Coat-removing device for coat-removing oil-fried peanut kernels based on bionic kneading

A technique for frying peanuts and peeling equipment, which is applied in the direction of shelling, pod removal, and separating solids from solids with airflow, which can solve the problems of difficult separation of peanut skins, unhygienic, and low efficiency. Achieve the effect of saving manufacturing cost, reducing waste and stabilizing conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

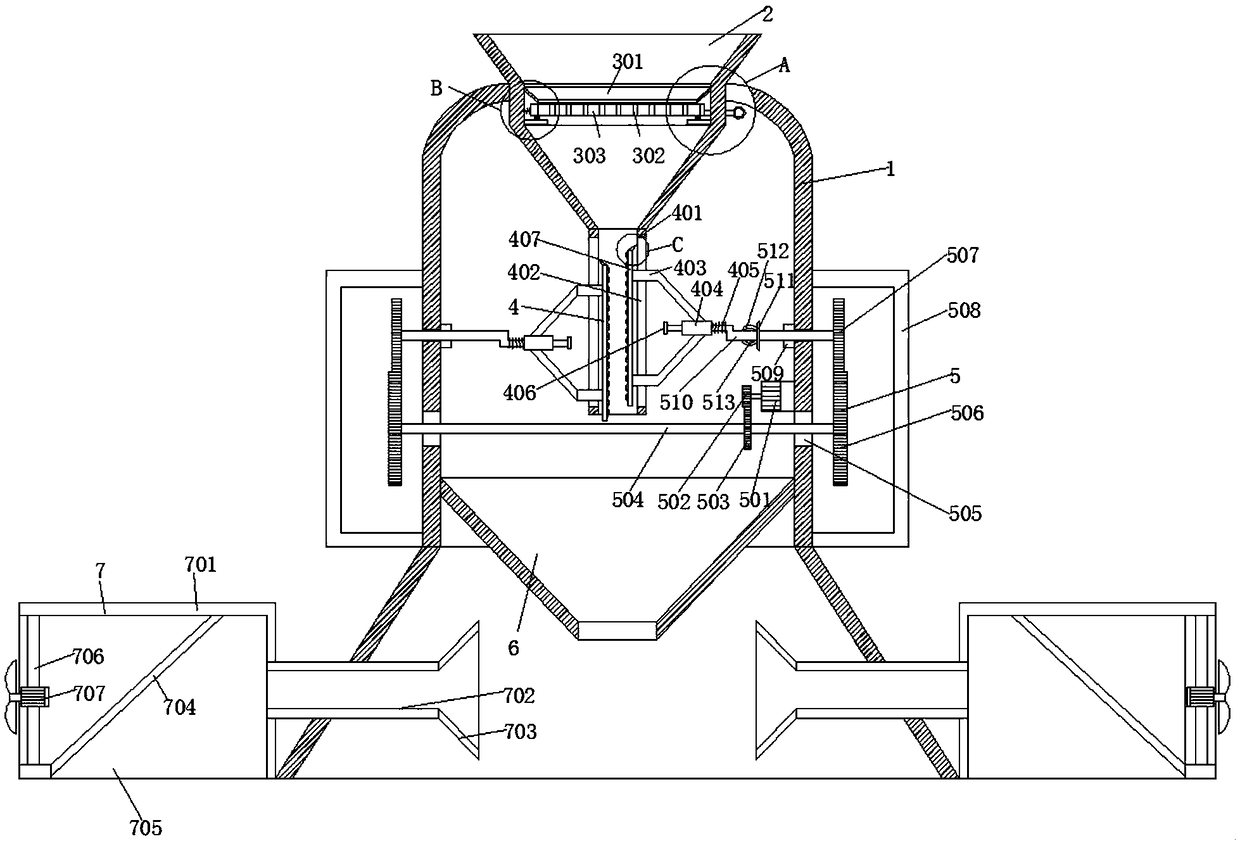

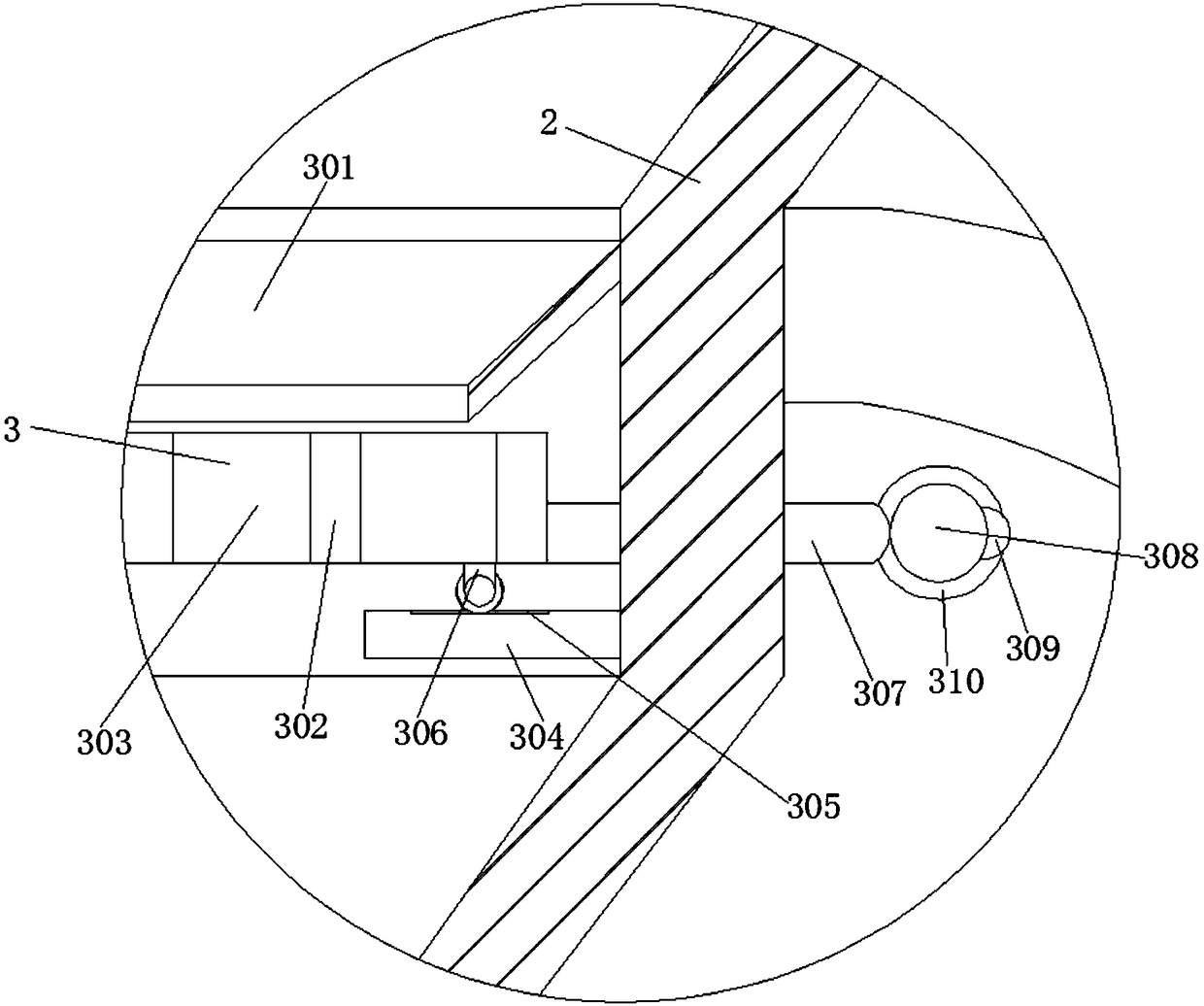

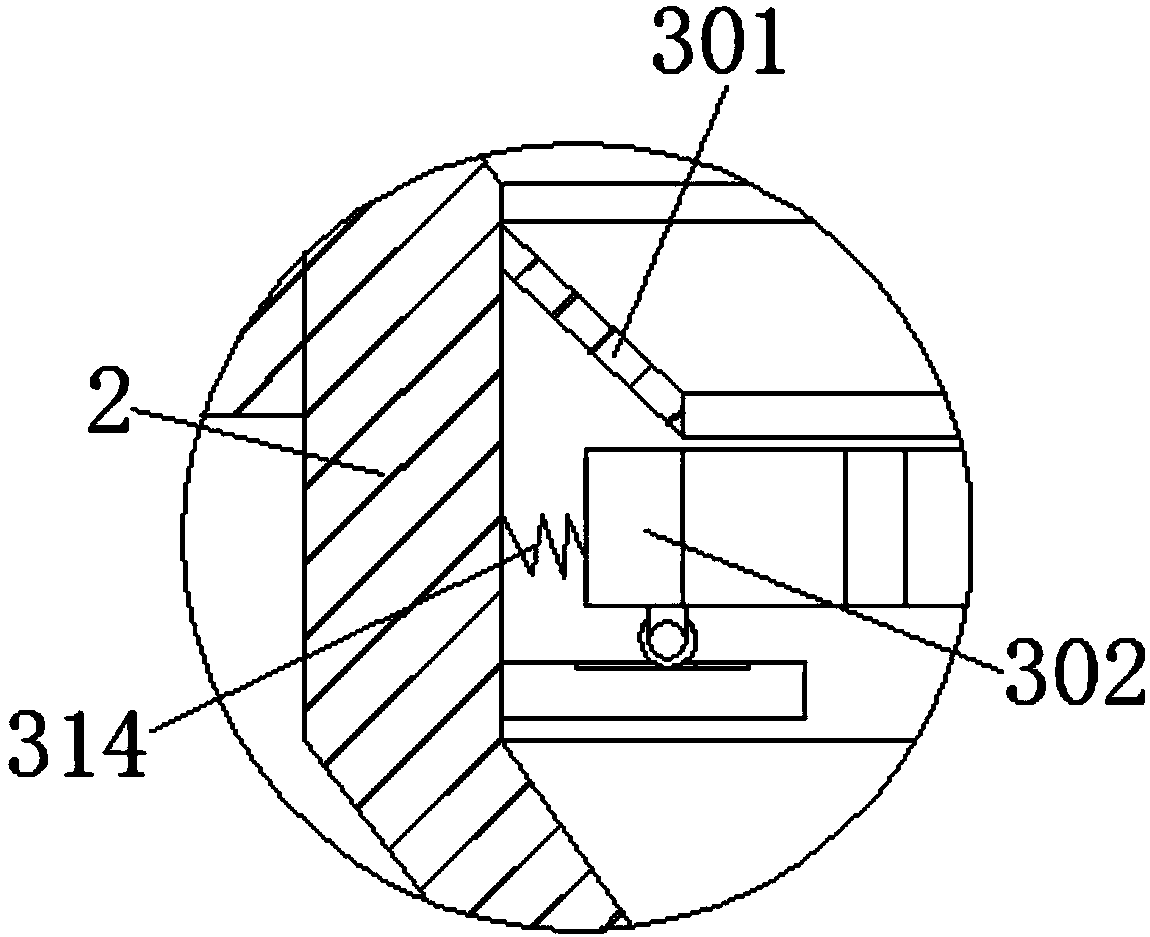

[0034] Embodiments of the present invention provide a peeling device for peeling fried peanuts based on bionic rubbing, such as Figure 1-6 As shown, it includes a casing 1, the top of the casing 1 is connected with a feed hopper 2, the inside of the feed hopper 2 is provided with a stable feeding device 3, and the inside of the casing 1 is connected to a peeling device on the feed hopper 2 4. The rotation of the motor 501 can simultaneously drive the stable conveying device 3 and the peeling device 4 to operate at the same time. The stable conveying device 3 and the peeling device 4 share the same power source, which can save their manufacturing costs and reduce the waste of resources. The peeling device 4 is connected with a transmission device 5, and the inside of the casing 1 is fixedly connected with the discharge funnel 6 below the transmission de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com