Fully-automatic packaging machine for heat shrinkable film

A heat shrinkable film and packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as unsatisfactory work performance, troublesome operation, complex structure, etc., reduce product lanes, facilitate operation and maintenance, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

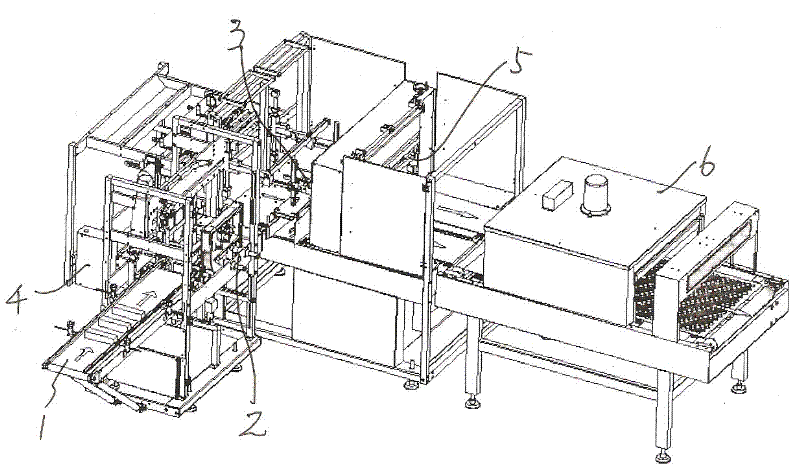

[0029] A fully automatic heat shrinkable film packaging machine, comprising a feeding conveyor belt 1, a stacking and scraping mechanism 2 is arranged above the feeding conveyor belt, a wrapping conveying mechanism 3 is arranged after the stacking and scraping mechanism, and a delivery mechanism is arranged behind the wrapping conveying mechanism. A film mechanism 4, a film covering mechanism 5 is arranged behind the film feeding mechanism, and an oven 6 is arranged behind the film covering mechanism.

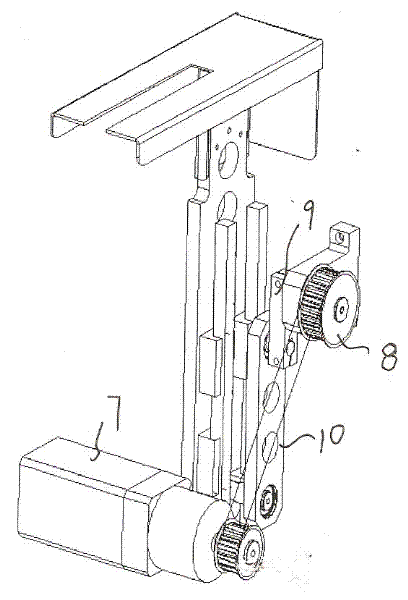

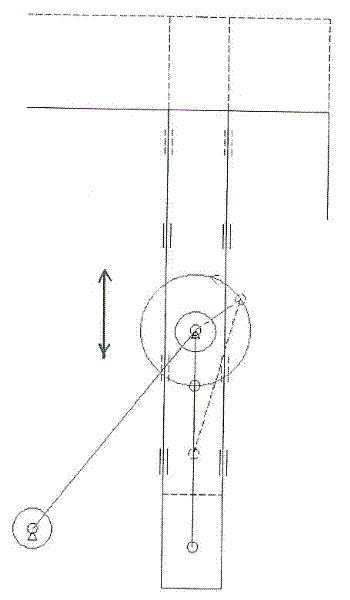

[0030] The stacking and scraping mechanism includes a stacking device for stacking the items sent by the conveyor belt and a scraping device for pushing the stacked items to the wrapping conveying mechanism; the principle of the stacking mechanism: the servo motor 7 is decelerated by a reducer Then drive the synchronous belt pulley 8, and then drive the connecting rod 10 to move through the connecting rod 9, so that the stacking plate is image 3 The movement trajectory shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com