Novel automobile oil filler lock device

A fuel filler and lock device technology, which is applied in the field of new automotive fuel filler lock devices, can solve the problems of simple opening mechanism, simple design of lock tongue mechanism, lack of locking mechanism restrictions on the opening mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

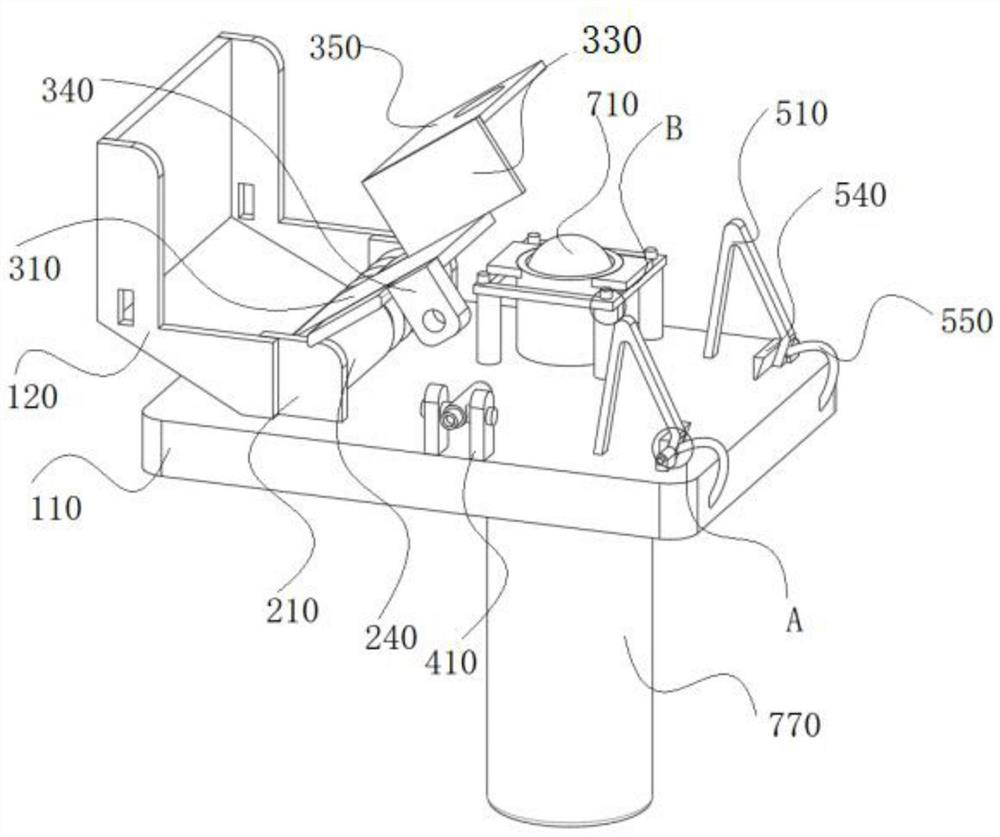

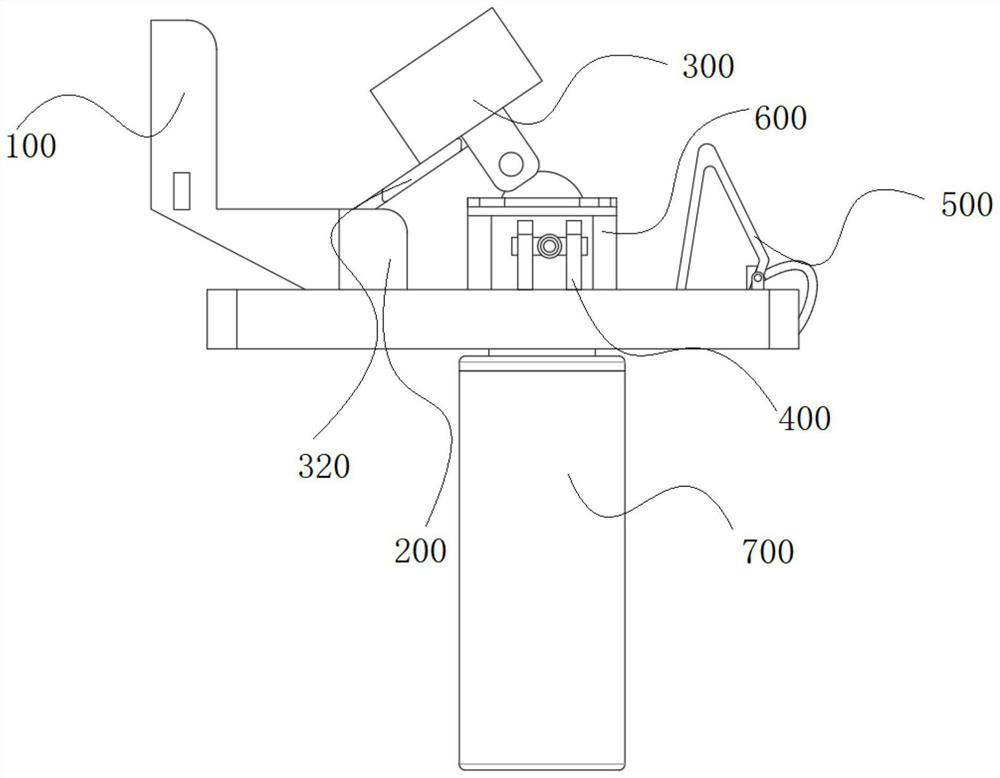

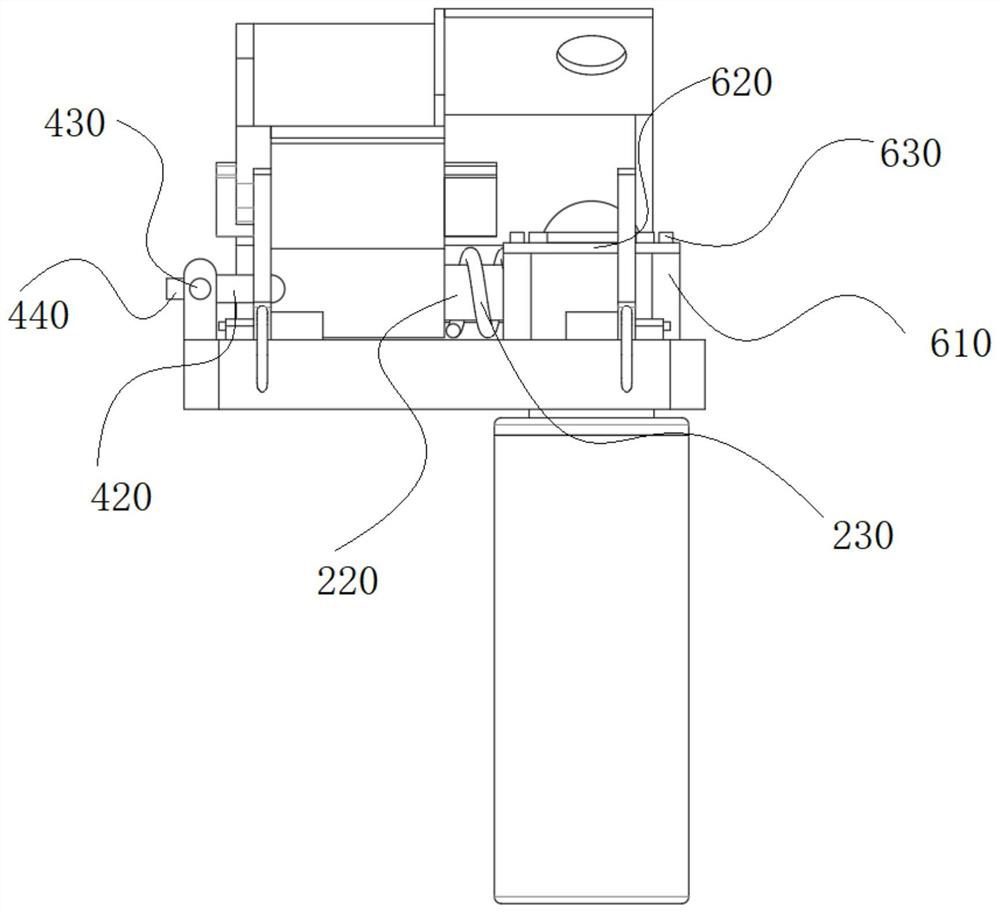

[0034] refer to figure 1—9. The present invention is a new type of automobile refueling port lock device, which includes a base 100, a rebound mechanism 200, an opening mechanism 300, a locking mechanism 400, a connecting mechanism 500, a fixing mechanism 600 and a deadbolt 700. The base 100 includes a bottom plate 110 The rebound mechanism 200 includes a connecting plate 210 and a rotating ring 240, the lower surfaces of the two connecting plates 210 are connected to the upper surface of the bottom plate 110, the opening mechanism 300 includes an opening rocker plate 310, and the first surface of the opening rocker plate 310 is connected to the rotating ring 240 The locking mechanism 400 includes a mounting bracket 410 and a first rotating column 430. One end of the two mounting brackets 410 is connected to the upper surface of the bottom plate 110, and the other ends of the two mounting brackets 410 are respectively connected to the two first rotation columns. The column 430...

Embodiment 2

[0043] The working principle of the present invention is as follows: the clamping plate 320 acts as a limit between the opening rocker plate 310 and the connecting plate 210, the rotating ring 240 rotates, and the perforated cover plate 350 is connected with the limiting column 630 along with the rotating ring 240, To achieve the function of locking and pressing the long column 710, after the connection between the locking plate 340 and the locking column 420 is completed, the position of the opening mechanism 300 is locked, and the movable cover 120 covers the perforated cover 350 in the open state. As a position limiter, the locking plate 340 rotates with the rotating ring 240 to a designated position and connects with the locking column 420, and the lock head 440 is connected with the external structure to complete the locking of the locking angle of the locking column 420, thereby completing the locking of the opening mechanism 300. The position is locked to ensure the lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com