Manufacturing method for rigid substrate and flexible display device and rigid substrate

A technology of rigid substrate and fabrication method, applied in semiconductor/solid-state device manufacturing, electric solid-state device, semiconductor device, etc., can solve the problems of long etching time, poor selectivity, etching residue, etc., to shorten the etching time, The effect of improving the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The structure and principle of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

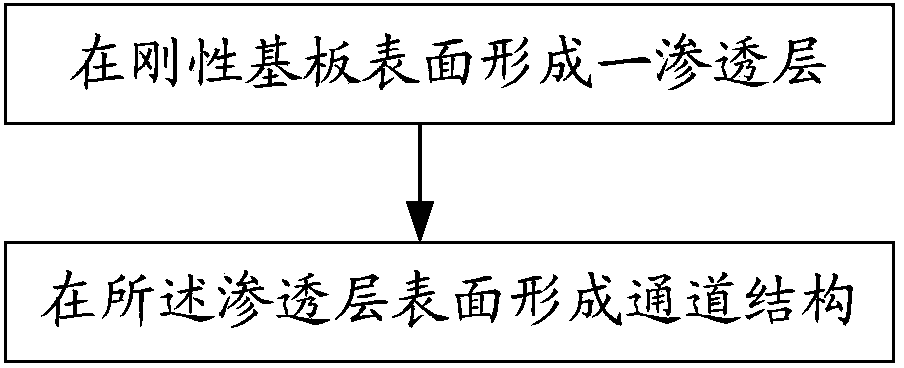

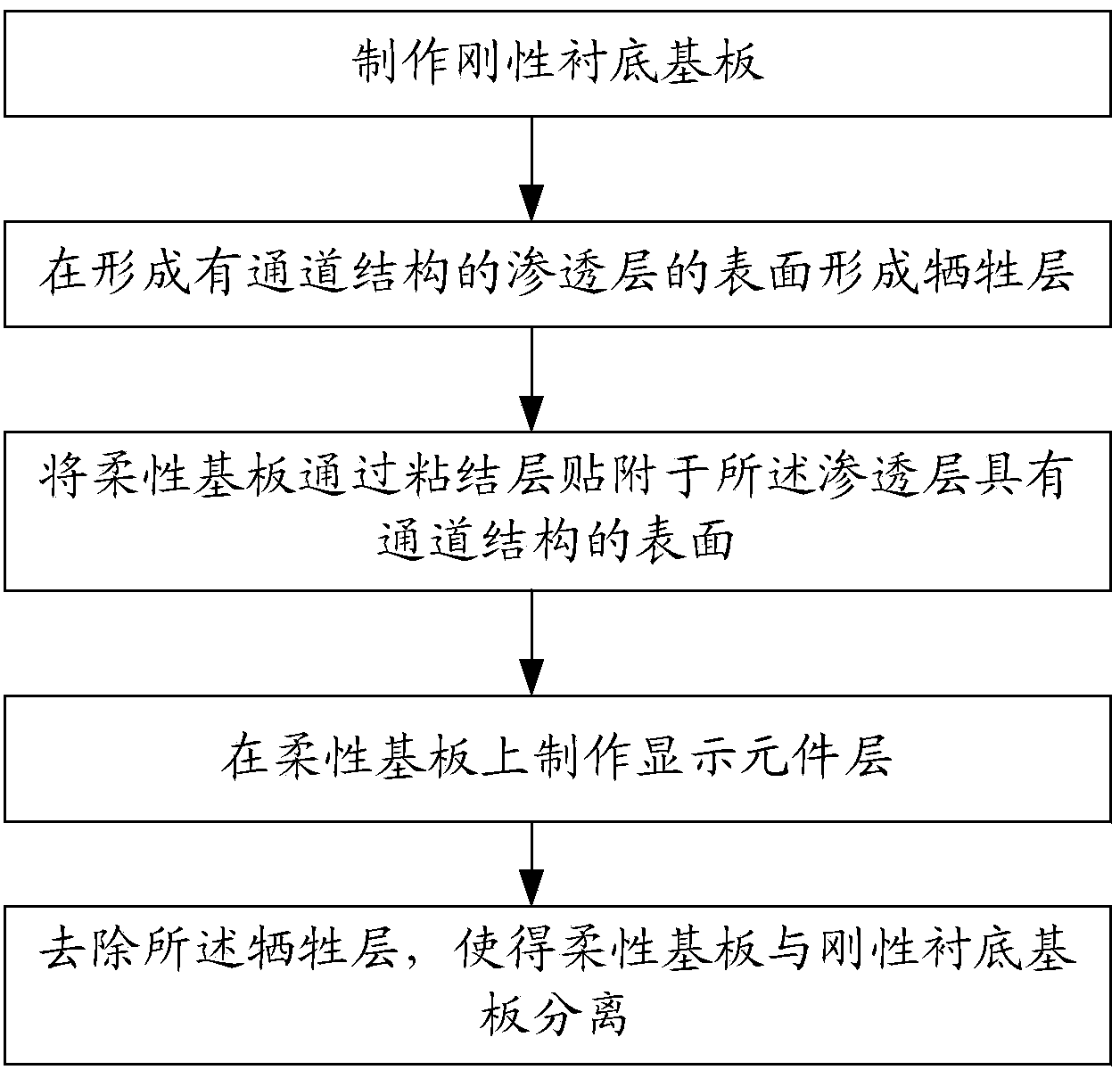

[0044] Such as figure 1 As shown, a method for manufacturing a rigid base substrate is used for the manufacture of a flexible display device, comprising the following steps:

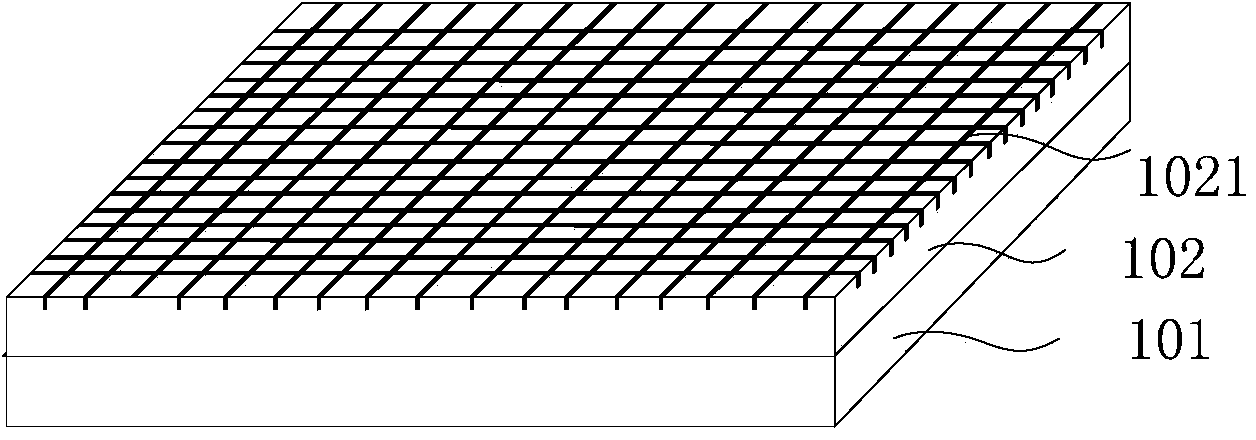

[0045] forming a permeable layer on the surface of the rigid substrate;

[0046] A channel structure is formed on the surface of the permeable layer.

[0047] The setting of the permeable layer with a channel structure allows the liquid for removing the sacrificial layer to quickly enter the interior of the permeable layer, contact the sacrificial layer to remove the sacrificial layer, increase the contact area between the sacrificial layer and the liquid used to remove the sacrificial layer, and shorten the sacrificial layer. The et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com