Novel liquid air-separating device and novel liquid air-separating process

An air separation plant and liquid technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of poor variable load capacity, difficult product purity nitrogen purity control, high energy consumption, increase oxygen production, and achieve continuity Production, the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

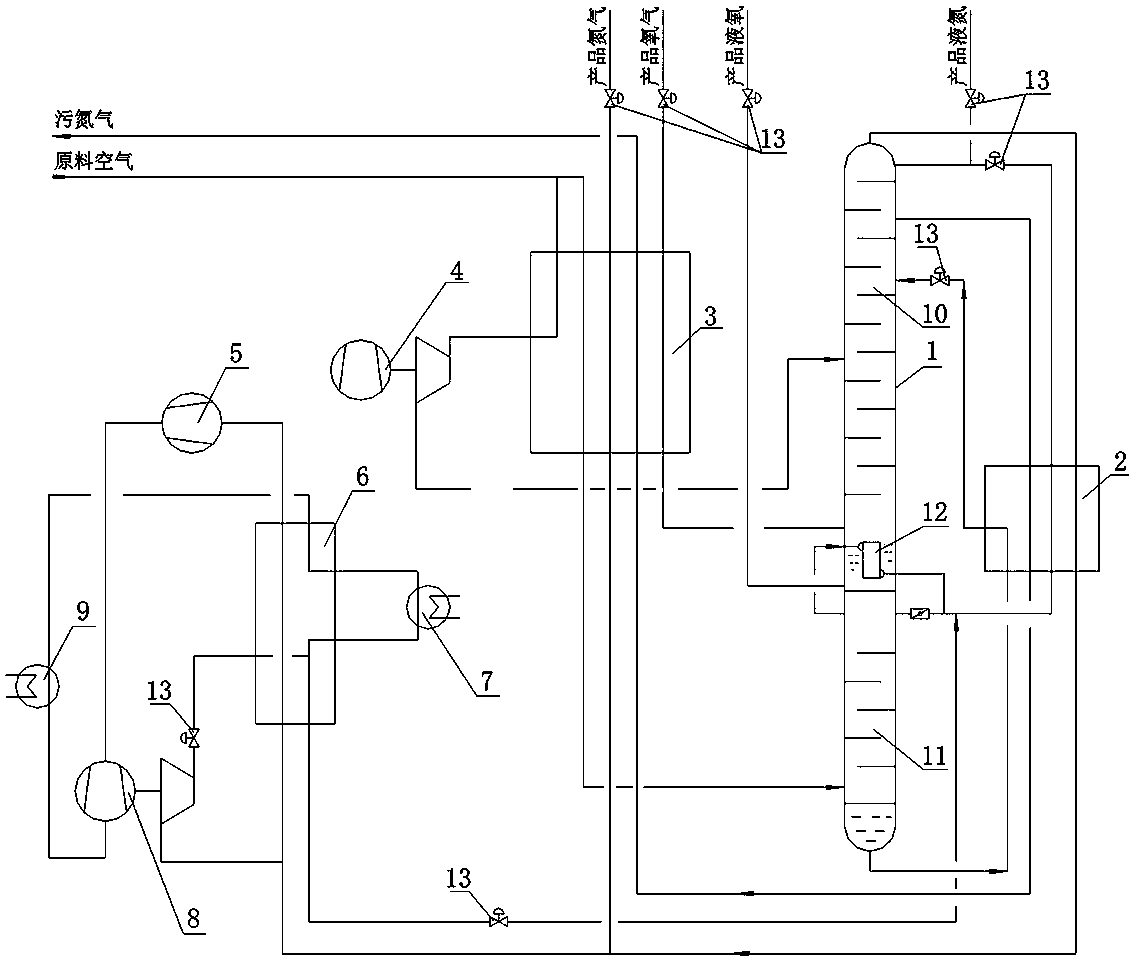

[0018] Such as figure 1 As shown, the new liquid air separation plant includes a rectification tower 1, a subcooler 2, a main heat exchanger 3, an expander 4, a circulating nitrogen compressor 5, a liquefaction heat exchanger 6, a low-temperature air-conditioning unit 7, a booster Expander 8, supercharger aftercooler 9, rectification tower 1 comprises upper tower 10, lower tower 11 and the main condensing evaporator 12 that is arranged between upper tower 10 and lower tower 11, and dry air intake pipe is divided into two One way of the dry air inlet pipe is connected with the feed air passage A of the main heat exchanger 3 and the air inlet at the lower part of the lower tower 11 in turn, and the other road of the dry air inlet pipe is connected with the feed air passage B of the main heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com