Large power ship shore electric power

A shore power supply and high-power technology, which is applied to the output power conversion device, the conversion of AC power input to AC power output, and the conversion of AC power input to DC power output, etc. The use of power supply derating, low input power factor, etc., to achieve the effect of good anti-electromagnetic interference ability, improve power factor, and reduce the harmonic components of input current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

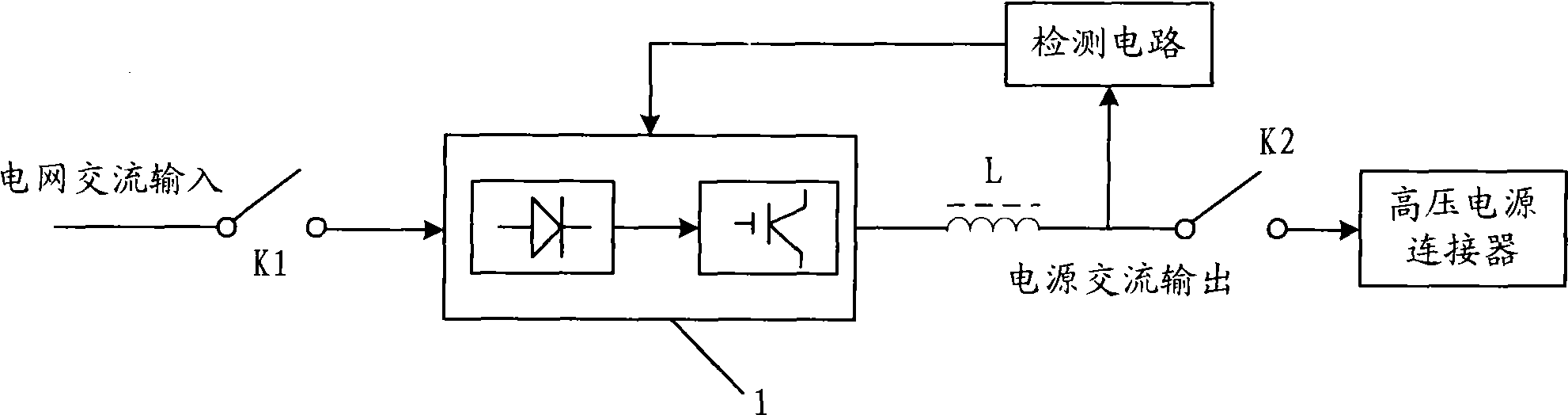

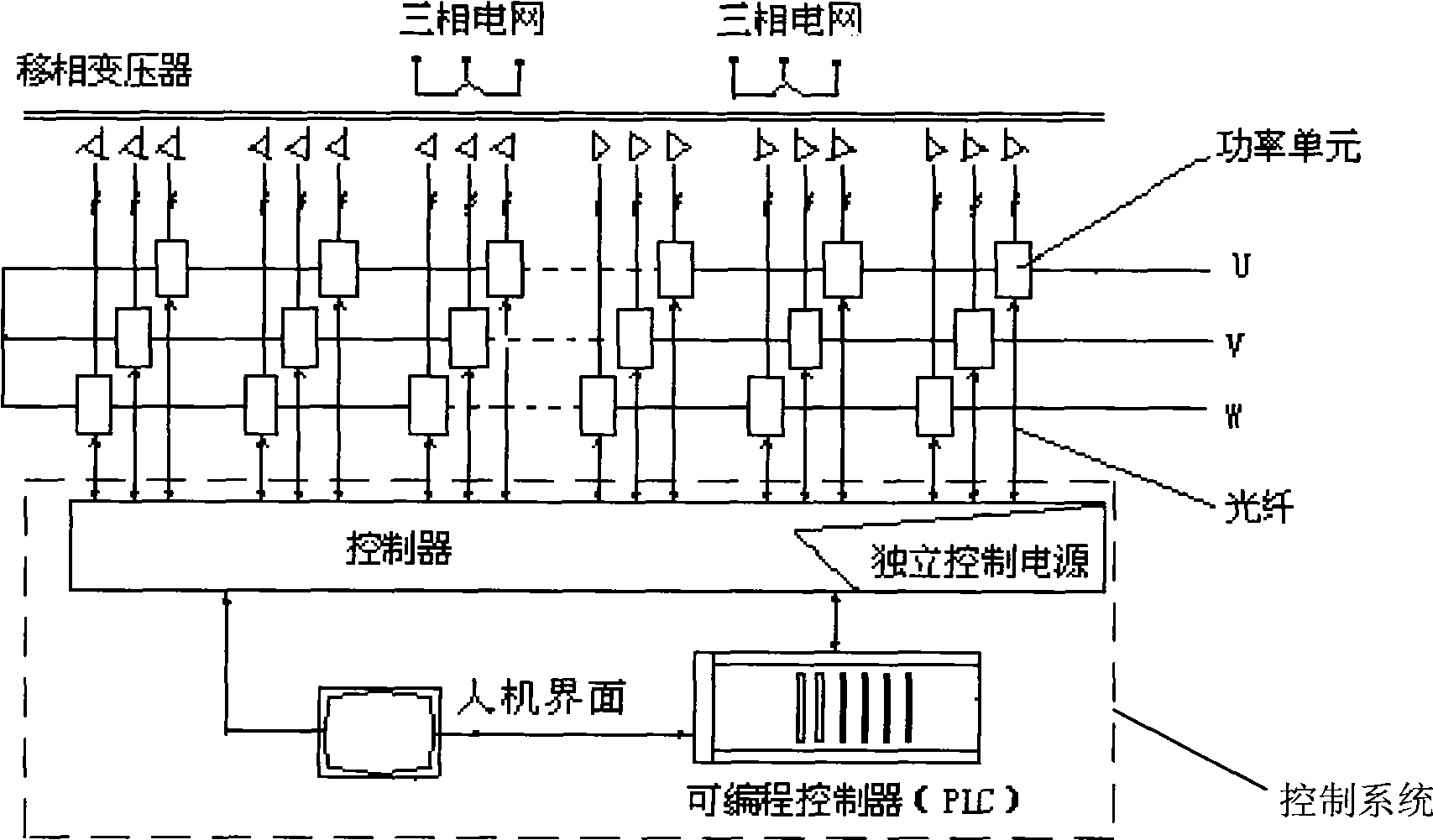

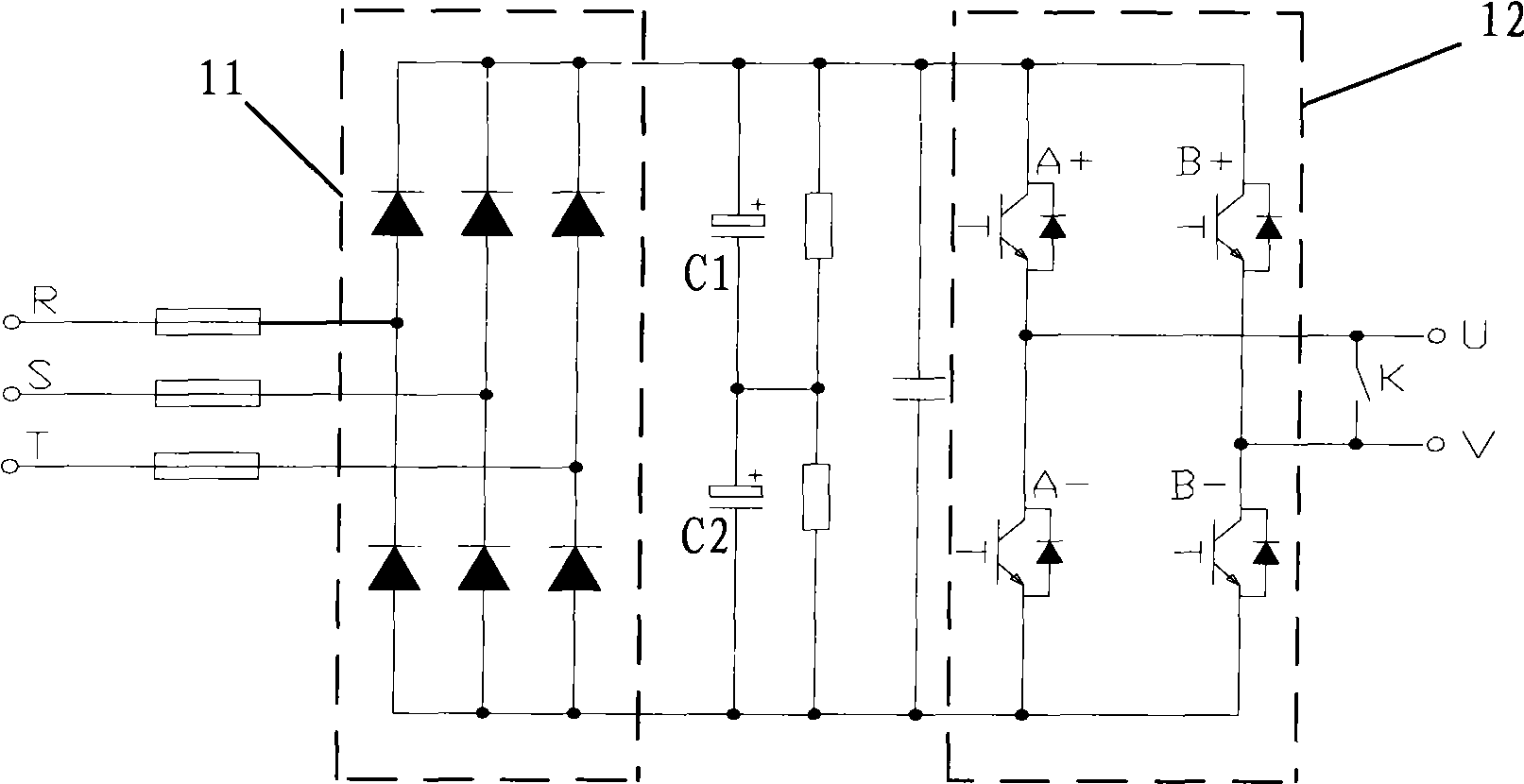

[0025] refer to figure 1 The principle block diagram of the shore power supply is shown. The shore power supply in the present invention is a power supply that uses land power grids to supply power to ships in port, especially ships in port with relatively large loads. The shore power supply includes an input switch K1 , a high-voltage inverter system 1 and an output switch K2 , and a high-voltage reactor L is connected in series at the output end of the high-voltage inverter system 1 . The substation in the port area redistributes the 50Hz power on land, and reduces the high-voltage 20-100KV voltage through a step-down transformer; then, the stepped-down 50Hz grid high-voltage AC input is transmitted to the input end of the shore power supply through cables. Close the switch K1 and the switch K2, the high-voltage AC input of the power grid is input into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com