Dielectric-capacitance testing method of deformation degree of transformer winding

A transformer coil, deformation degree technology, applied in the direction of electric/magnetic solid deformation measurement, instruments, measuring devices, etc., can solve the problems of inability to accurately determine the coil deformation position, field wiring interference, etc., to ensure normal and safe operation and improve work. The effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: overall introduction method

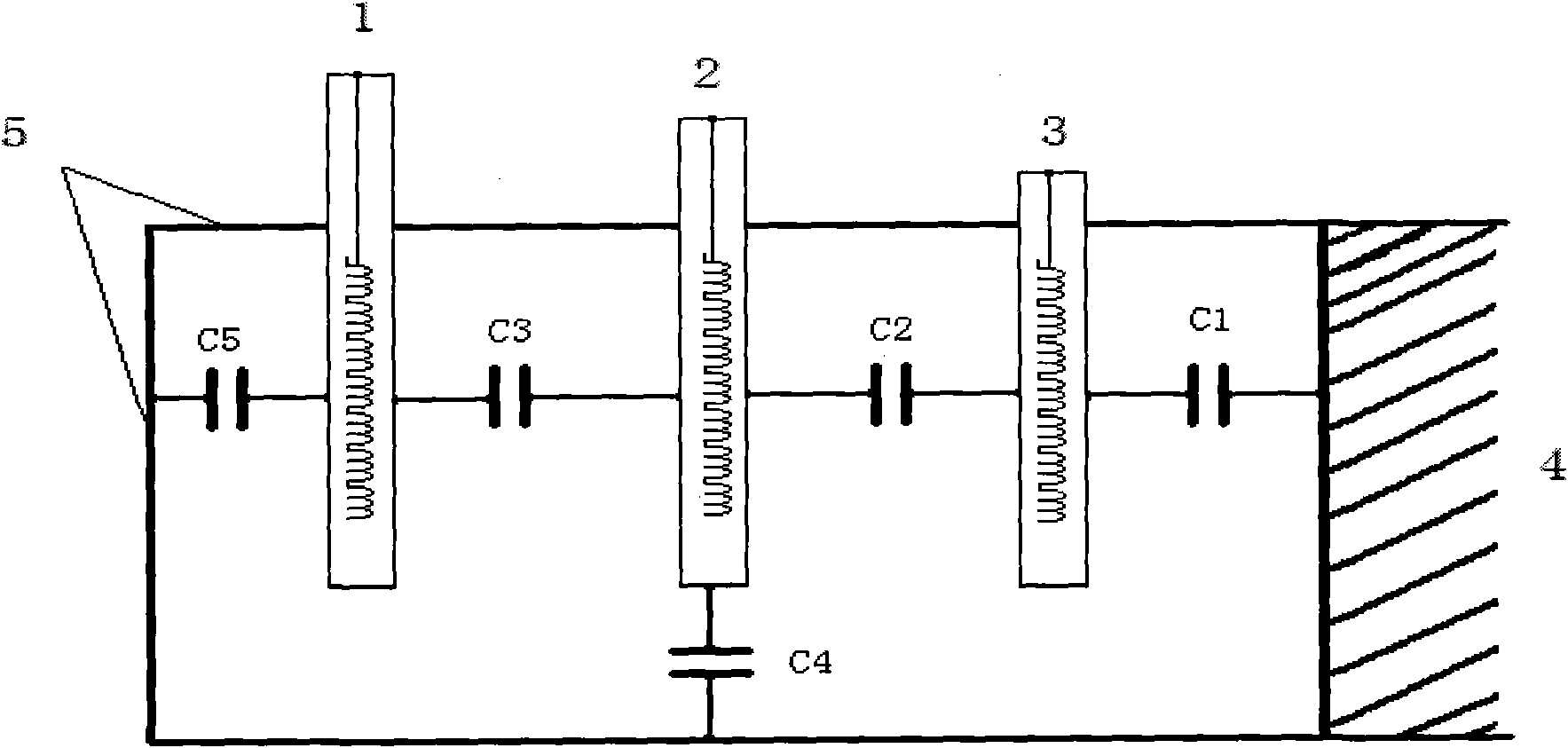

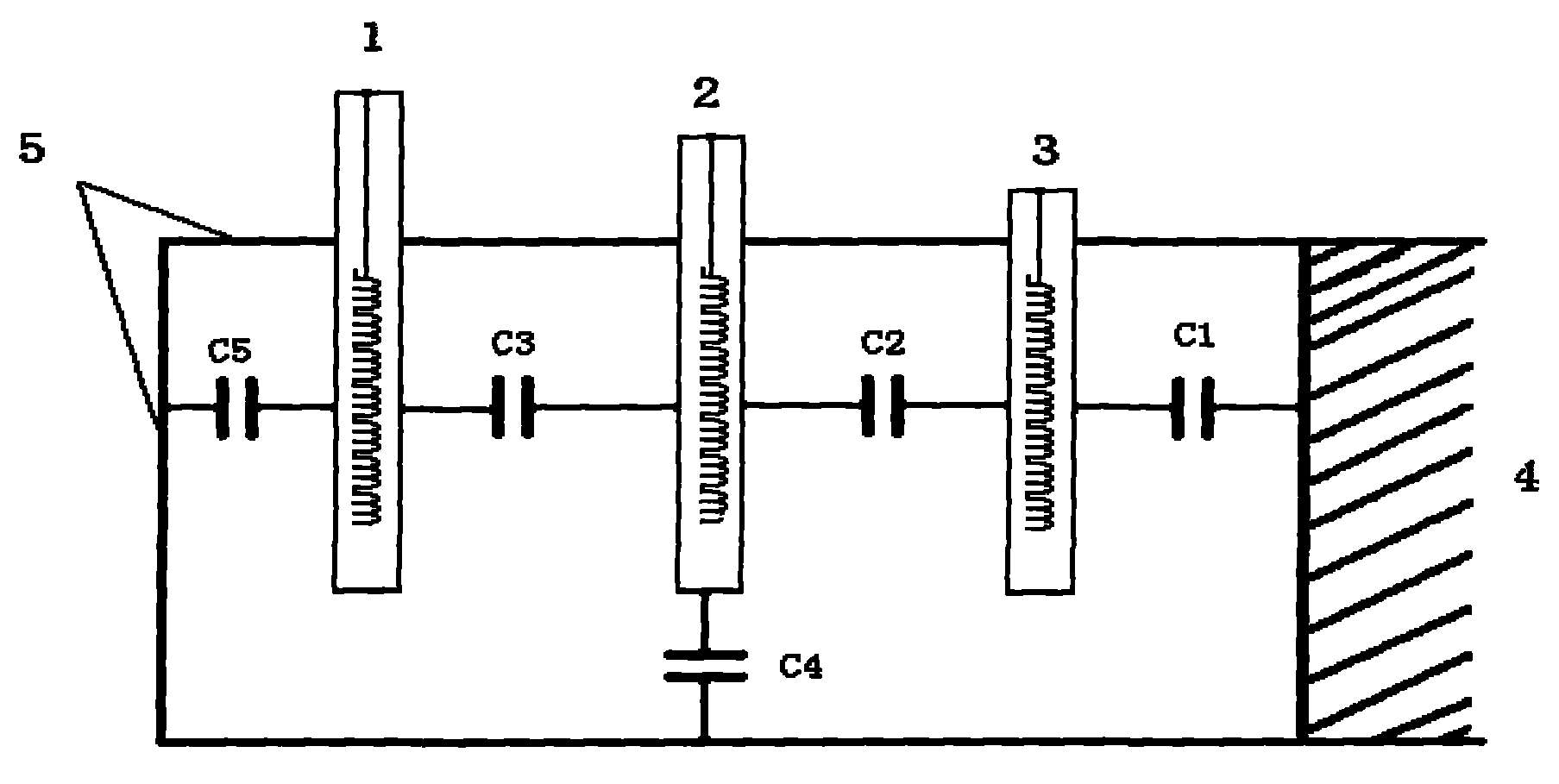

[0029] Test wiring: The measuring instrument adopts the high-voltage dielectric loss meter based on the principle of Xilin bridge. And ground dielectric loss and capacitance measurement. Through the test data of the five dielectric losses and capacitances of the high, medium and low windings of the transformer, the capacitance of the low voltage winding to ground; the capacitance between the medium and low voltage windings; the capacitance between the high and medium voltage windings; The capacitance of the voltage winding to the ground; the capacitance and dielectric loss of the high voltage winding to the ground. Through these five dielectric loss and capacitance changes from the factory value, the degree of coil deformation of the voltage level of the transformer coil can be judged. The capacitance and dielectric loss of each part of the test wiring and the tested transformer are shown in Table 1:

[0030] Table 1 Test w...

Embodiment 2

[0040] Embodiment 2: interphase capacity method

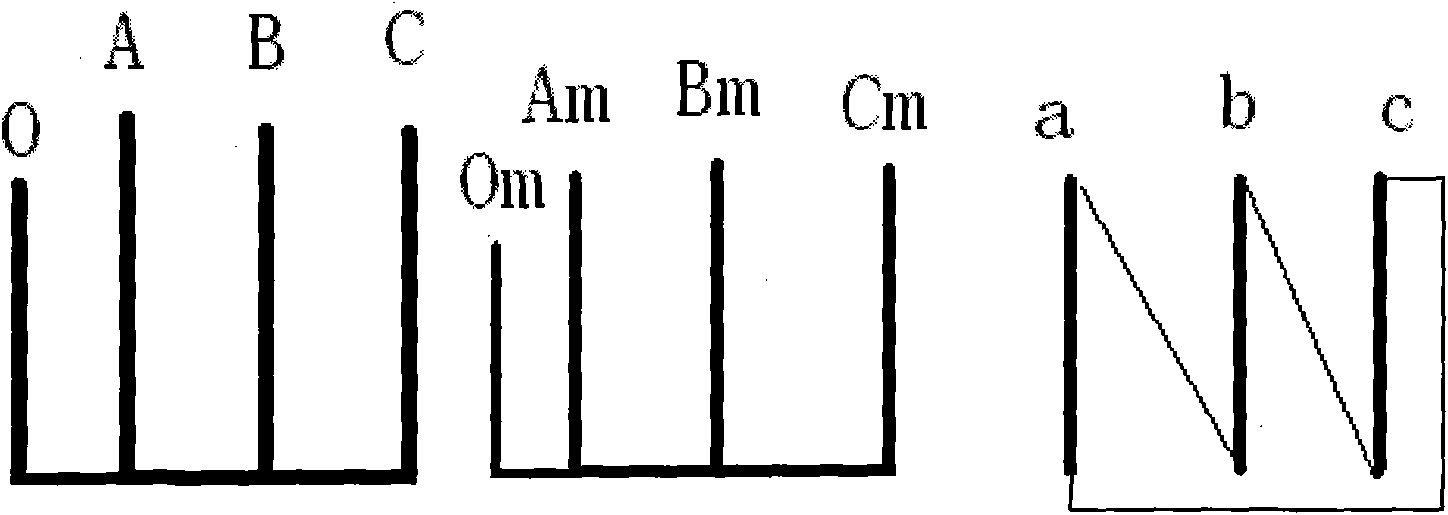

[0041] In order to accurately detect the degree of deformation of which phase coil of the transformer, the phase-to-phase dielectric loss and capacitance of the winding are tested separately, that is, the high-voltage windings A, B, and C are respectively measured relative to the medium-voltage windings Am, Bm, and Cm phases, and the medium-voltage The windings Am, Bm, and Cm are relatively low-voltage windings a, b, and c-phase, and the dielectric loss and capacitance of the low-voltage winding to the iron core. Most of the 110-220kV transformers operating in the domestic power grid are connected at points Yn, yn0, and d11. The voltage levels of high-voltage windings are 110kV and 220kV, the voltage levels of medium-voltage windings are 35kV and 110kV, and the voltage levels of low-voltage windings are 10kV and 35kV. two kinds. The low-voltage winding connection method is to connect the 11-point connection method inside the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com