Digital assembling and manufacturing method for tailor-welded pipeline

A manufacturing method and pipeline technology, applied in the direction of manufacturing tools, manufacturing computing systems, comprehensive factory control, etc., can solve the problems of low pipelines, achieve the effects of large space, elimination of waiting time for assembly, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

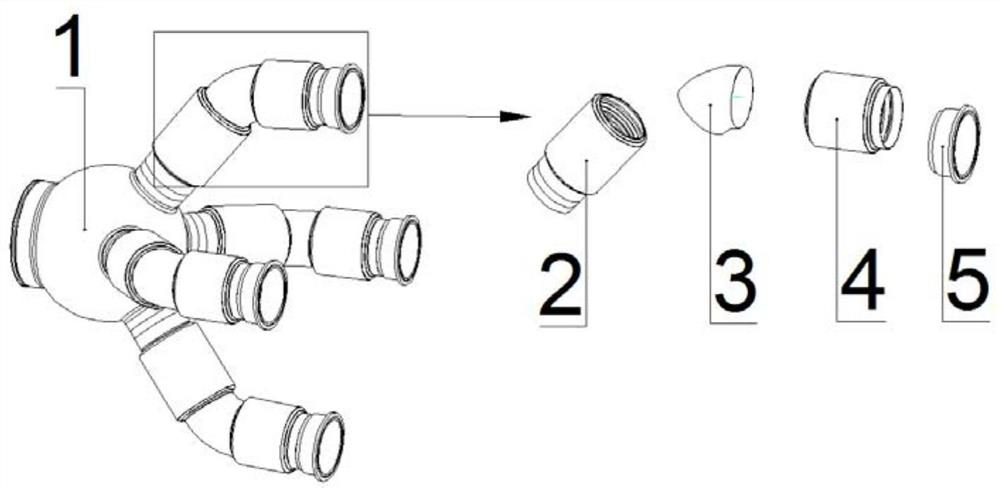

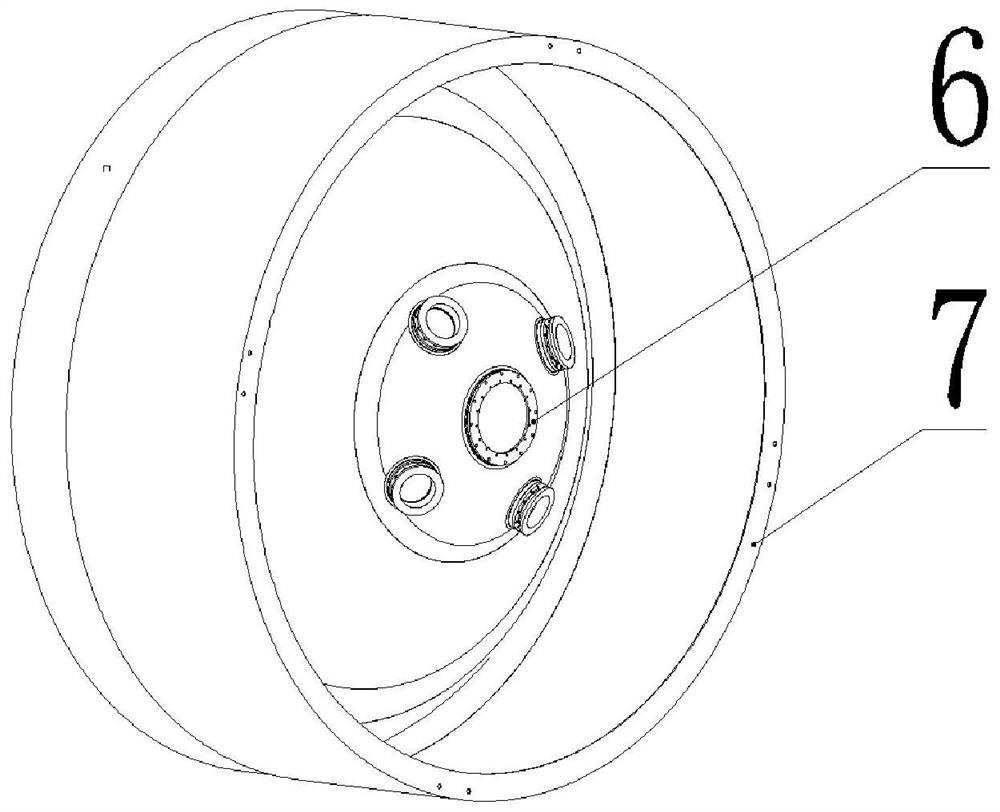

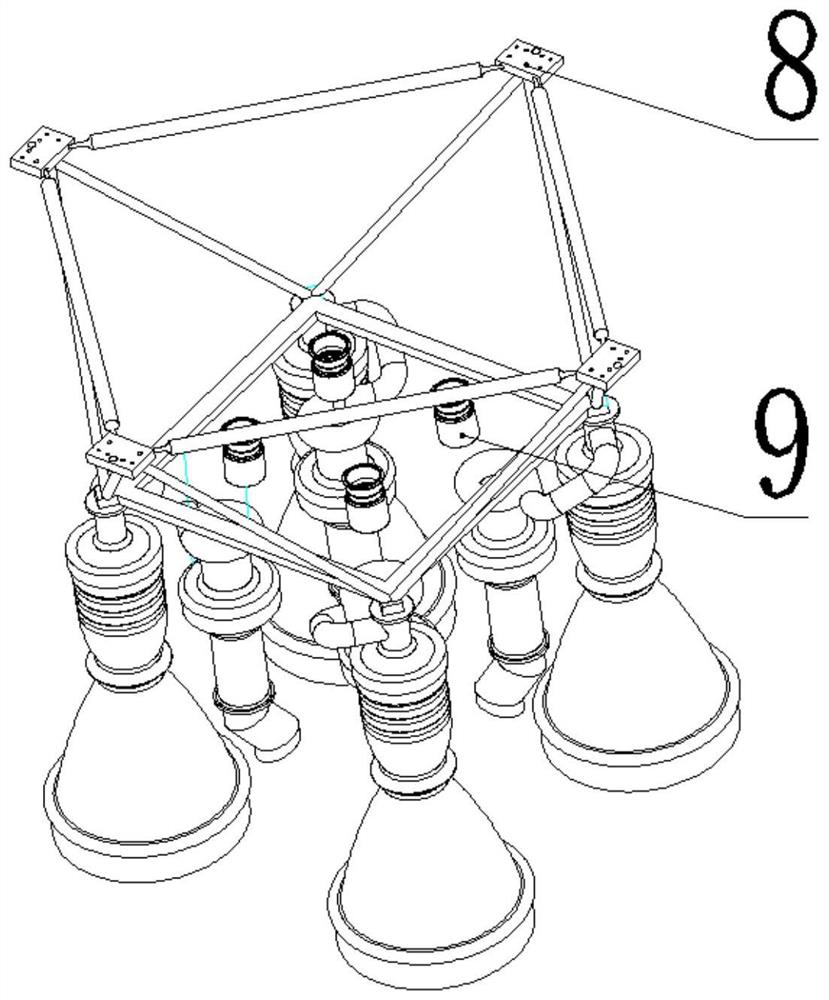

[0028] The tailor-welded pipeline digital assembly manufacturing process provided by the present invention can be summarized into three main steps of "measurement", "modeling" and "manufacturing". That is, the basic data of digital sampling is obtained by measurement, the calculation of the virtual boundary conditions of the pipeline is completed by modeling, and the manufacture of parts is completed based on the model data.

[0029] Specifically, after the parts, boxes, engines and other products are complete, and the assembly workshop has the measurement conditions, the laser tracker is used to complete the measurement of the key geometric features of the boundary conditions at both ends of the pipeline, and the three-dimensional measurement in SA (Spatial Analyzer) In the software, the establishment of the coordinate system is completed according to the obtained data, so as to realize the description of the key feature space geometric information at both ends of the pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com