Synthesis method of lithium extraction adsorbent

A synthesis method and lithium adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, titanium compounds, etc., can solve the problems of difficult control of mass transfer in solid phase reactions, difficulty in ensuring uniform mixing, etc., and achieve structural stability and reduction Small agglomeration, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Dissolve 6.1835g of lithium hydroxide monohydrate in 100ml of an aqueous solution containing 5% cetyltrimethylammonium bromide, and add 4.0338g to it under stirring (Li / Ti molar ratio is 2.80:1) Anatase-type titanium dioxide, continue to stir for 24h, the obtained slurry is spray-dried at a feed rate of 5ml / min under stirring, and the spray temperature is 120°C to obtain a solid powder;

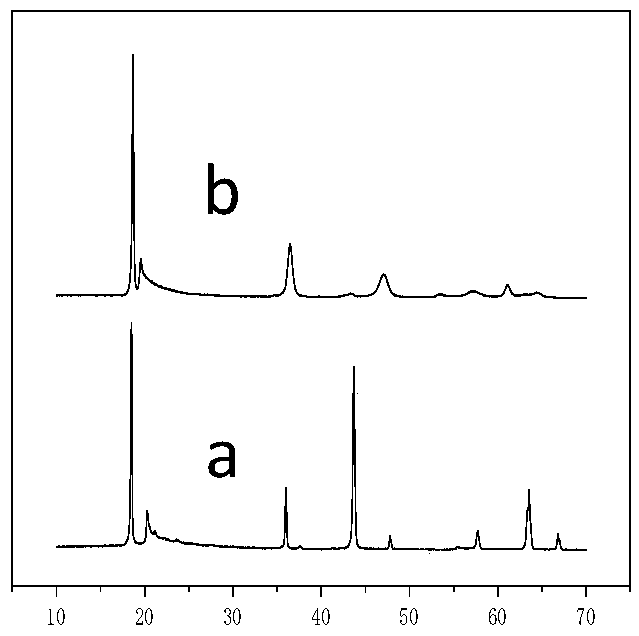

[0029] 2. The obtained solid powder was calcined in a muffle furnace at a temperature of 5°C / min to 700°C for 72h to obtain the metatitanic acid lithium ion sieve precursor Li 2 TiO 3 ;

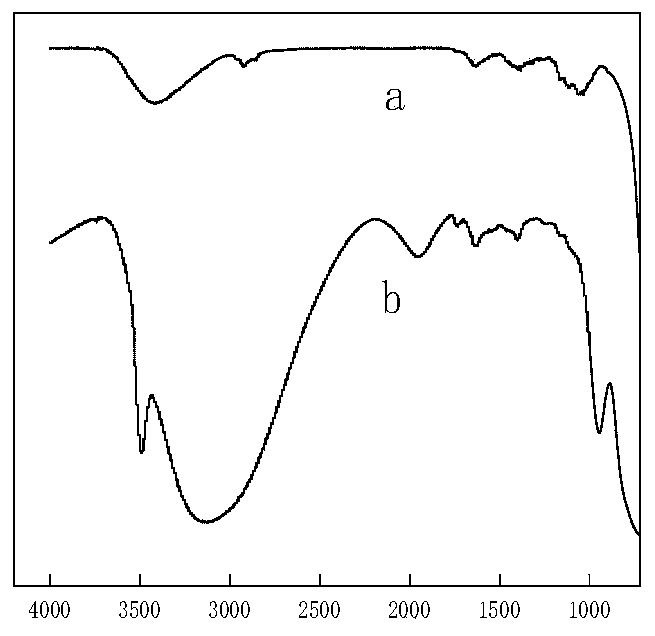

[0030] 3. Put the precursor body into 2 TiO 3 Add the powder into 0.3mol / L hydrochloric acid solution (solid-to-liquid ratio is 6g / L), magnetically stir at 50°C for 6h to remove lithium, filter, wash, and dry to obtain the metatitanic acid lithium ion sieve adsorbent H 2 TiO 3 ;

[0031] 4. Add the ion sieve to a solution with a pH of 10 and a lithium concentration of 500 mg / L, and magnetical...

Embodiment 2

[0034] 1. Dissolve 8.2440g of lithium acetate dihydrate in 80ml of absolute ethanol, add 4.0338g of rutile titanium dioxide (Li / Ti molar ratio is 1.60:1) to it under stirring, continue stirring for 0.5h, and the resulting slurry is stirred In the state, the feed rate is 3ml / min, and the inlet air temperature is 110°C for flash drying to obtain a solid powder;

[0035] 2. The obtained solid powder was calcined in a muffle furnace at a rate of 1°C / min to 550°C for 12 hours to obtain the metatitanic acid lithium ion sieve precursor Li 2 TiO 3 ;

[0036] 3. Put the precursor body into 2 TiO 3 Add the powder into 0.01mol / L hydrochloric acid solution (solid-to-liquid ratio is 0.5g / L), magnetically stir at 90°C for 8 hours to remove lithium, filter, wash, and dry to obtain the metatitanic acid lithium ion sieve adsorbent H 2 TiO 3 ;

[0037] 4. Add the ion sieve to a solution with a pH of 11 and a lithium concentration of 1 g / L, and magnetically stir at 55°C for 12 hours, and t...

Embodiment 3

[0039] 1. Dissolve 4.4794g of lithium chloride in 800ml of an aqueous solution containing 20% polyvinylpyrrolidone, add 4.0338g of rutile titanium dioxide (Li / Ti molar ratio is 2.05:1) to it under stirring, and continue stirring for 48h to obtain Slurry is under stirring state with the feed rate of 20ml / min, and vacuum degree is 60kPa, and shaft speed is 10rpm and carries out vacuum drying with steam heating, obtains solid powder;

[0040] 2. The obtained powder was calcined in a muffle furnace at a rate of 5°C / min to 800°C for 9 hours to obtain the metatitanate lithium ion sieve precursor Li 2 TiO 3 ;

[0041] 3. Put the precursor body into 2 TiO 3 Add the powder into 1mol / L nitric acid solution (solid-to-liquid ratio is 50g / L), stir magnetically at 45°C for 0.15h to delithiate, filter, wash, and dry to obtain the metatitanic acid lithium ion sieve adsorbent H 2 TiO 3 ;

[0042] 4. Add the ion sieve to a solution with a pH of 10 and a lithium concentration of 200 mg / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com