Concave surface and convex surface detecting method and device of object with concave surface and convex surface being mirror reflection surfaces

A specular reflection and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high cost and unsuitable application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

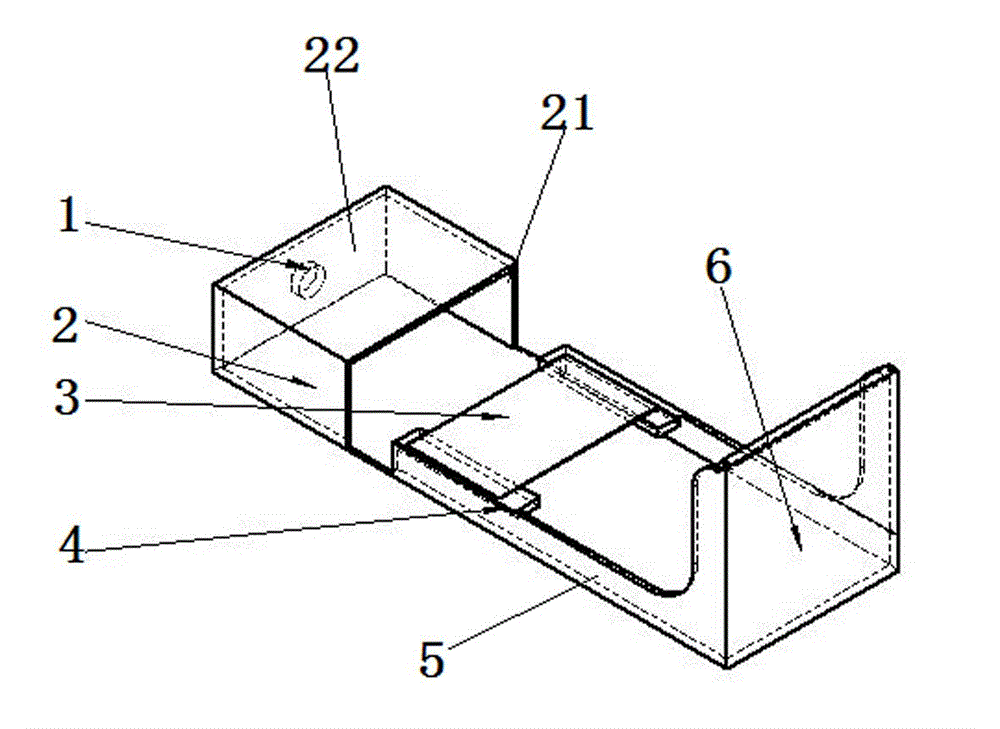

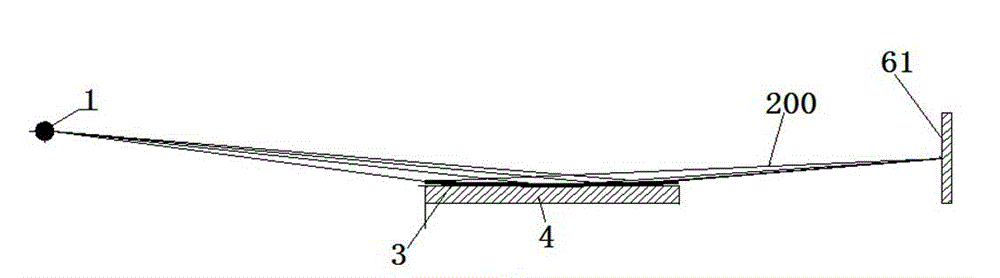

[0033] The object to be tested here is glass, one side of the glass is concave, and the other side is convex. The detection method in this embodiment specifically includes the following steps:

[0034](1) Use a light source that emits divergent light at the set irradiation position to irradiate the test surface of the glass to be tested at the set detection position. The surface receives the reflected light reflected from the surface to be measured to the projection surface,

[0035] (2) Observe the projection surface, if there is no image on the projection surface, the glass to be tested is unqualified; if there is an image on the projection surface, combine the image with the light source located at the set irradiation position to irradiate at the set detection position The preset standard part at the location is compared with the standard imaging formed by projecting on the projection surface at the set receiving position to determine whether the surface to be measured is c...

Embodiment 2

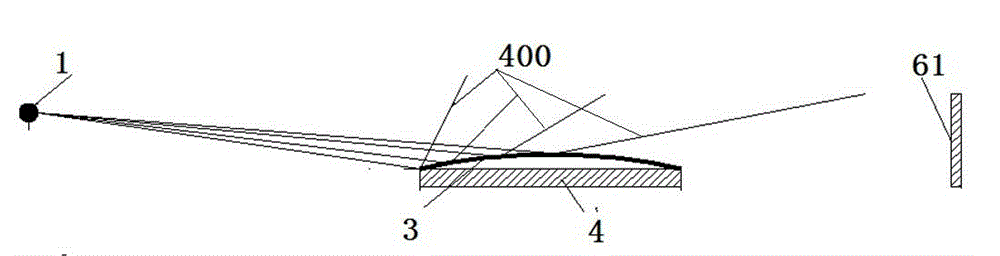

[0048] The detection method in this embodiment is different from the detection method in Embodiment 1 in that the detection method in this embodiment is only suitable for detecting mirror-reflective articles with both concave and convex surfaces, and specifically includes the following steps:

[0049] (1) The object to be tested has a first surface to be tested and a second surface to be tested with different concave and convex properties. The two surfaces to be tested are both specular reflective surfaces. The first surface to be measured of the object to be tested at the fixed detection position, and at the same time, the projection surface at the set position is used to receive the reflected light reflected from the first surface to be measured to the projection surface, and the projection surface is observed. If the projection surface If there is no image on the projection surface, the item to be tested is unqualified. If there is an image on the projection surface, record ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com