Integrated microstructure backlight system

A technology of backlight system and micro optics, applied in the field of backlight system, can solve problems such as the inability to meet the integration requirements of backlight modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

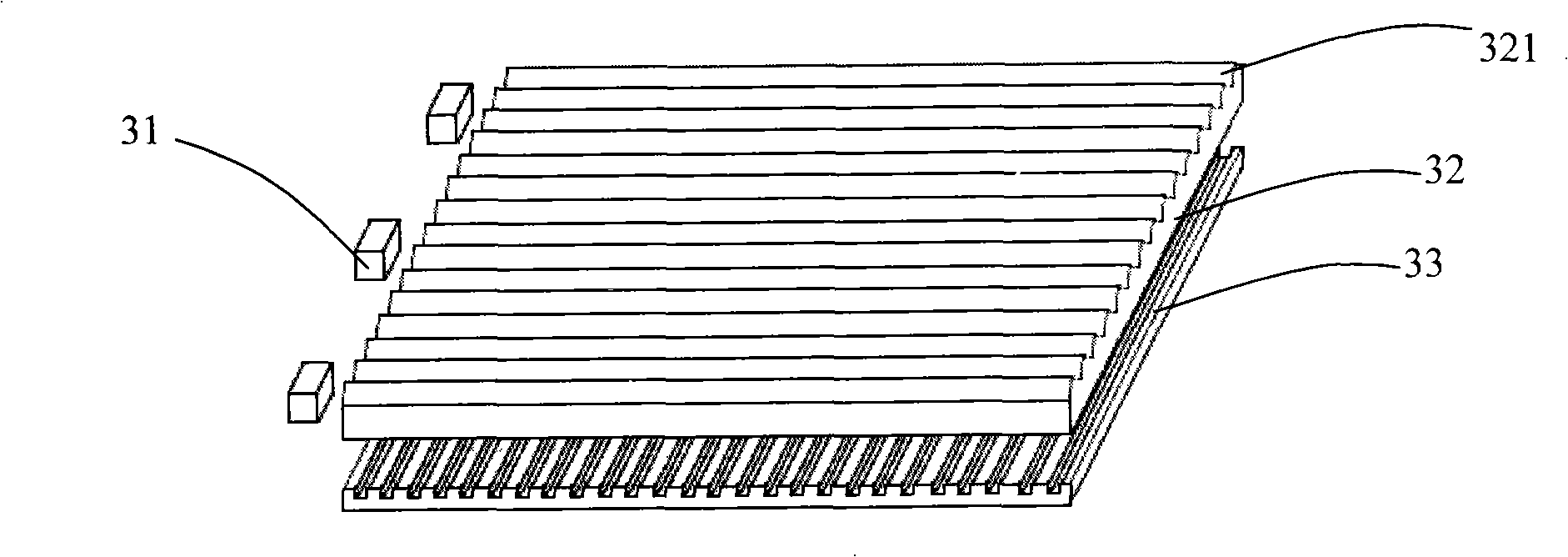

[0028] Such as image 3 as shown, image 3 It is a structural schematic diagram of an embodiment of the integrated microstructure backlight system of the present invention. The backlight system of this embodiment includes: a light source 31 , a light guide plate 32 and a reflection sheet 33 . Wherein, the light guide plate 32 includes a light incident surface for receiving light emitted by the light source 31, a light exit surface for emitting light, and a bottom surface opposite to the light exit surface, and a micro-optical light concentrating structure is arranged on the light exit surface of the light guide plate 32. The micro-optical light-concentrating structure can be a prism, a cone, a pyramid, a truncated cone, a truncated prism, a pyramid with a concave top area, a cone with a concave top area, a prism with a concave top area, or a truncated cone with a concave top area, such as image 3 The microprism structure 321 shown, Figure 7 is a pyramidal structure with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com