. Excellent performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of starch-based plastic alloy of the present invention comprises the following steps:

[0055] i) adding starch, plasticizer and some processing aids to a high-speed mixer and mixing uniformly to obtain the first mixture;

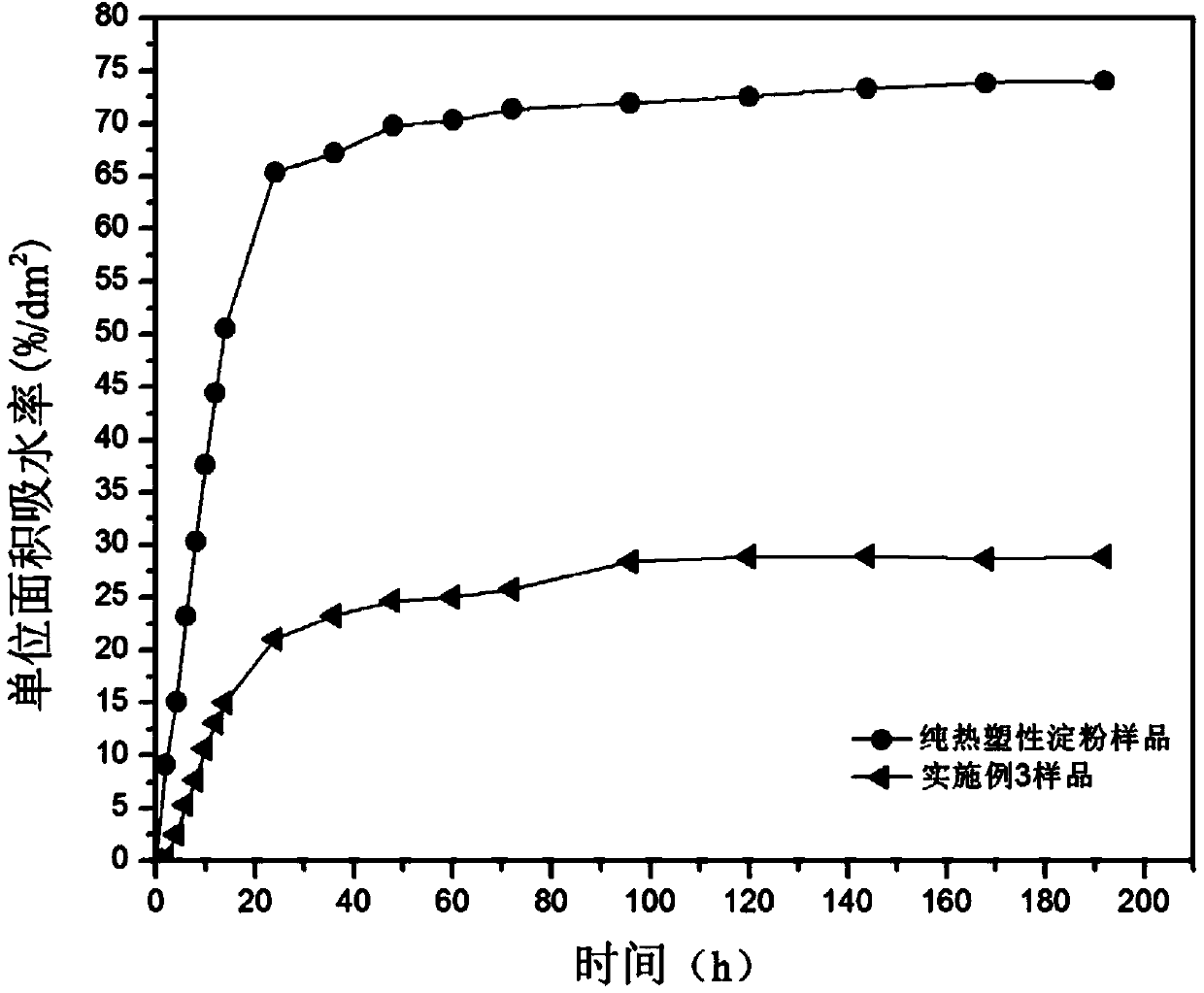

[0056] ii) The first mixture is sealed and left to stand for 24 to 48 hours, extruded through a twin-screw extruder, cooled, granulated, and dried to obtain thermoplastic starch granules;

[0057] iii) adding the thermoplastic starch granules, polybutylene succinate, polylactic acid, compatibilizer and remaining processing aids to a high-speed mixer and mixing uniformly to obtain a second mixture;

[0058] iv) adding the second mixture into a twin-screw extruder and extruding to obtain the starch-based plastic alloy.

[0059] The parts by weight of said starch, plasticizer, polybutylene succinate, polylactic acid, compatibilizer, processing aid are as described in claim 1. The weight of the processing aid is the sum of the we...

Embodiment 1

[0077] Preparation of starch-based plastic alloys

[0078] The first step, preparation of thermoplastic starch granules

[0079] First 100 parts by weight of potato starch, 20 parts by weight of glycerol, 5 parts by weight of water, 1 part by weight of stearic acid, 2 parts by weight of liquid paraffin, and 1 part by weight of antioxidant 1010 are added to the high-speed mixer, and the temperature is set to 80°C, mix at high speed for 5 minutes, cool down and unload.

[0080] Put the above materials into a twin-screw extruder after standing for 24 hours, extrude and granulate at a temperature of 150-120° C. and a rotation speed of 200 rpm to obtain thermoplastic starch granules.

[0081] The second step, the preparation of starch-based plastic alloy

[0082] 60 parts by weight of the thermoplastic starch granules obtained in the first step, 30 parts by weight of polybutylene succinate, and 10 parts by weight of polylactic acid were vacuum-dried at 80°C for 24 hours, added to...

Embodiment 2-5

[0087] The steps of Examples 2-5 are the same as those in Example 1, except that the raw materials, raw material proportions, and processing conditions are different, as shown in Table 1 below.

[0088] The experimental condition of table 1 embodiment 2-5

[0089]

[0090]

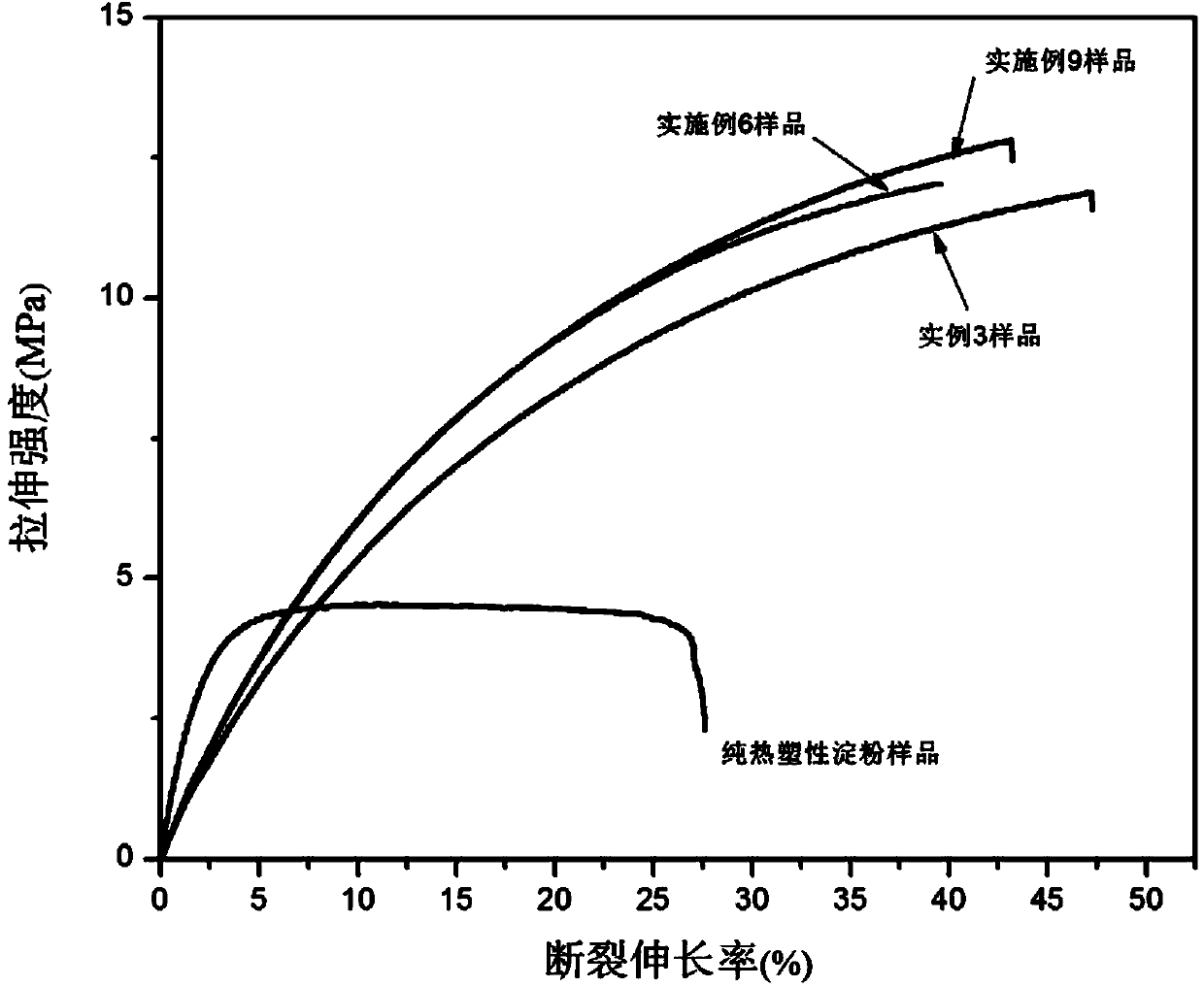

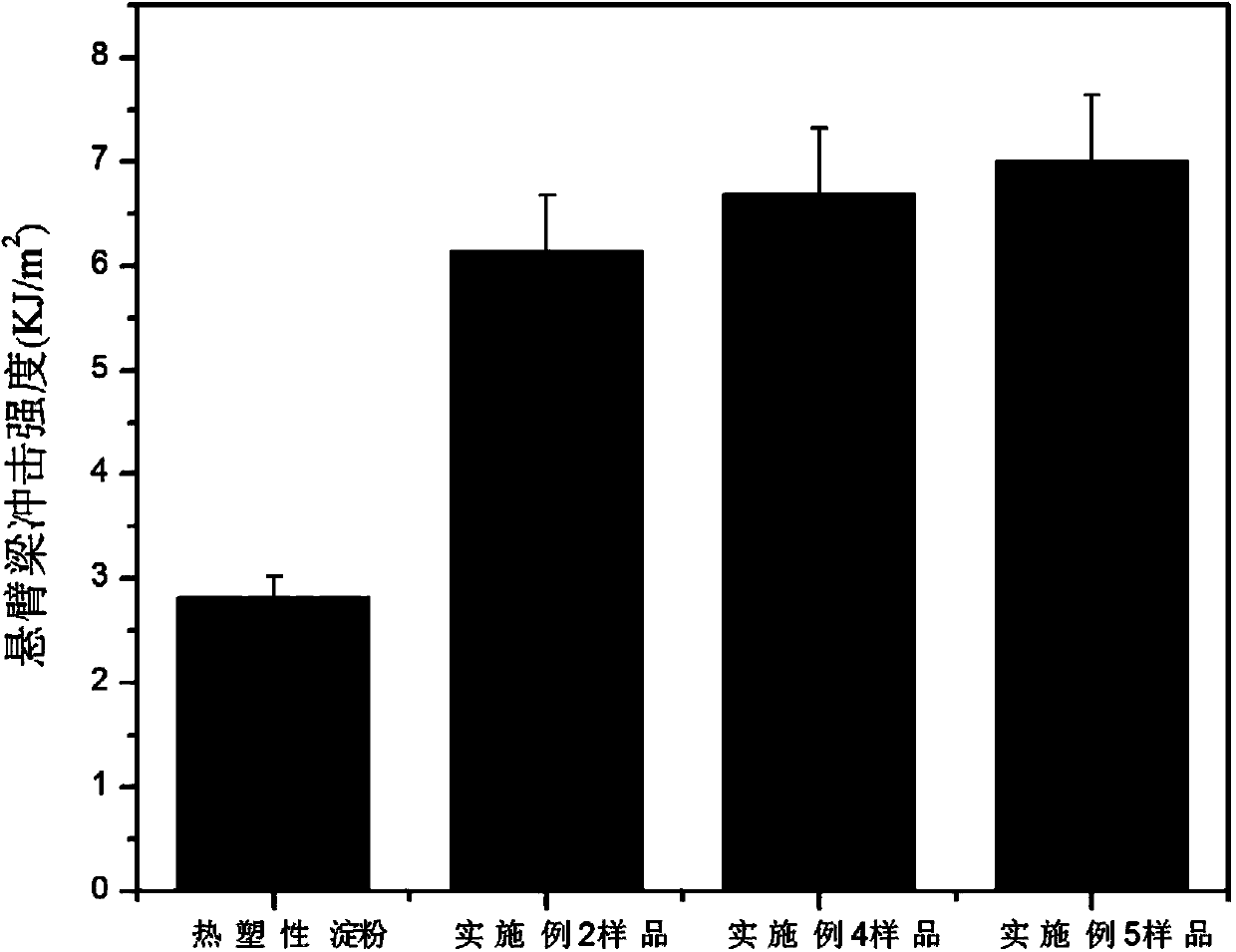

[0091] The properties of the starch-based plastic alloys prepared in Examples 2-5 are shown in Table 2.

[0092] Table 2 The physical properties of the starch-based plastic alloys prepared in Examples 2-5

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com