Sliding plate conveying system with accompanied lifting function

A conveying system and sliding plate technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as unfavorable upgrade and reconstruction, difficult to achieve online adjustment of workpiece height, difficult to repair and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

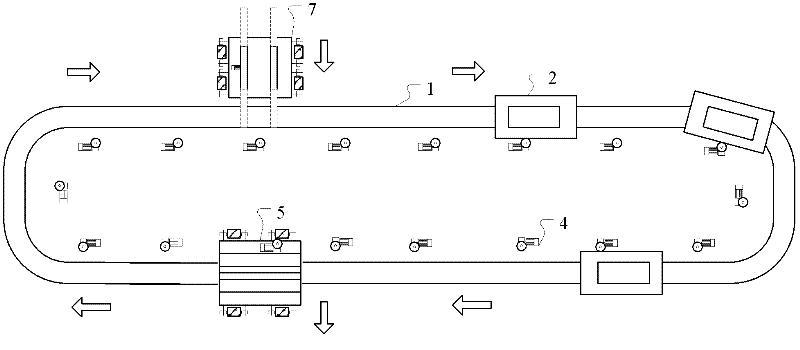

[0061] like figure 1 As shown, the skateboard conveying system with accompanying lifting function in Embodiment 1 is mainly composed of a track 1, a skateboard device 2, a friction wheel drive device 4, a lower lifting platform device 5 and an upper lifting platform device 7.

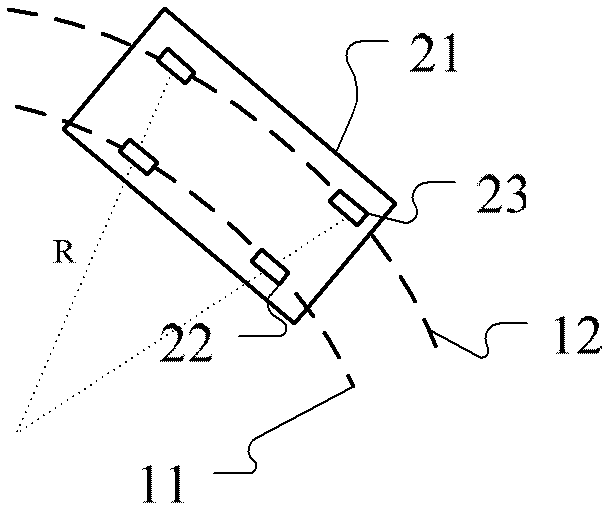

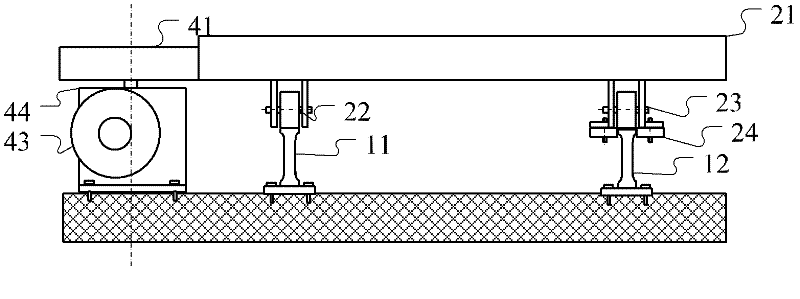

[0062] like Figure 1~Figure 3 As shown, the track 1 is a closed ring, the track 1 is in the same plane, and the turning point of the track 1 is provided with a circular arc transition section for realizing the turning of the skateboard device 2 during driving; several skateboard devices 2 are arranged on the track 1 And can travel along track 1, slide plate device 2 is used for loading workpiece; This track 1 comprises inner guide rail 11 and outer guide rail 12 that are arranged in parallel; The track wheels 23 are composed of two inner track wheels 22 installed on the inner side of the bottom of the slide plate 21 one after the other, and placed on the inner guide rail 11 of the track 1; two outer t...

Embodiment 2

[0078] The skateboard conveying system with accompanying lifting function in embodiment 2 is mainly composed of track 1, skateboard device 2, friction wheel drive device 4, rotary table device 3, lower piece lifting platform device 5, transfer lifting platform device 6 and upper piece lifting platform The device 7 is composed.

[0079] Such as Figure 9 As shown, the track 1 is composed of a lower track 13 and an upper track 14 at different heights, and a transfer lifting platform device 6 for transferring the slide plate device 2 is arranged at the junction of the lower track 13 and the upper track 14 . Preferably, the track 1 is a ring structure, which is mainly composed of a lower straight track 131, an upper straight track 141, a lower U-shaped curved track 132 and an upper U-shaped curved track 142, and the lower U-shaped curved track 132 and the upper U-shaped curved track The turning point of the track 142 adopts a circular arc transition section; the lower track 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com