Kitchen waste mechanical pretreatment system and pretreatment process thereof

A technology for kitchen waste and pretreatment, which is applied in the removal of solid waste and other directions, can solve the problems of low separation efficiency of organic matter, long pretreatment process chain and high impurity content, and achieves good odor control effect, energy consumption and maintenance cost. Low, high slurry purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

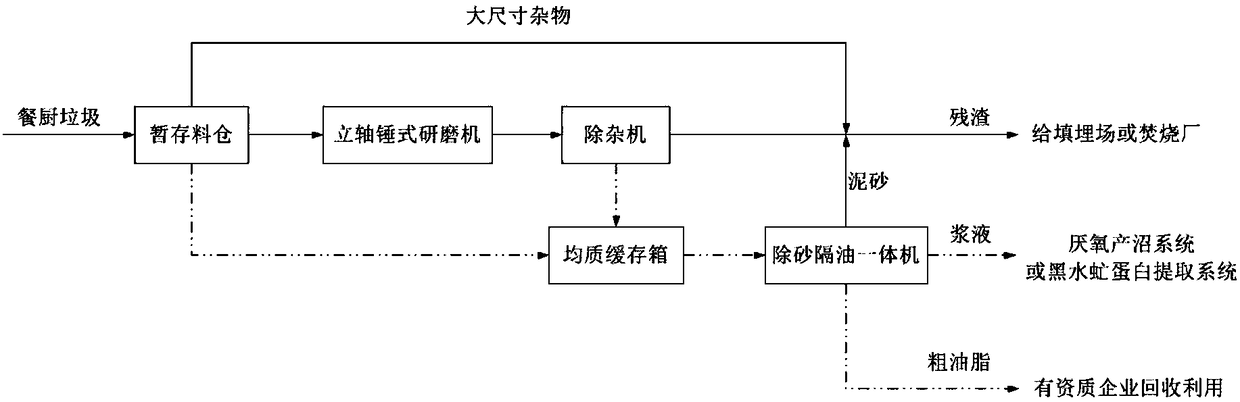

[0050] Such as figure 1 As shown, the food waste mechanical pretreatment system proposed in this embodiment includes: a temporary storage silo 1, a double shaftless screw conveyor 2, a vertical shaft hammer mill 3, a dust remover 4, and a homogeneous buffer box 5. And sand removal and oil separation machine 6.

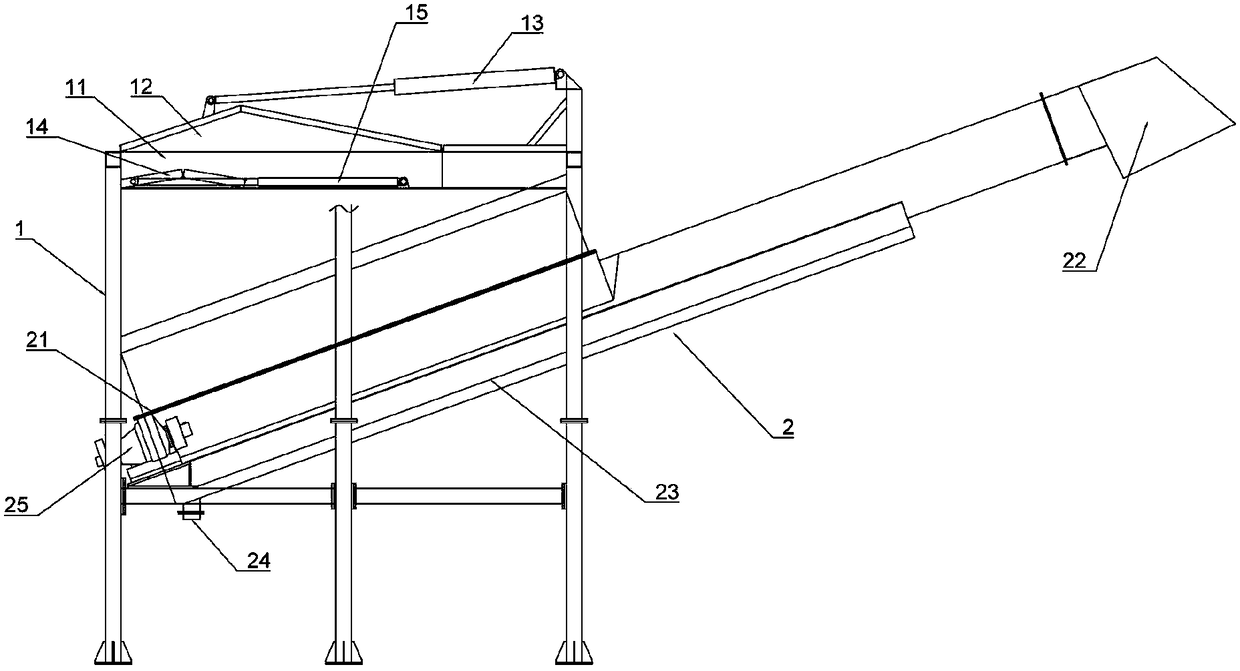

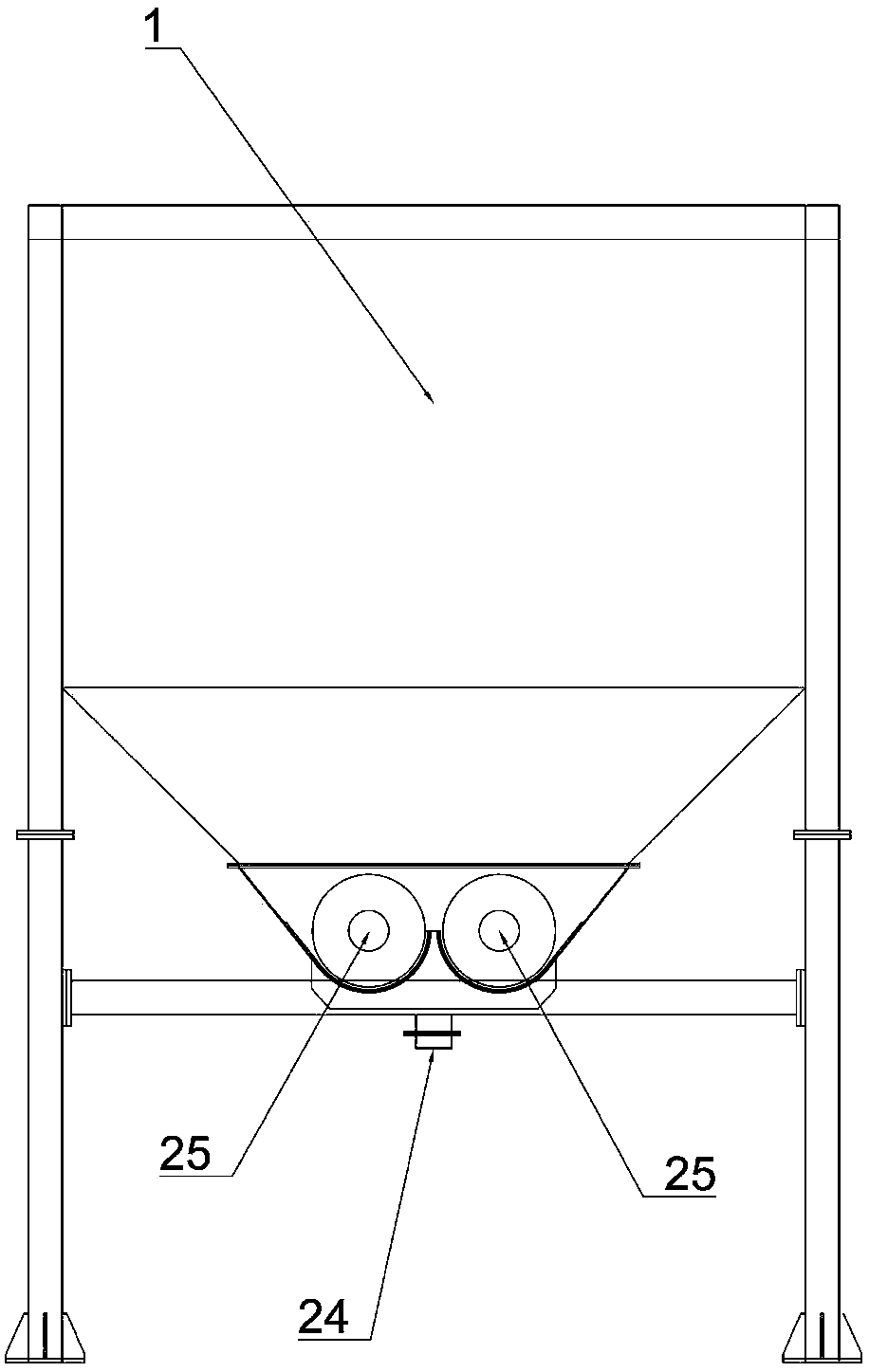

[0051] Such as figure 2 , image 3 with Figure 4 As shown, the temporary storage bin 1 is provided with a feed port 11 above the feed port 11 of the temporary storage bin 1 is covered with a reversible cover 12, the reversible cover 12 is in the normally open state, and the reversible cover 12 is driven by a large cylinder 13 to turn over. The feed inlet 11 of the temporary storage bin 1 is provided with a reversible grid 14 driven by a small cylinder 15, such as Figure 4 As shown, the grid size of the reversible grille 14 is 300×300mm, and the reversing state of the reversible grille 14 is as follows Figure 5 Shown.

[0052] Such as figure 2 , image 3 with Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com