Intelligent single-cylinder dual-pressure forming equipment

A compression molding, intelligent technology, applied in the field of construction machinery, can solve the problems of cumbersome control system, easily damaged parts, complex structure, etc., and achieve the effects of good material compactness, low vibration and noise, and advanced principles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

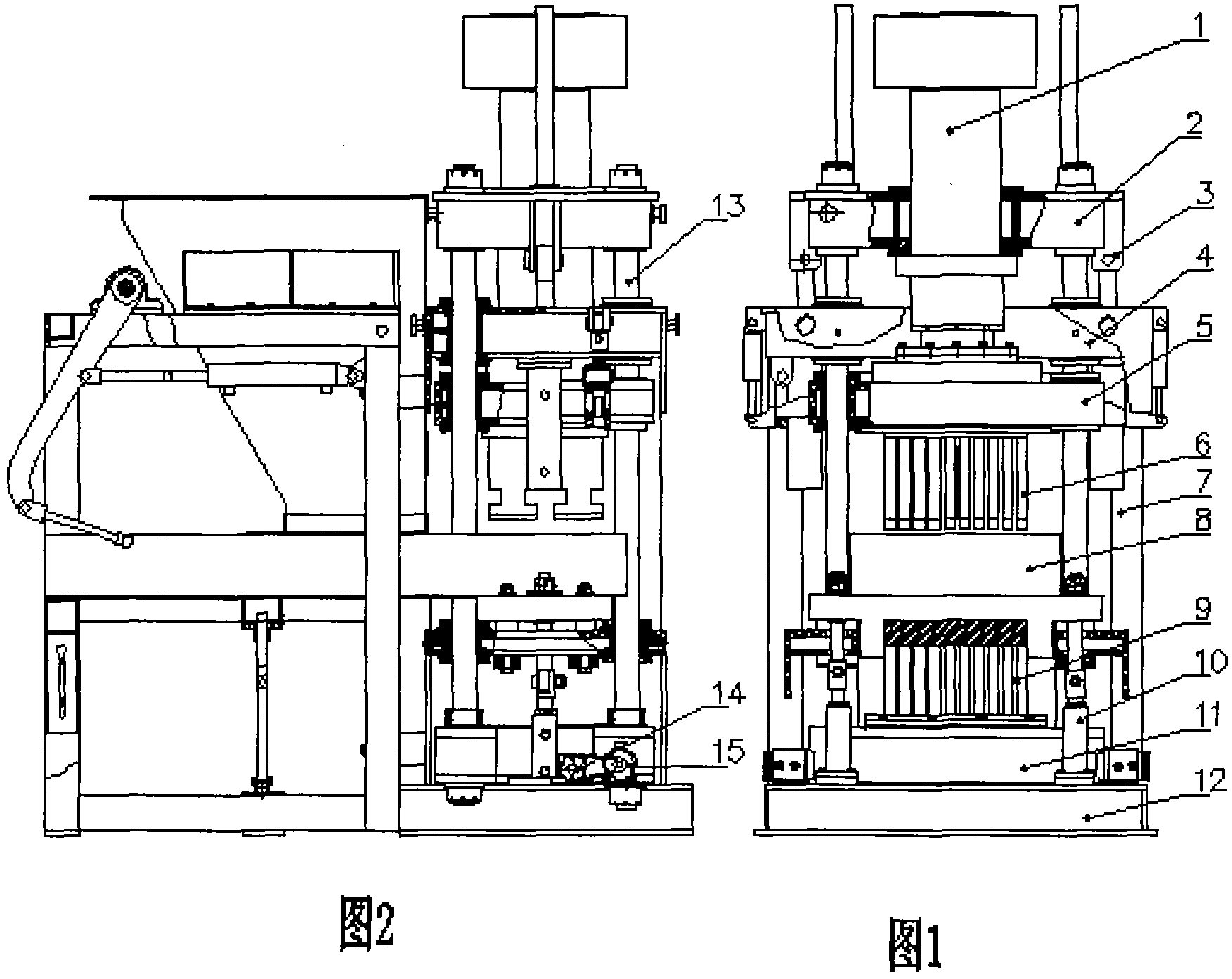

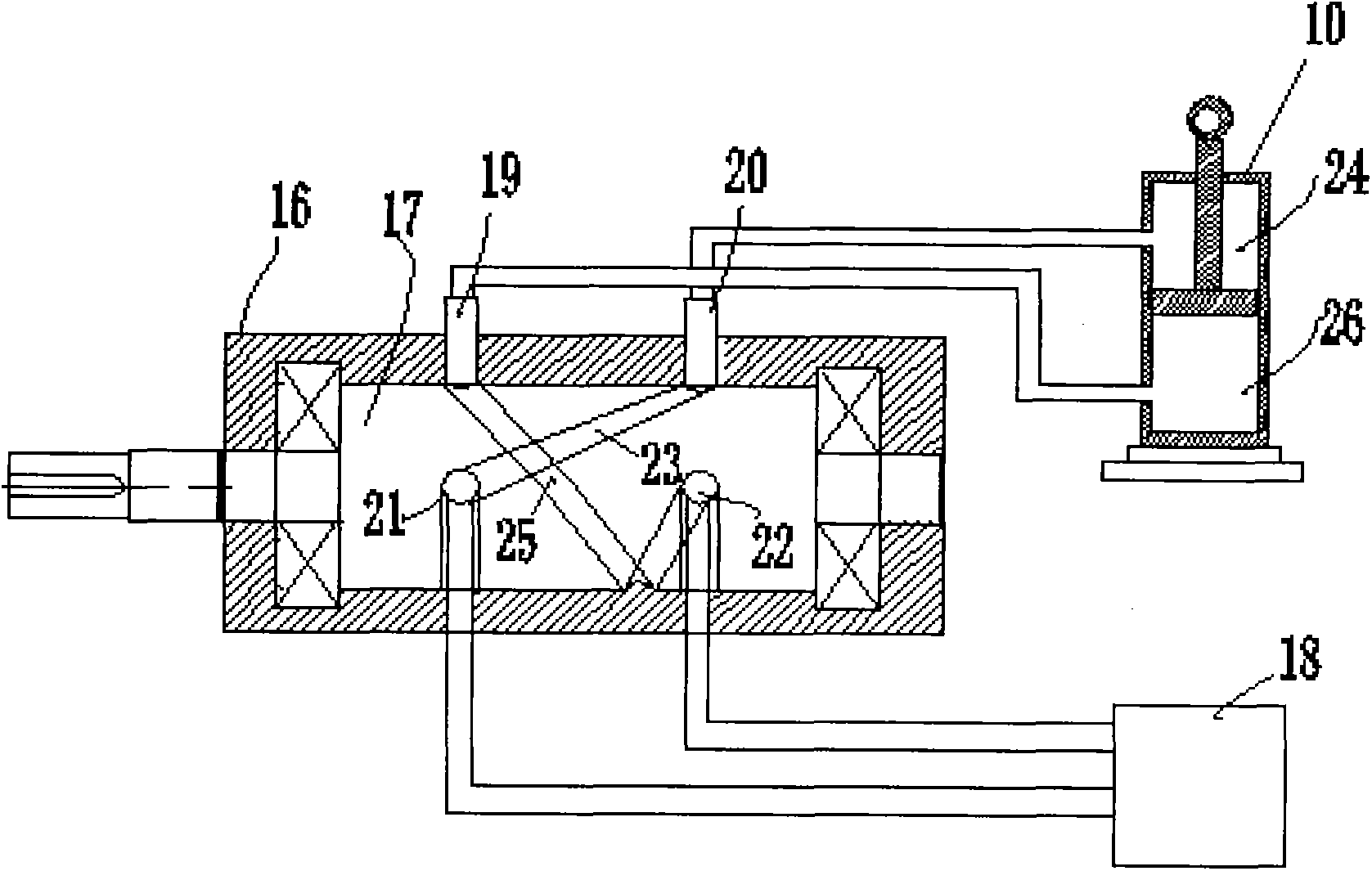

[0014] Such as figure 1 , 2 As shown, the intelligent single-cylinder double-pressure molding equipment mainly includes a frame, a column assembly, an oil cylinder assembly, a mold assembly, and a vibration assembly. The frame includes a top beam 4, a base 12, and a square column 7. The beam 4 is connected into a fixed frame by four square columns 7; the column assembly includes a column 13, an upper beam 2, a middle beam 5, and a lower beam 11, and the upper part of the column 13 is fixed to the upper beam 2, and the lower part of the column 13 is fixed to the lower beam 11 , the center beam 5 is guided by four uprights 13 to reciprocate up and down; the oil cylinder assembly includes a main oil cylinder 1, a vibration oil cylinder 10, and a return oil cylinder 3, the main oil cylinder 1 is connected with the center beam 5, and the vibration oil cylinder 10 is fixed on the base 12, The vibration oil cylinder 10 is connected with the shock wave device 14, and the shock wave d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com