Metal base monolithic catalyst for preparing low carbon hydrocarbons by using methane through oxidative coupling and preparation method thereof

A monolithic catalyst and oxidative coupling technology, applied in the field of catalysis, to achieve the effects of good thermal conductivity, low thermal resistance, and reduced bed lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

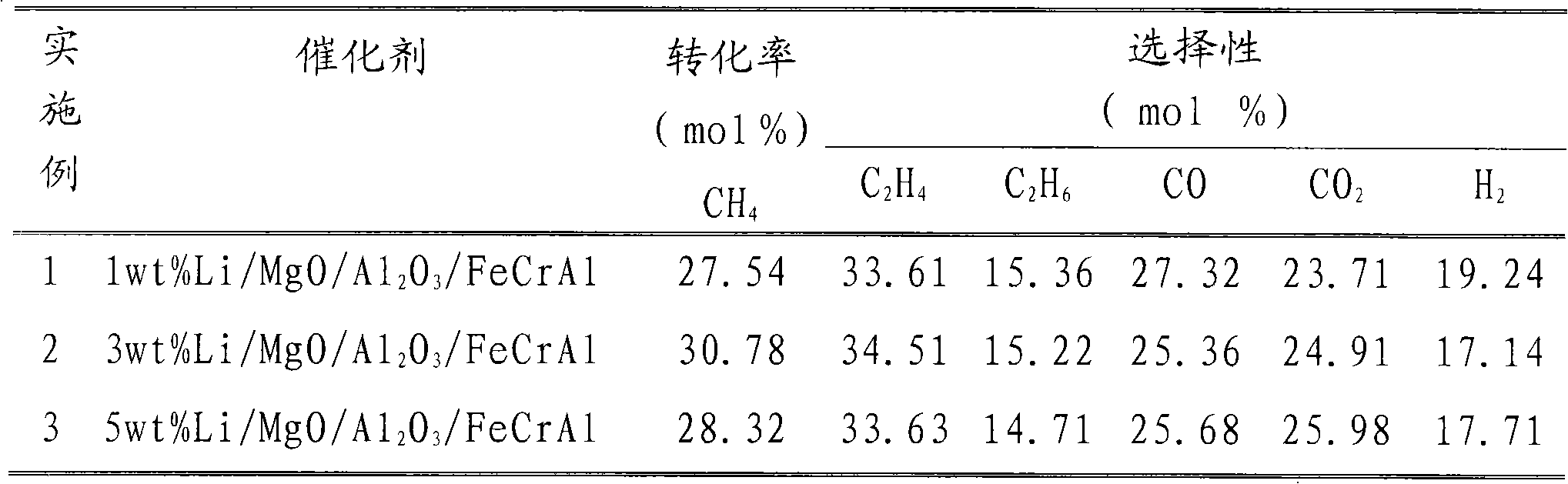

[0024] The catalyst of the present invention is used for the reaction of oxidative coupling of methane to produce ethylene, which is carried out on a micro-fixed-bed reaction device at normal pressure, and the catalyst bed is composed of {catalytically active components} / Al with a height of 10-15 cm 2 o 3 / FeCrAl metal-based monolithic catalyst composition. The volume ratio of methane and oxygen in the reaction raw material gas is 3: 1, and the gas space velocity (that is, every gram of catalyst (Al except FeCrAl alloy carrier) 2 o 3 The sum of the mass of dry sol and {catalytic active component})) is 42000h -1 , the reaction temperature is 700-850°C, and after 30 minutes of stability at the reaction temperature, the reactants and products are analyzed online with a gas chromatograph, so as to obtain the conversion rate of methane and the ratio of ethylene, ethane, CO and H 2 selectivity.

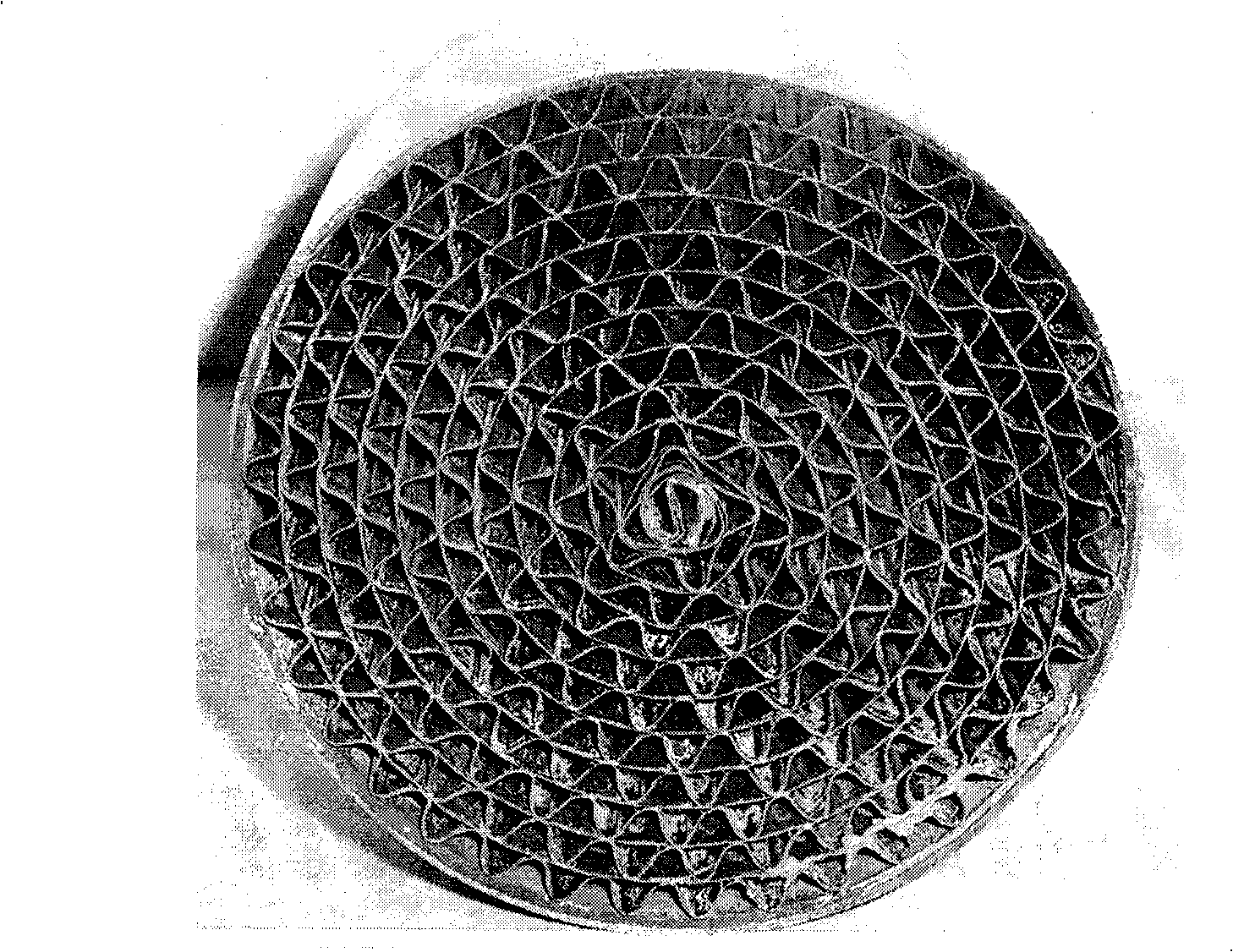

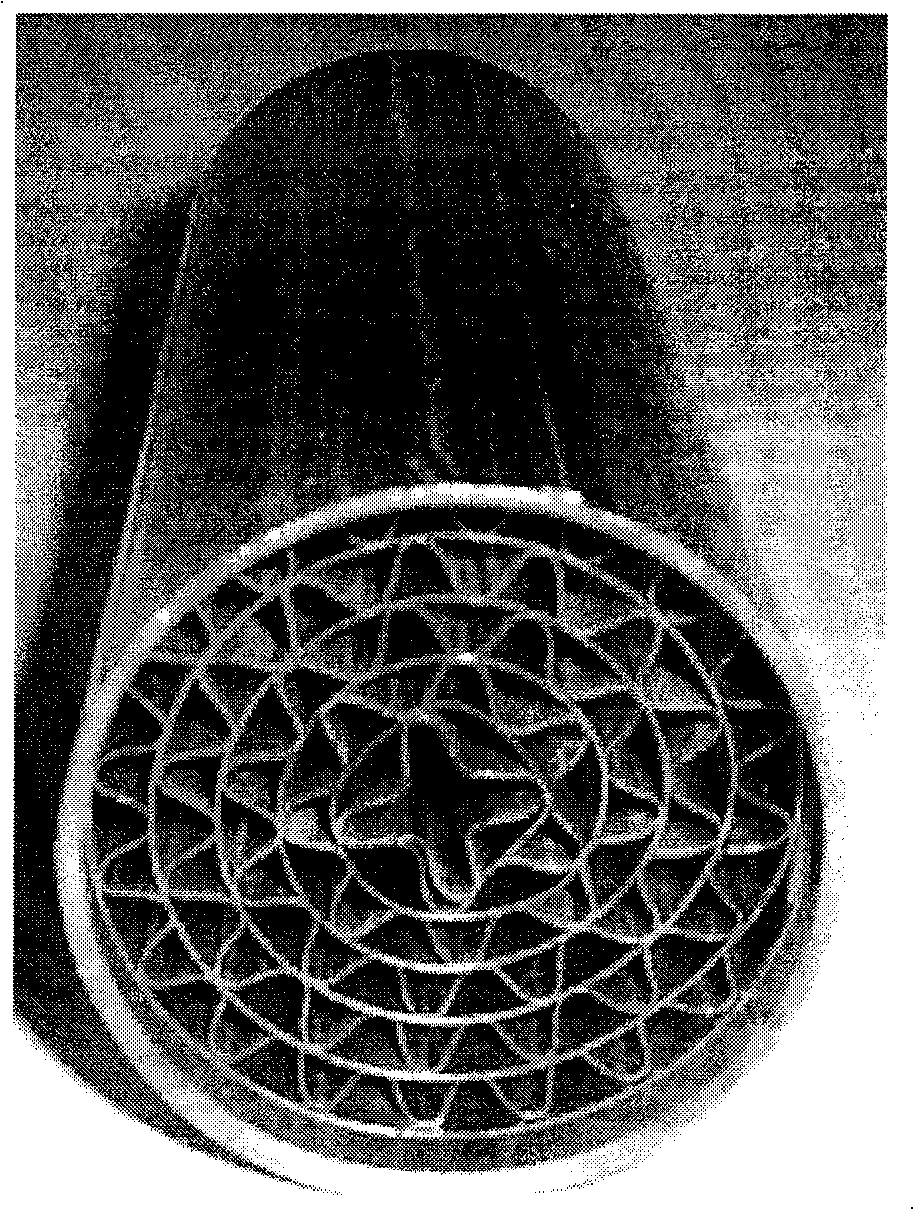

[0025] The structure of the catalyst of the present invention when used is a roll s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com