Packaging material and molded case

A packaging material, heat-resistant resin technology, used in transportation and packaging, battery box/sleeve materials, electronic equipment, etc., can solve problems such as insufficient adhesion, damage to uniform coloring, etc., to achieve excellent formability, good smoothness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

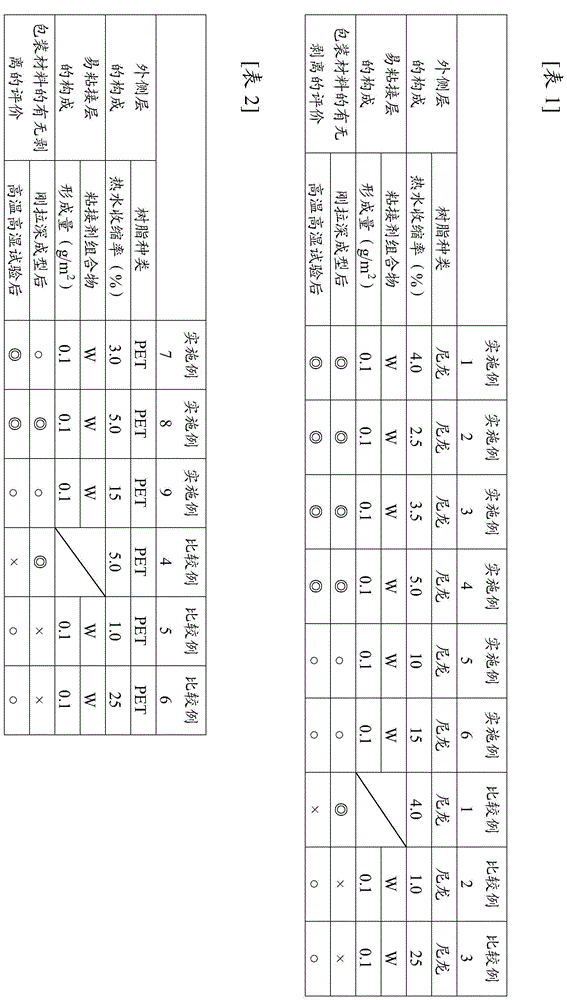

Embodiment 1

[0124] 50 parts by mass of carbon black with an average particle diameter of 0.8 μm, 5 parts by mass of ethylenediamine, and 45 parts by mass of polyester-based polyol (number average molecular weight: 2500) were blended to obtain a main ingredient. An ink composition was obtained by blending 3 parts by mass of toluene diisocyanate (TDI) as a curing agent with respect to 100 parts by mass of the above-mentioned main agent, and further blending 50 parts by mass of toluene.

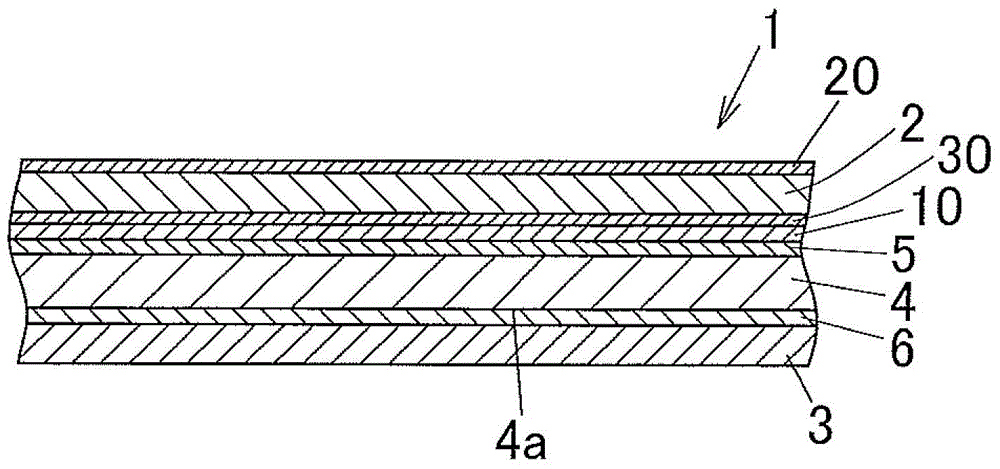

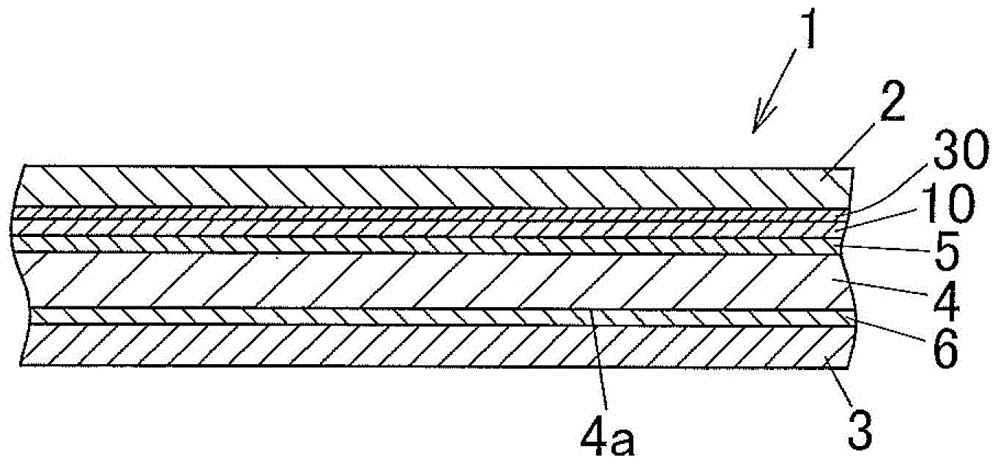

[0125] The above-mentioned adhesive composition W was coated by a gravure roll coating method on a biaxially stretched nylon (6 nylon) film (resistant to Thermal resin stretch film layer, MD / TD=0.95) 2 side, after drying, place it in 40°C environment for 1 day, so as to carry out curing reaction, and form an easy-bonding layer 30, and its formation amount is 0.1g / m 2 .

[0126] Next, the above-mentioned ink composition was printed (coated) on the surface of the easily-adhesive layer 30 of the above-mention...

Embodiment 2

[0131] A biaxially stretched 6 nylon film (MD / TD=0.9) with a thickness of 15 μm and a shrinkage rate of 2.5% in hot water obtained by stretching by a simultaneous biaxial stretching method was used instead of a film with a thickness of 15 μm and a shrinkage rate of 4.0% in hot water. Biaxially stretched 6 nylon film (MD / TD = 0.95), except that, in the same manner as in Example 1, to obtain figure 1 Packing material 1 shown.

Embodiment 3

[0133] A biaxially stretched 6-nylon film (MD / TD=1.0) with a thickness of 15 μm and a hot water shrinkage rate of 3.5% obtained by stretching by a simultaneous biaxial stretching method was used instead of a film with a thickness of 15 μm and a hot water shrinkage rate of 4.0%. Biaxially stretched 6 nylon film (MD / TD = 0.95), except that, in the same manner as in Example 1, to obtain figure 1 Packing material 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com