Hub assembly of disc type variable-speed motor of electric vehicle

A technology for electric vehicles and variable speed motors, applied to electric vehicles, motors, electric components, etc., can solve problems such as insufficient starting torque, unreasonable installation, complex structure, etc., and achieve increased output power, improved output power, and simple structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

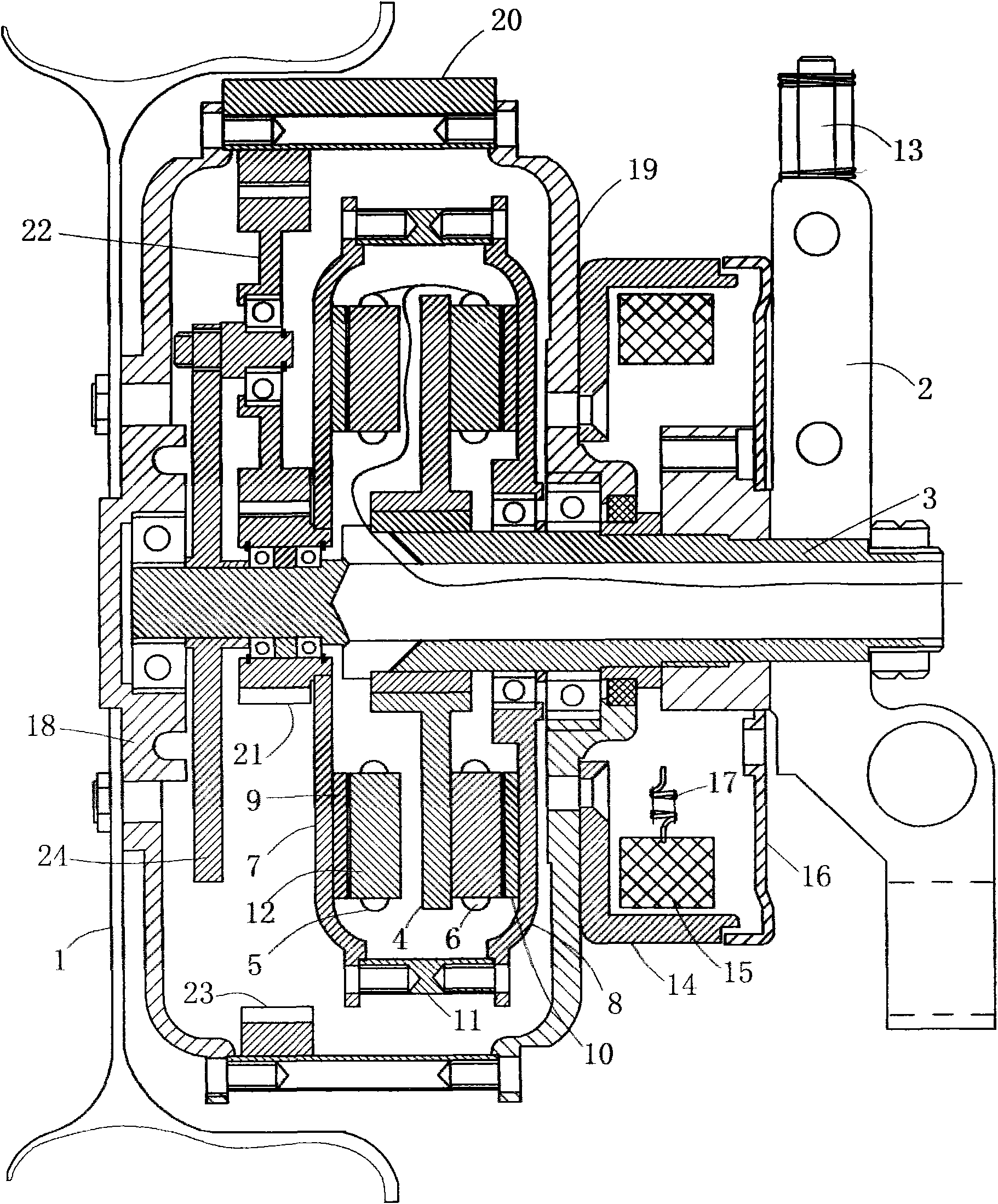

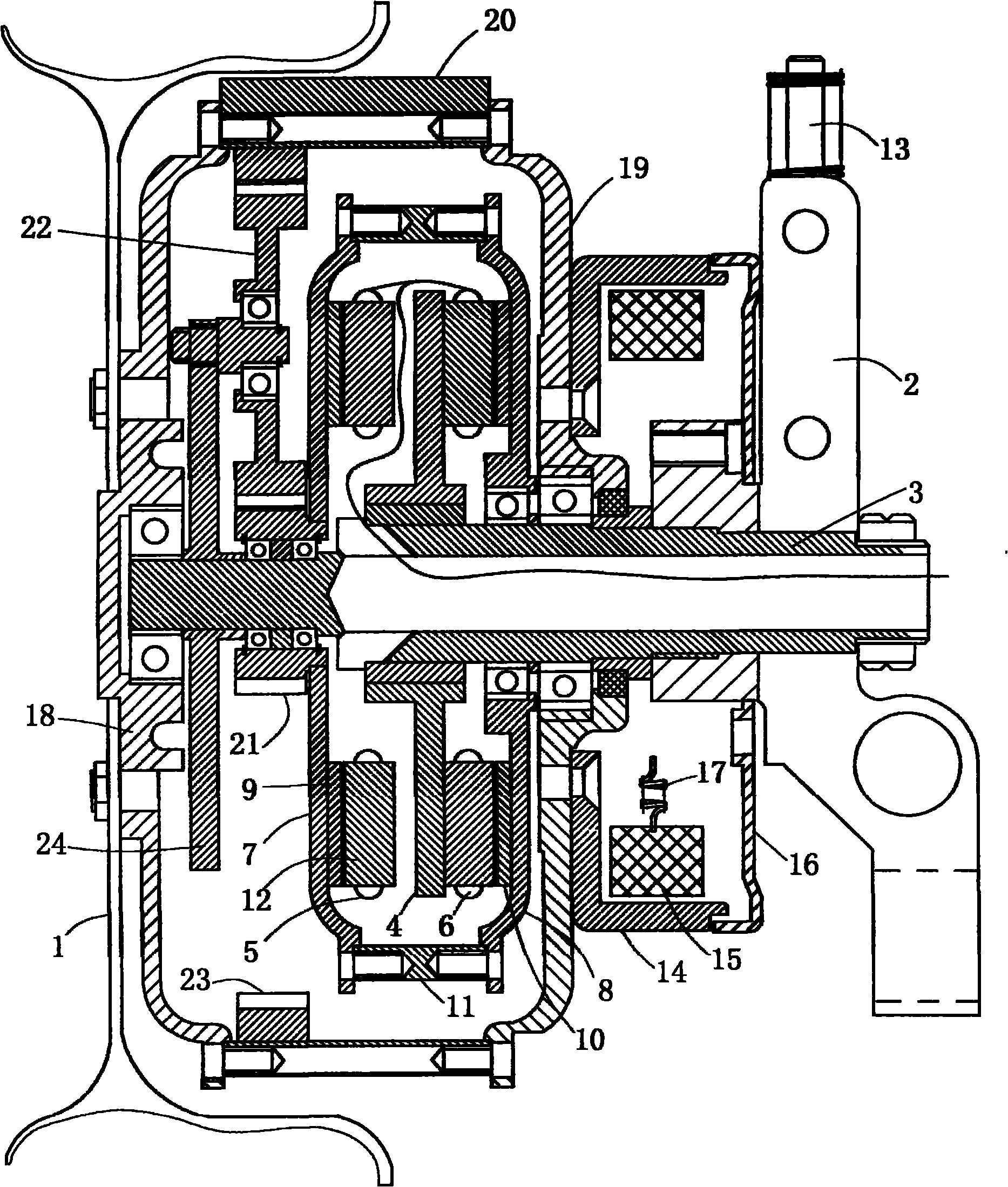

[0022] As shown in the drawings, a disc-type variable speed motor hub assembly for an electric vehicle is installed between the rim 1 and the suspension horn 2, and includes a stator shaft 3 for fixed installation on the suspension horn 2 of the electric vehicle. A stator assembly is fixed on the stator shaft 3, the outer periphery of the stator assembly is surrounded by an inner rotor assembly, the outer periphery of the inner rotor assembly is provided with an outer rotor assembly, and the outer rotor assembly is fixedly installed on the On the rim 1, a transmission device is provided between the inner rotor assembly and the outer rotor assembly, and the transmission device mainly includes an inner ring gear 23, a sun gear 21 and a planetary gear 22, wherein the inner ring gear 23 is fixed Installed on the outer rotor assembly; the sun gear 21 is rotatably installed on the stator shaft 3; the planetary gear 22 is meshed and arranged between the inner ring gear 23 and the sun ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com