Bourdon tube force feedback type 2D electrical-hydraulic pressure servo valve

A Bourdon tube force and feedback technology, applied to servo motor components, fluid pressure actuators, valve details, etc., can solve problems such as ineffective braking, poor control accuracy and response speed, and slow dynamic response. Reduce processing difficulty and cost, improve anti-pollution ability, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

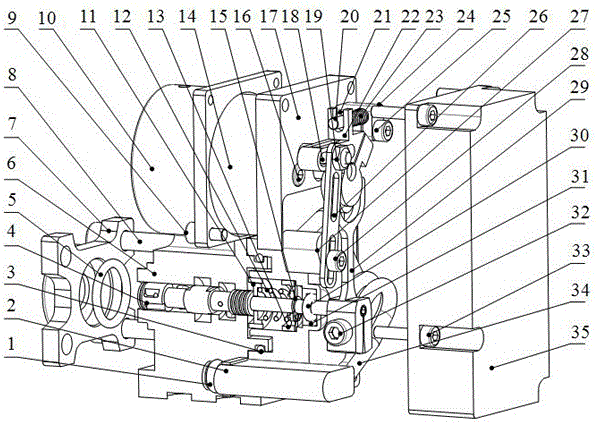

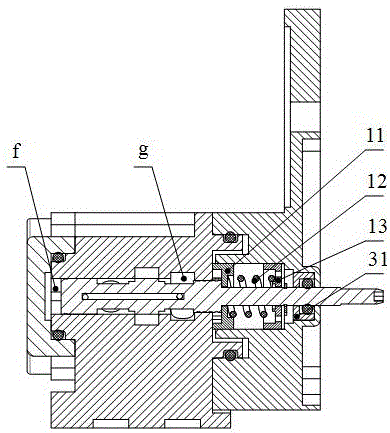

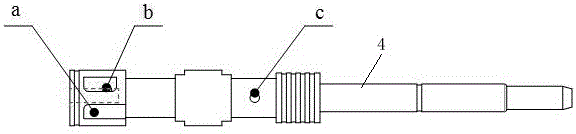

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] refer to Figure 1-Figure 7 , a Bourdon tube force feedback type 2D electro-hydraulic pressure servo valve includes a first screw 8, a second screw 9, a third screw 16, a fourth screw 25, a fifth screw 28, a sixth screw 32, and a seventh screw 33 And the eighth screw 36, the first O-ring 1, the second O-ring 3, the third O-ring 5, the fourth O-ring 30, the valve body 6, the valve core 4, the end cover 7, Connecting block 2, rotating electromagnet 14, electromagnet protective cover 10, return spring 12, left spring seat 11, right spring seat 13, retaining spring 15, connecting plate 17, pin 18, nut 19, spring holder 20, spring pad Sheet 21, upper lever 22, electromagnet zero position holding spring 23, spring holder support 24, connecting rod 26, threaded fixing rod 27, lower shift fork 29, shaft end sealing ring cover plate 31, Bourdon tube 34, Lid 35.

[0027] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com