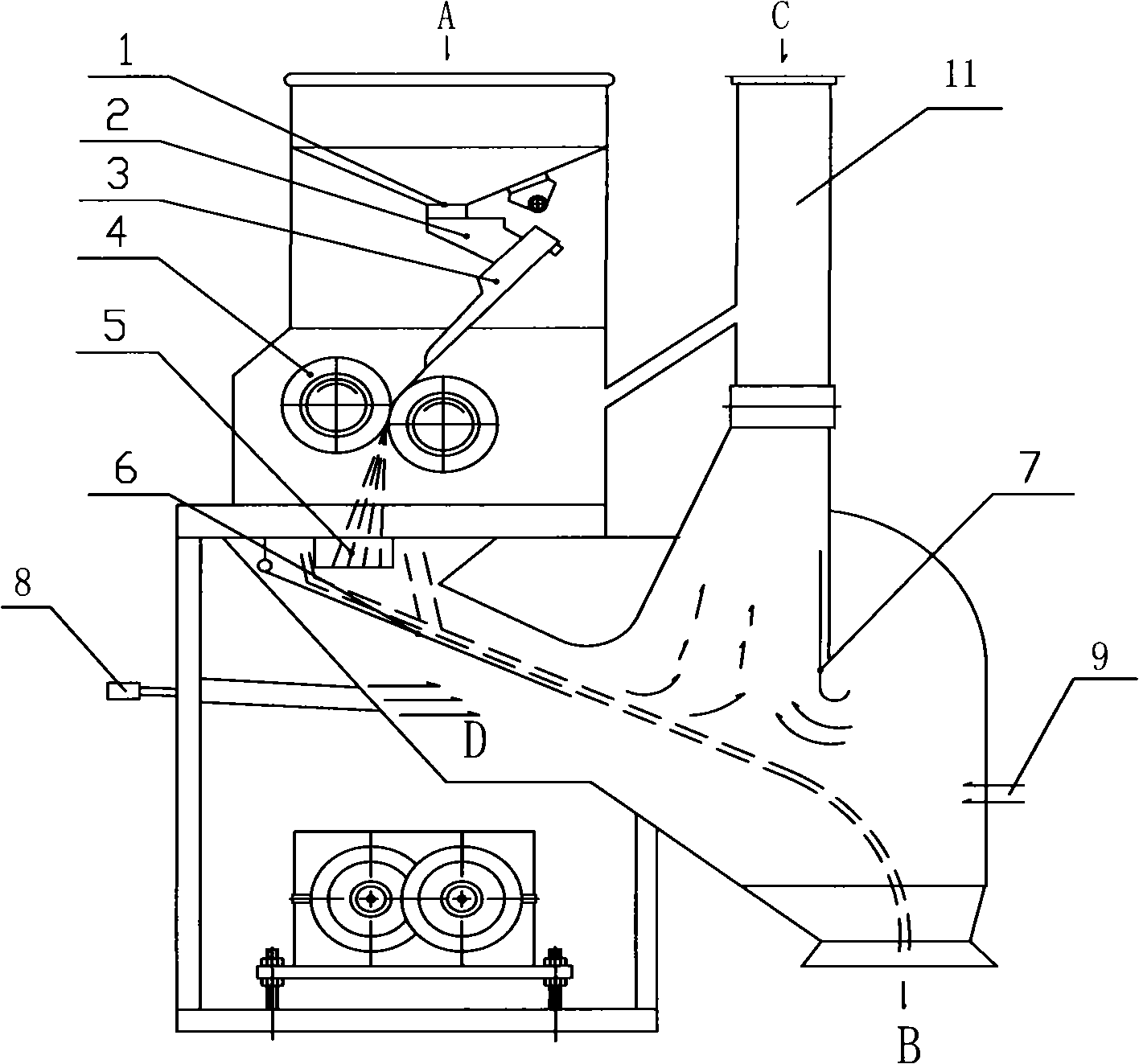

Oat barking equipment and barking method

An equipment and oat technology, applied in grain processing, application, grain pod removal, etc., can solve the problems of nutrient loss, damage integrity, etc., and achieve the effects of high nutritional value, short production time, and simple combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

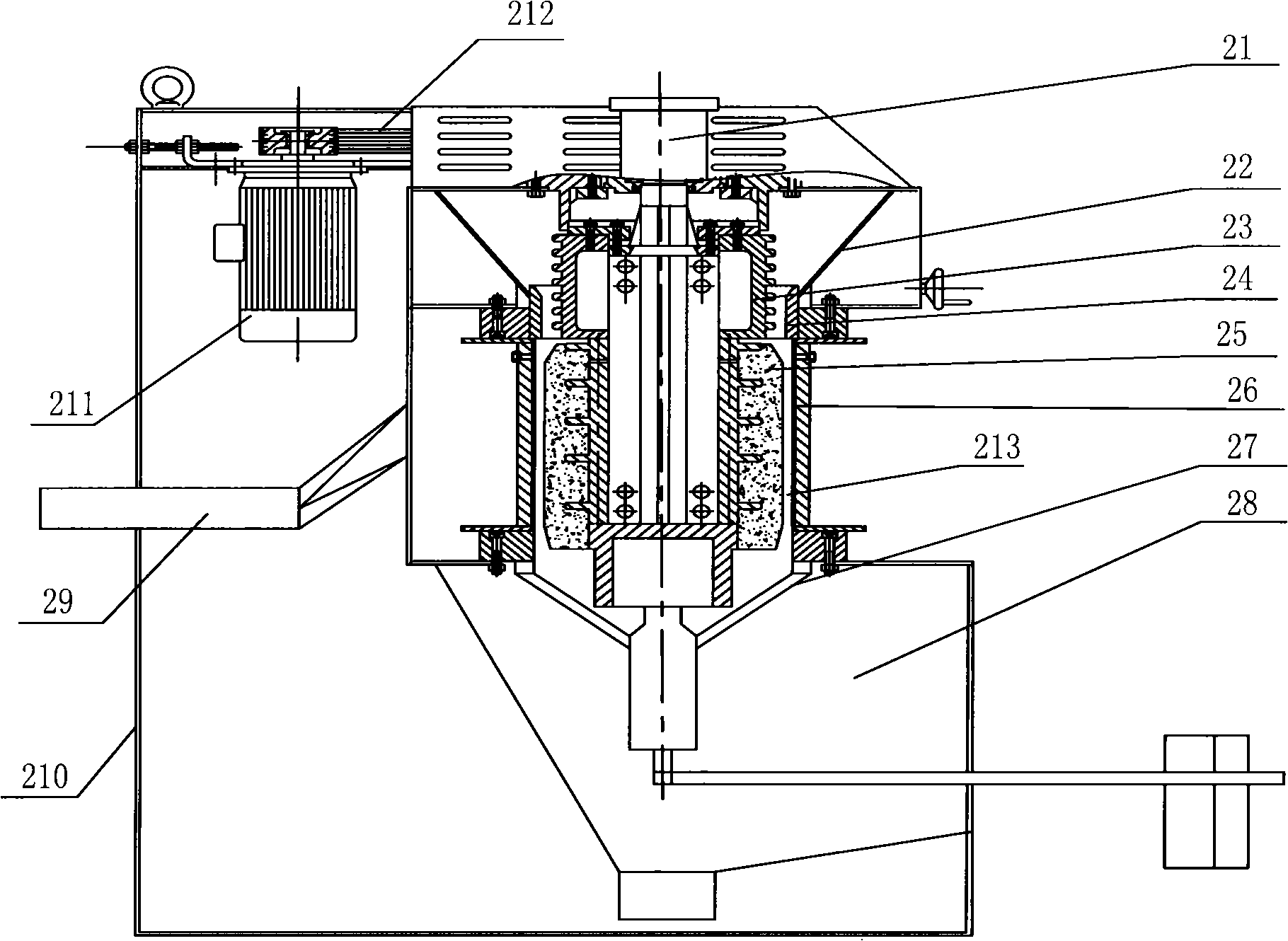

[0035] Such as figure 2 As shown, the present embodiment provides an oat peeling equipment for peeling oats, and the equipment includes: a frame 210, a feeding assembly, a propeller, an emery roller assembly 25 and a power unit 211;

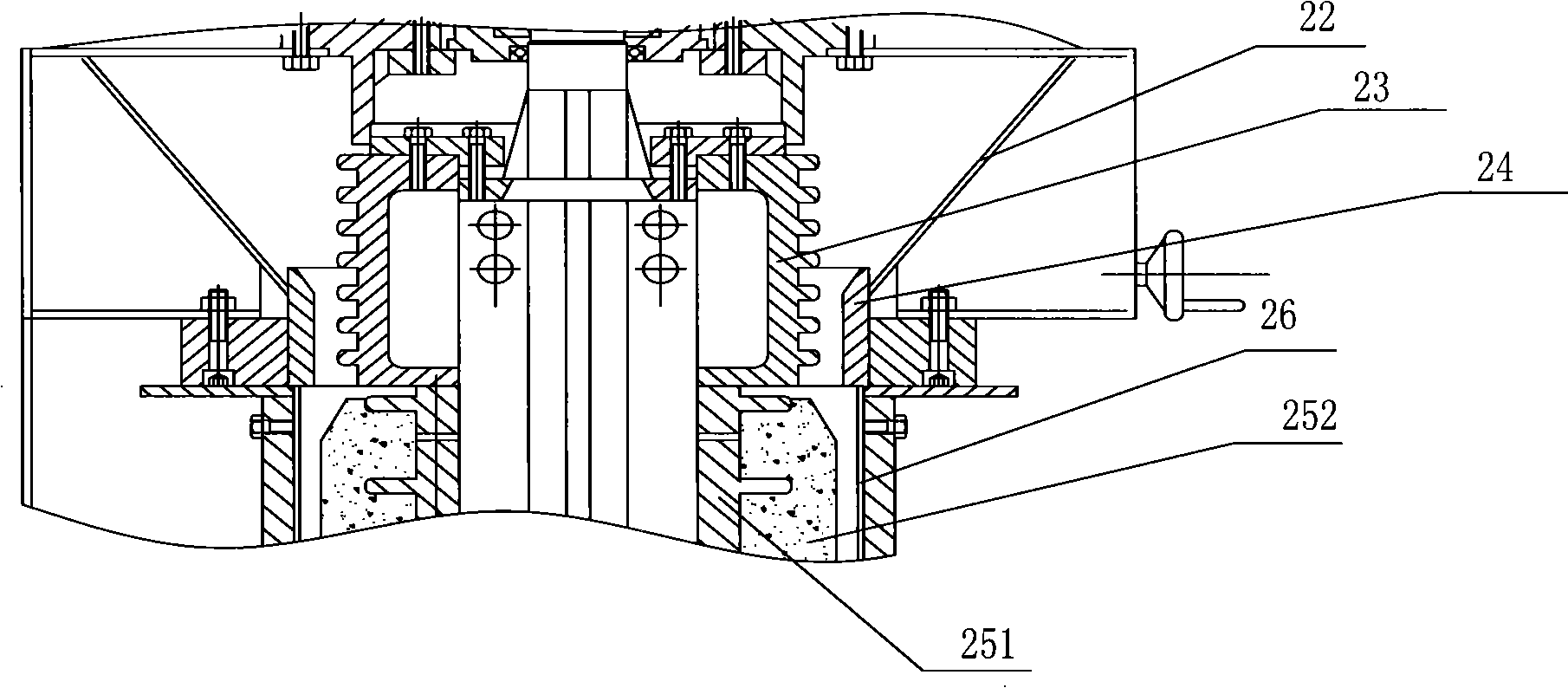

[0036] The frame 210 is used to set each part; the feed assembly provided on the frame 210 is composed of a feed cylinder 21 and a cone bucket 22, the feed cylinder 21 is arranged on the cone bucket 22, and the feed cylinder 21 outlet and the cone bucket 22 enter Corresponding to the feed port, the lower end of the cone bucket 22 is provided with a discharge port as the discharge port of the feed assembly; a propeller is arranged in the feed assembly, and the propeller is arranged in the cone bucket 22 of the feed assembly, and the lower end of the propeller passes through the cone bucket 22 The discharge port at the lower end, the propeller body corresponds to the discharge port at the lower end of the cone bucket 22, and a feed bushing 24 can ...

Embodiment 2

[0044] This embodiment provides a method for peeling oats, mainly using the peeling equipment mentioned in the first embodiment above to perform peeling treatment on oats, specifically as Figure 4 As shown, it includes: putting the oat material to be peeled into the feeding assembly of the peeling equipment, and the propeller in the feeding assembly is driven by the power device to transport the oat material to the peeling chamber between the sand board and the sand roller assembly In the peeling room, the oat material moves downward in a spiral motion driven by the sand roller assembly. During the spiral movement, the oat material passes through the action of the sand roller assembly and the sand plate, and the oat skin is peeled off in the peeling room. After peeling The oat grains are discharged from the discharge port of the peeling chamber, and the peeled oat skin enters the discharge hopper through the discharge port of the peeling chamber, and is discharged by the air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com