Ultrahigh-precision numerically-controlled non-circular curved surface composite grinder

A compound grinding and precision technology, applied in the direction of grinding machine, grinding bed, grinding machine parts, etc., can solve the problems that the grinding machine cannot grind the plane, cannot be realized, and has a single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

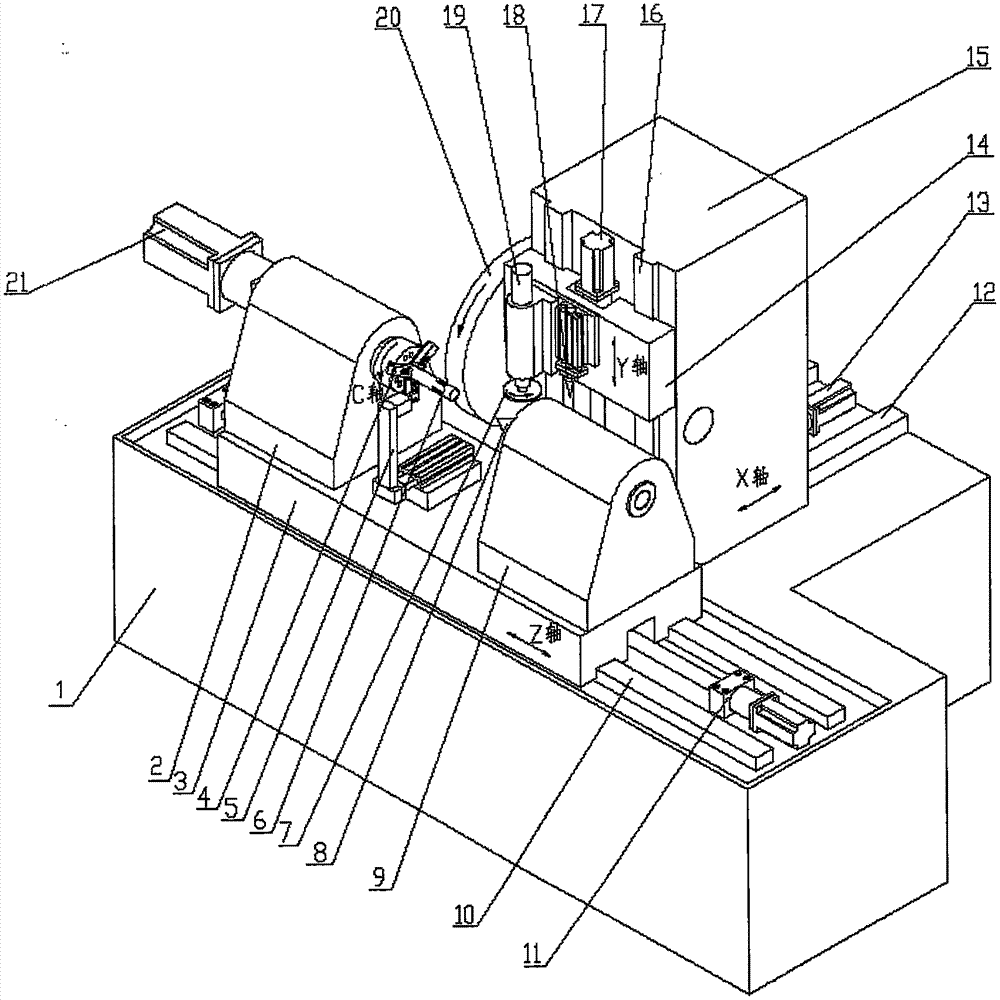

[0023] refer to figure 1 As shown, the workbench 3 is equipped with a headstock 2, a tailstock 9 and a measuring device A5. After the workpiece chuck 4 clamps the workpiece, the tailstock tip 8 tightens the workpiece, and the Z-axis moving drive system 11 drives the workbench 3 to The workpiece is moved to a suitable position along the Z-axis direction, and the measuring device B is moved down by the cylinder or oil cylinder, and the workpiece is initially measured and positioned, and then moved left and right to select the horizontal axis grinding wheel disc 20 or the vertical axis grinding wheel disc 7 For processing, the measuring device A5 on the workbench is driven close to the workpiece by the cylinder or oil cylinder, and the grinding control is carried out through the appropriate drive and linkage of the X-axis, Y-axis, Z-axis and C-axis. Among them, the Y axis is responsible for whether the vertical axis grinding wheel 7 is put into use and the vertical movement and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com