Automatic control device for uniform discharge of extruder

A technology of a homogenizing device and an extruder is applied in the field of devices that automatically control the uniform discharge of the extruder, which can solve the problems of difficult maintenance and debugging, uniformity of the length direction of the extruded product, uniformity of thickness and color uniformity. Good, complex structure and other problems, to achieve the effect of easy maintenance and debugging, easy operation, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

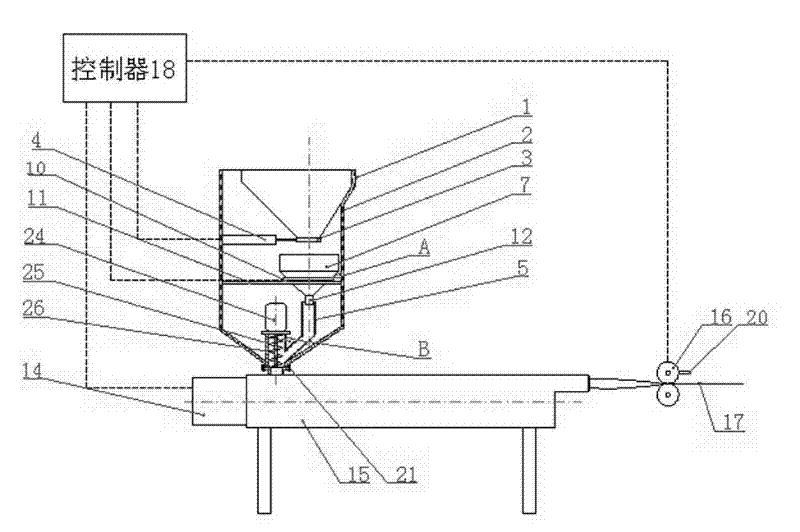

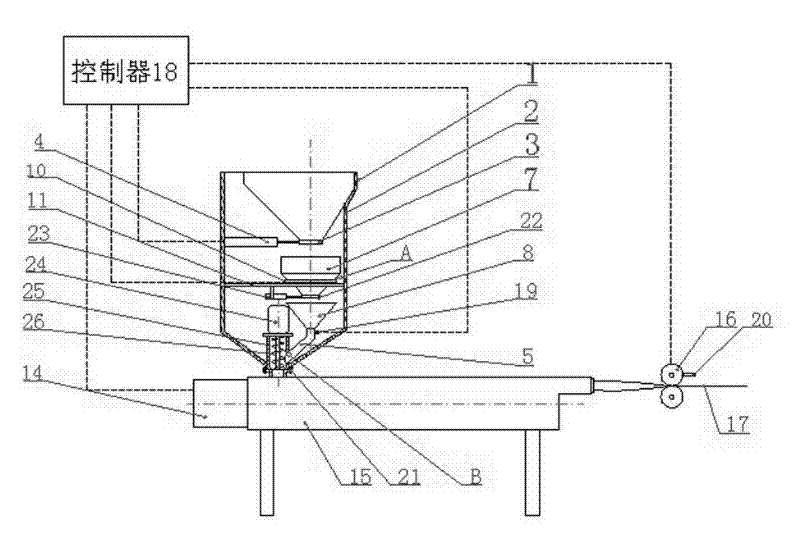

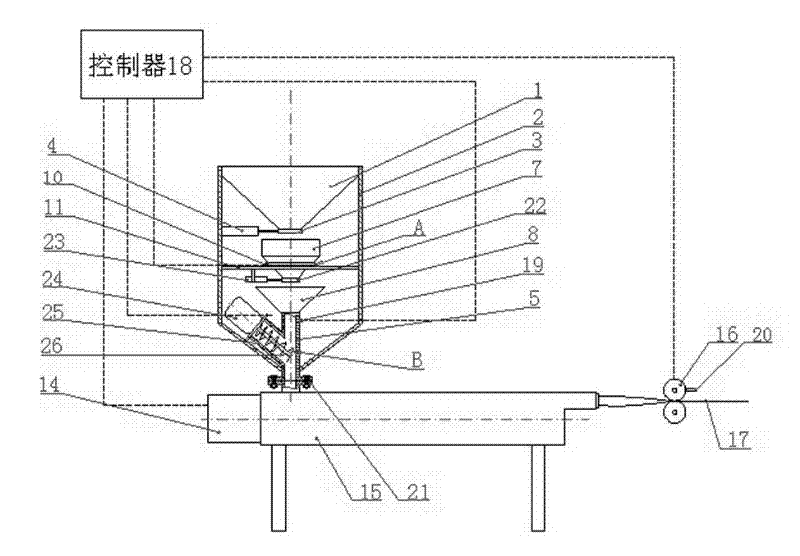

[0017] see Figure 1-Figure 3 , this embodiment of the present invention comprises controller 18, material hopper 1, frame 2, feed conduit 5 and weighing device A, and the input end of this controller 18 is connected with weighing device A, and the output end of this controller 18 It is connected with the motor 14 of the extruding screw of the extruder 15 or the driving motor of the traction roller 16 . The raw material hopper 1 and the feed conduit 5 are installed on the upper end and the lower end of the frame 2 respectively, and the lower end outlet of the feed conduit 5 is connected with the feed port of the extruder 15, and the raw material hopper 1 and the feed conduit A weighing device A is installed between 5. A raw material hopper gate 3 and a first driving device 4 connected thereto are installed at the outlet of the lower end of the raw material hopper 1 ; a leveling device B is installed at the lower part of the feed conduit 5 .

[0018] Weighing device A packs w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com