Efficient grinding machine special for sliding blocks

A special grinding machine and slider technology, which is applied to grinding machines, machine tools suitable for grinding workpiece planes, and parts of grinding machine tools, etc., can solve the problems of inability to guarantee the surface roughness of finished products, inability to guarantee accuracy, and low processing efficiency. Achieve the effect of saving one-time investment, saving labor costs and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The orientation words such as front, back, left, right, up, and down involved in the present invention are all set to clearly express the technical solution, and do not limit the scope of protection of the invention.

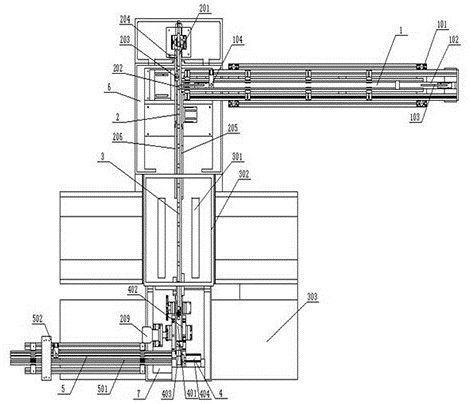

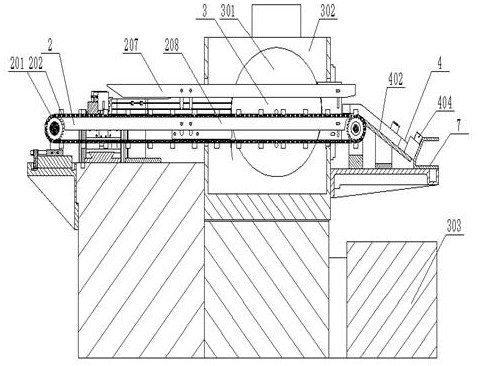

[0044] Such as figure 1 , figure 2As shown, the high-efficiency slider special grinding machine of the present invention includes a rodless cylinder-driven feeding system 1, a feeding system 2, a grinding system 3, a pushing system 4 and a feeding system 5, which are respectively used to complete the feeding process and the feeding process , processing procedure, pushing procedure and unloading procedure. The rodless cylinder driven feeding system 1 includes a feed truss 101, the upper side of the feed truss 101 is fixed with a rodless cylinder 102, and the feed truss 101 is used to support and fix the rodless cylinder 102, A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com