Wire grinding mechanism

A grinding mechanism and wire rod technology, applied in grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problems of low grinding precision, large impact force of machine head rotation, and large working noise. Achieve the effect of convenient maintenance and debugging, high grinding precision and low working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

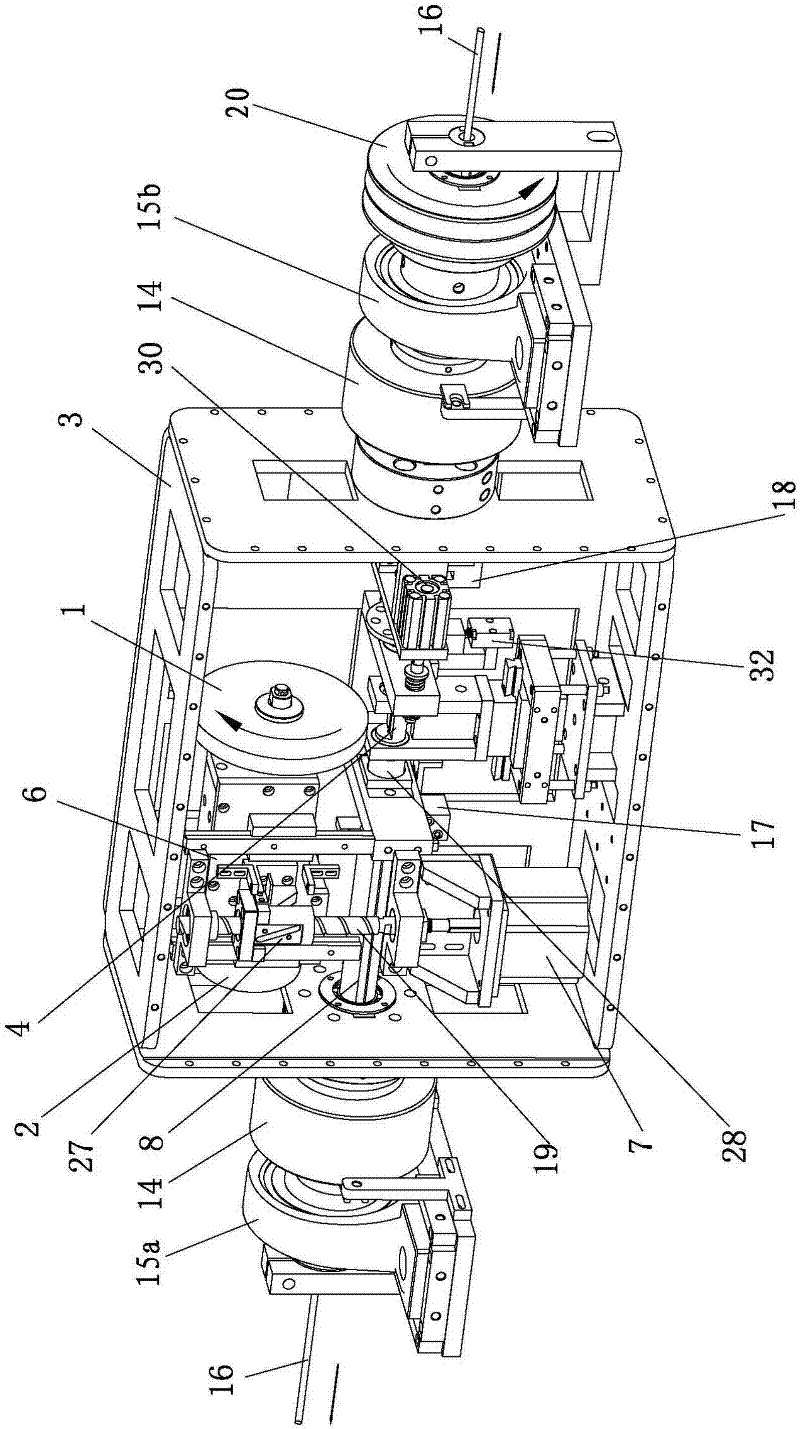

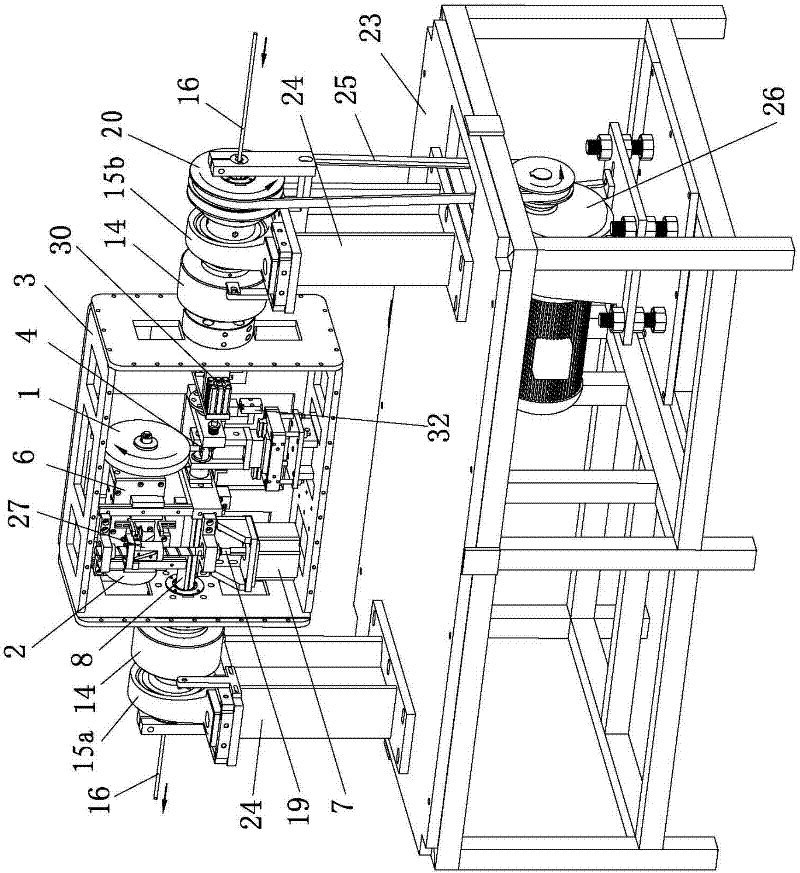

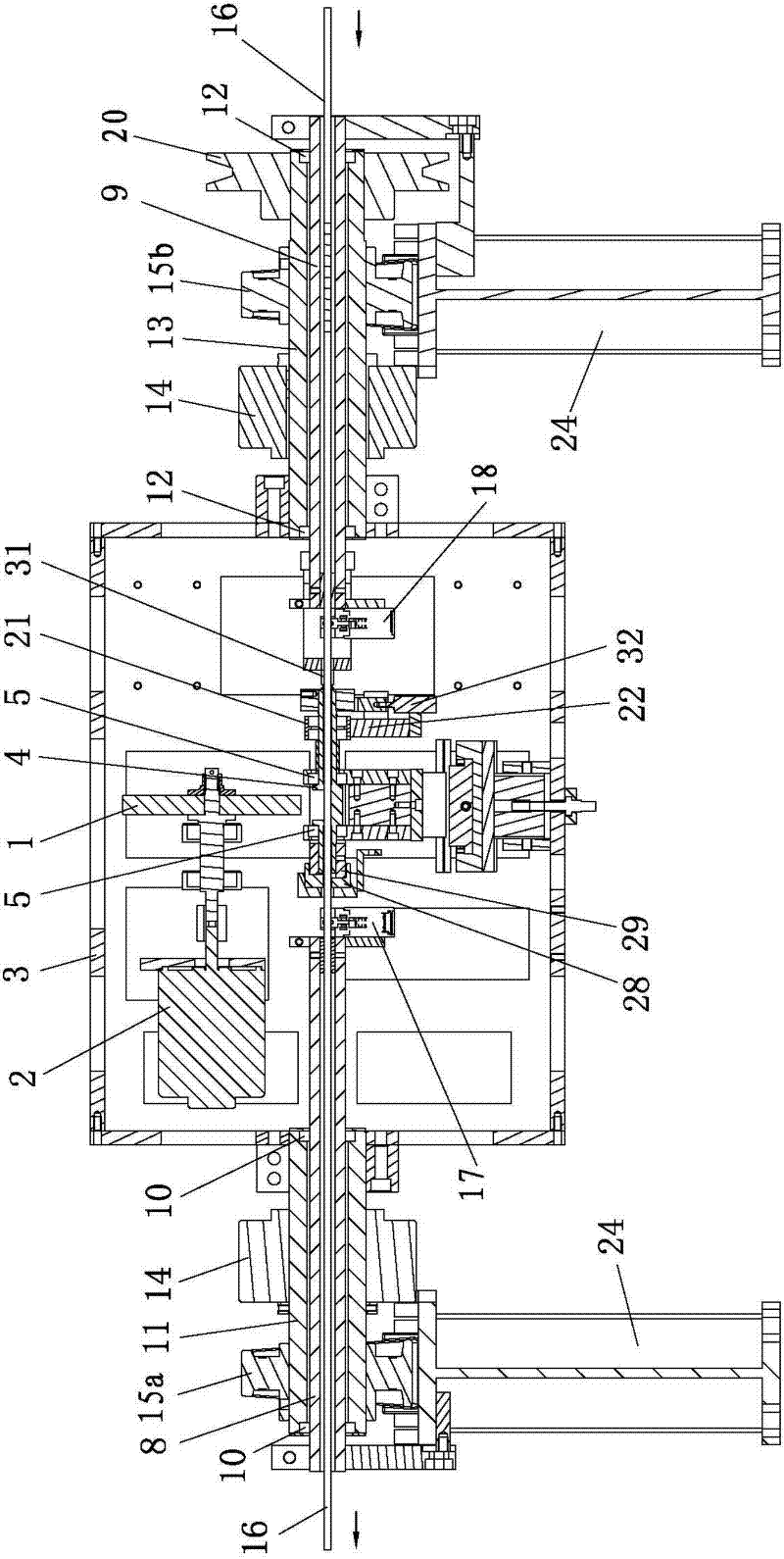

[0019] The invention discloses a wire rod grinding mechanism. The wire rod to be polished is fixed in the grinding mechanism, the grinding wheel rotation motor 2 drives the grinding wheel to rotate itself, and the revolution motor 26 drives the grinding wheel to revolve around the wire rod to grind the outer circular surface of the wire rod, and at the same time advance radially The motor 7 drives the emery wheel to move radially, so that a certain depth is ground on the wire rod. see figure 1 , the present invention at least includes a grinding wheel 1 and a grinding wheel rotation motor 2, a radial drive device for driving the grinding wheel and the grinding wheel rotation motor to move radially, a grinding shaft 4 that supports the wire 16 in the radial direction of the grinding wheel, and passes through the first bearing 5 The supporting device supporting the grinding shaft, the clutch device arranged between one end of the grinding shaft and the supporting device to facil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com