Preparation method of rutile type calcining seeds with high activity and high stability

A calcined seed crystal, high stability technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of short feeding time, increased production cost, inaccurate parameter control, etc., and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The raw materials are prepared according to the alkali-titanium ratio of 1.3:1. Preheat the metatitanic acid to 100°C, preheat the lye with 30% concentration to 125°C, add the metatitanic acid into the lye slowly and uniformly, the feeding time is 30min, and then take 1°C / min to raise the temperature to Boil and keep in a slightly boiling state, and continue to react for 120 minutes to prepare ortho-titanate; add water to dilute to 120g / L, then cool, wash with 40°C water and filter to obtain ortho-titanate slurry. According to the acid-titanium ratio of 0.35:1, hydrochloric acid with a concentration of 30% (weight%) was added to the ortho-titanic acid slurry, the pH value was adjusted to 3.0, and the temperature was raised to 60°C at a rate of 1°C / min and kept warm. Then add 30% hydrochloric acid to adjust the pH value to 1.0, heat up to boiling at a rate of 1°C / min, mature for 75 minutes, add water to quench, and obtain high-activity and high-stability rutile calcined ...

Embodiment 2

[0017] The raw materials were prepared according to the alkali-titanium ratio of 1.4:1. Preheat the metatitanic acid to 90°C, preheat the lye with 30% concentration to 115°C, add the metatitanic acid into the lye slowly and uniformly, the feeding time is 35min, and then take 1°C / min to raise the temperature to Boil and keep in a slightly boiling state, and continue to react for 120 minutes to prepare ortho-titanate; add water to dilute to 120g / L, then cool, wash with 40°C water and filter to obtain ortho-titanate slurry. According to the acid-titanium ratio of 0.40:1, hydrochloric acid with a concentration of 32% (weight%) was added to the ortho-titanic acid slurry, the pH value was adjusted to 3.1, and the temperature was raised to 60°C at a rate of 1°C / min and kept warm. Then add 32% concentration of hydrochloric acid, adjust the pH to 1.0, heat up to boiling at a rate of 1°C / min, mature for 80 minutes, add water to quench, and obtain high-activity and high-stability rutile ...

Embodiment 3

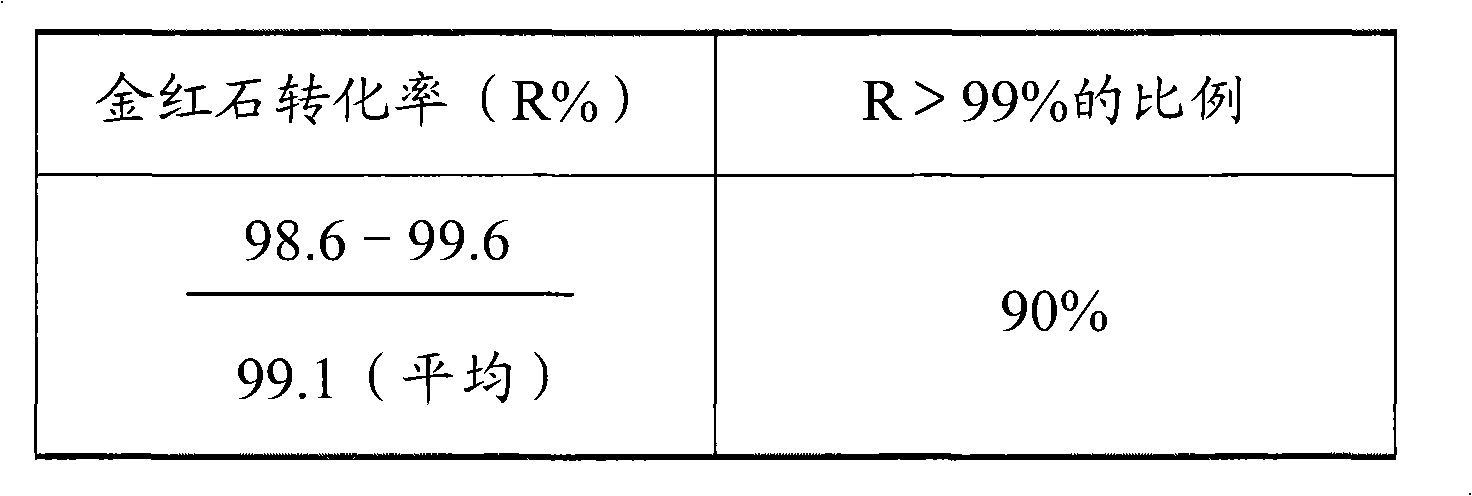

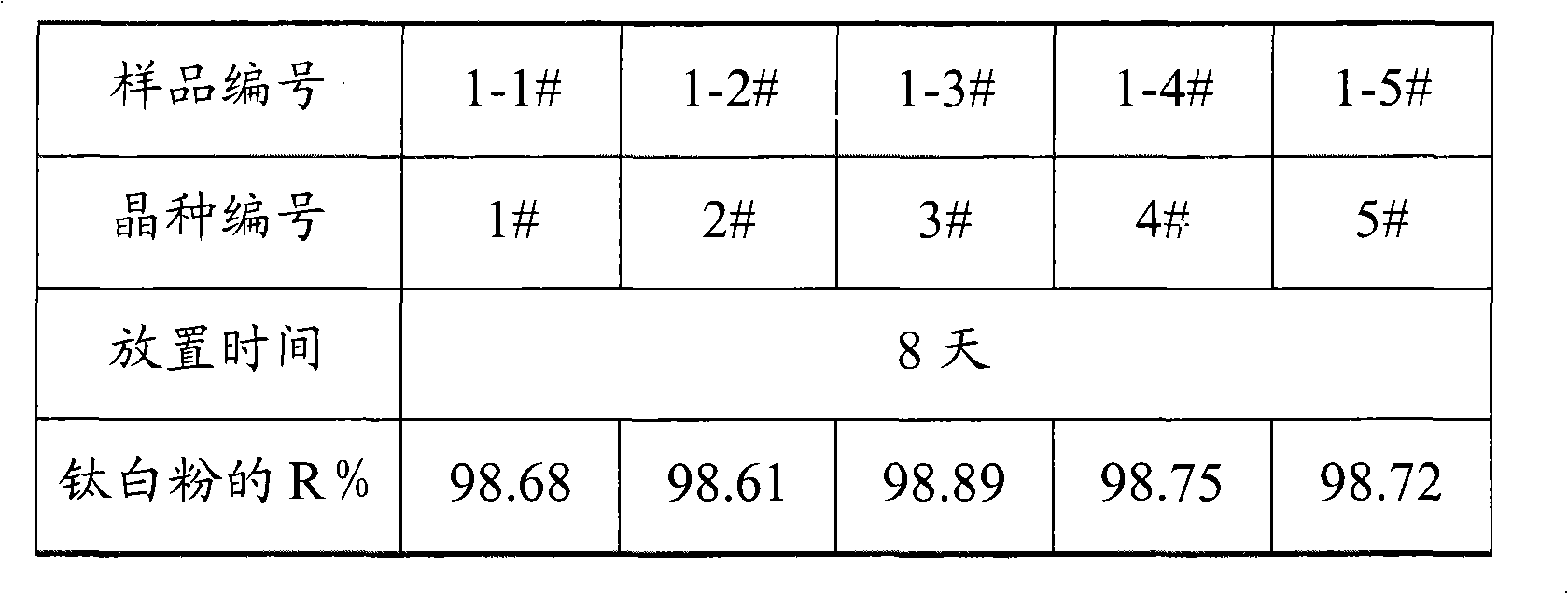

[0019] The raw materials are prepared according to the alkali-titanium ratio of 1.5:1. Preheat metatitanic acid to 85°C, preheat 40% lye to 110°C, add metatitanic acid to the lye slowly and uniformly, the feeding time is 45min, and then take 1°C / min to heat up to Boil and keep in a slightly boiling state, and continue to react for 120 minutes to prepare ortho-titanate; add water to dilute to 120g / L, then cool, wash with 45°C water and filter to obtain ortho-titanate slurry. According to the acid-titanium ratio of 0.45:1, hydrochloric acid with a concentration of 34% (weight%) was added to the ortho-titanic acid slurry, the pH value was adjusted to 2.9, and the temperature was raised to 60°C at a rate of 1°C / min and kept warm. Then add 34% hydrochloric acid, adjust the pH value to 1.0, heat up to boiling at a rate of 1°C / min, mature for 85 minutes, add water to quench, and obtain high-activity and high-stability rutile calcined seed crystals. The rutile conversion rate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com