Sucker rod rope suspension apparatus

A sucker rod and suspension rope technology, applied in drill pipe, production fluid, drilling equipment, etc., can solve problems such as single function, achieve the effect of advanced principle, novel structure and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

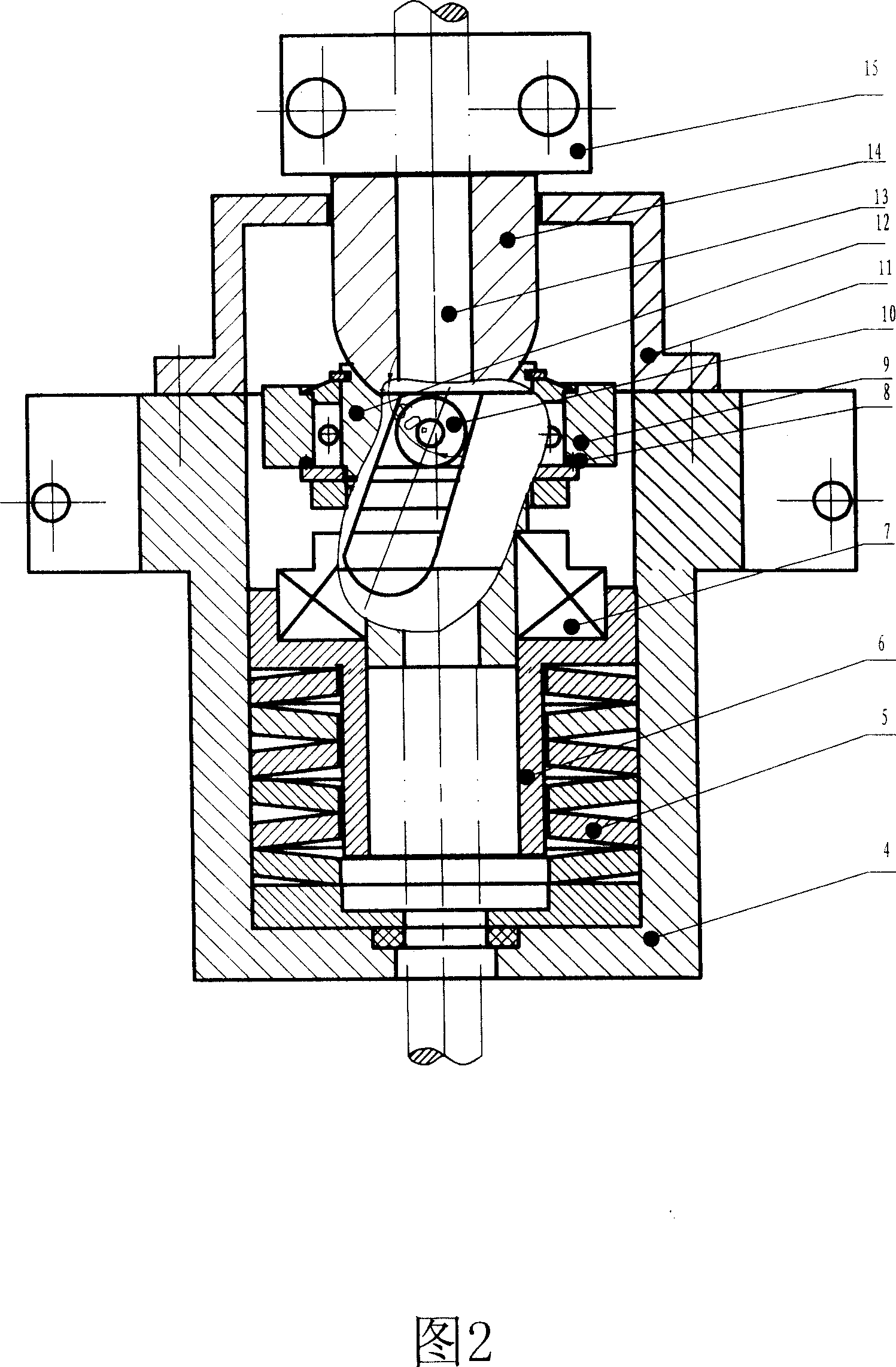

[0009] In the embodiment of Fig. 2, the casing 4, the load bearing body 6, the ratchet 9, the transmission member 10, the upper cover 11, the sucker rod seat 12, the universal joint 14, the polished rod clip 15 and other components are obtained by machining. The mutual positional relationship of each component is: first put several disc springs 5 into the housing 4 in a back-to-back or face-to-face combination, and then insert the load-bearing body 6 into the inner hole of the disc springs 5 . Then install the ratchet 9 assembly, put the sucker rod base 12 on the platform, install the inverted claw 8 and the ratchet 9 on its outer edge, fix the transmission part 10 on the outer edge of the ratchet, and then turn the assembly 180 °, insert the lower end into the inner hole of the axial bearing 7, then install the transmission part 10 in the chute of the housing 4, and then install the universal joint 14, the upper cover 11, and the polished rod clamp 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com