RWD automobile gearbox transmission error detection test bench and comprehensive testing method

A technology of automobile gearbox and transmission error, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of low measurement and control accuracy, large energy consumption, etc., and achieve the effect of improving versatility, reducing investment and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

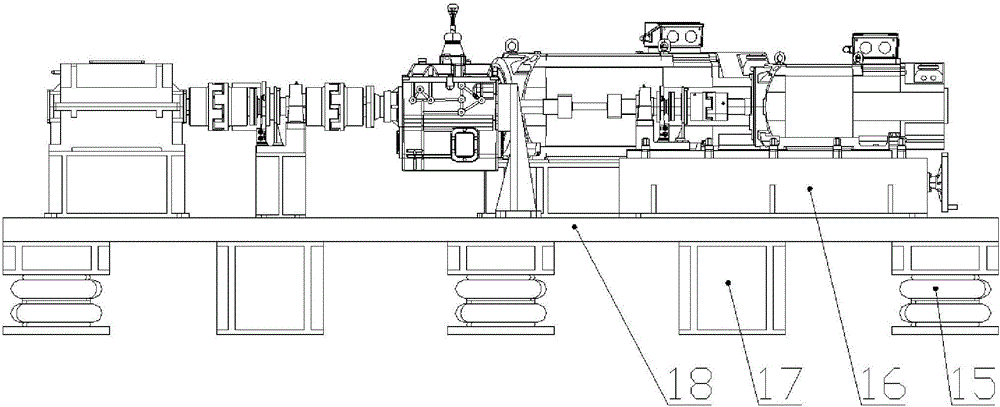

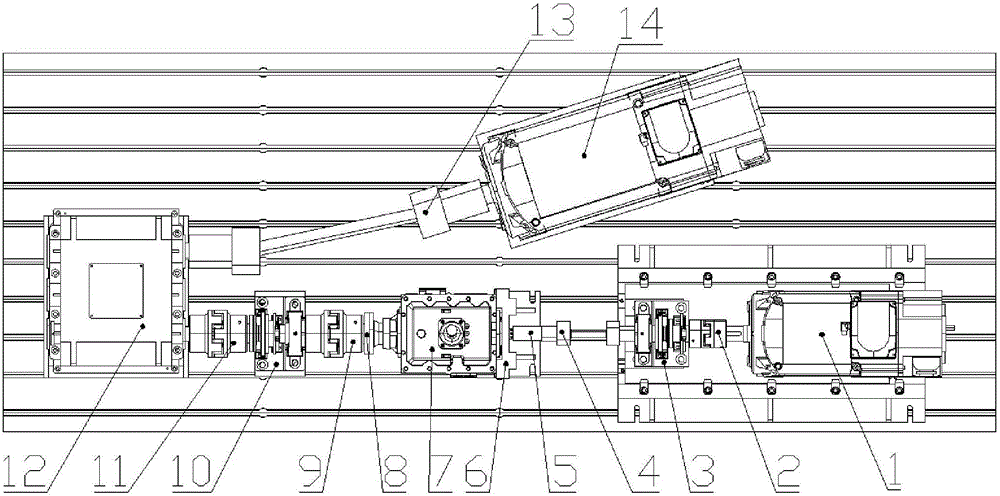

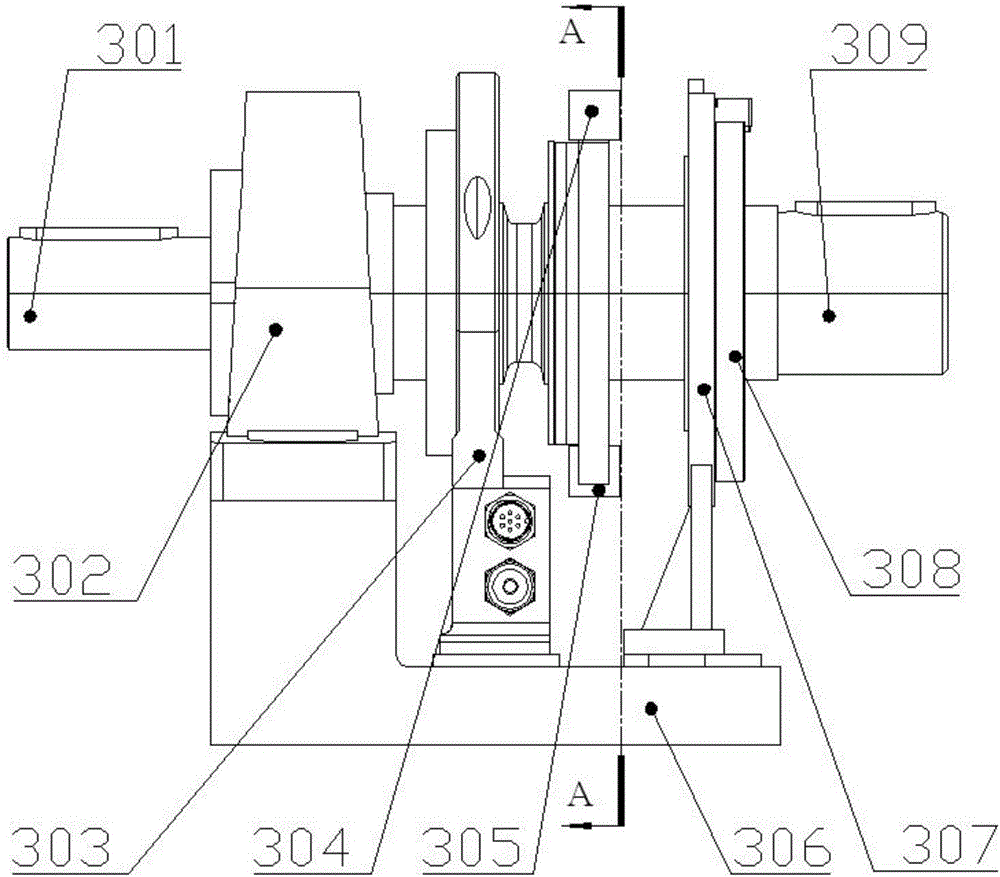

[0056] The bottom of the T-slot installation platform 18 is respectively connected with the T-slot installation platform rigid support seat 17 and the air spring support device 15, and the AC drive motor sliding table base 16 and the special clamp 6 for the gearbox are respectively installed above the T-slot installation platform 18. The AC drive motor 1 and the input end transmission error comprehensive detection device 3 are installed on the AC drive motor slide base 16, the output end of the AC drive motor 1 is connected to the input end transmission error comprehensive detection device 3 through the input end elastic coupling 2 , the transmission error comprehensive detection device 3 at the input end is connected with the input spline shaft 5 of the gearbox through the spherical cage synchronous universal coupling 4 at the input end; The output shaft of the gearbox is connected to the output flange shaft 8 of the gearbox, and the output end transmission error comprehensive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com