Outboard on-orbit operated ground test method of spacecrafts

A technology for ground testing and spacecraft, applied in space navigation equipment, simulation devices of space navigation conditions, transportation and packaging, etc., to achieve the effects of avoiding discomfort, convenient state setting, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

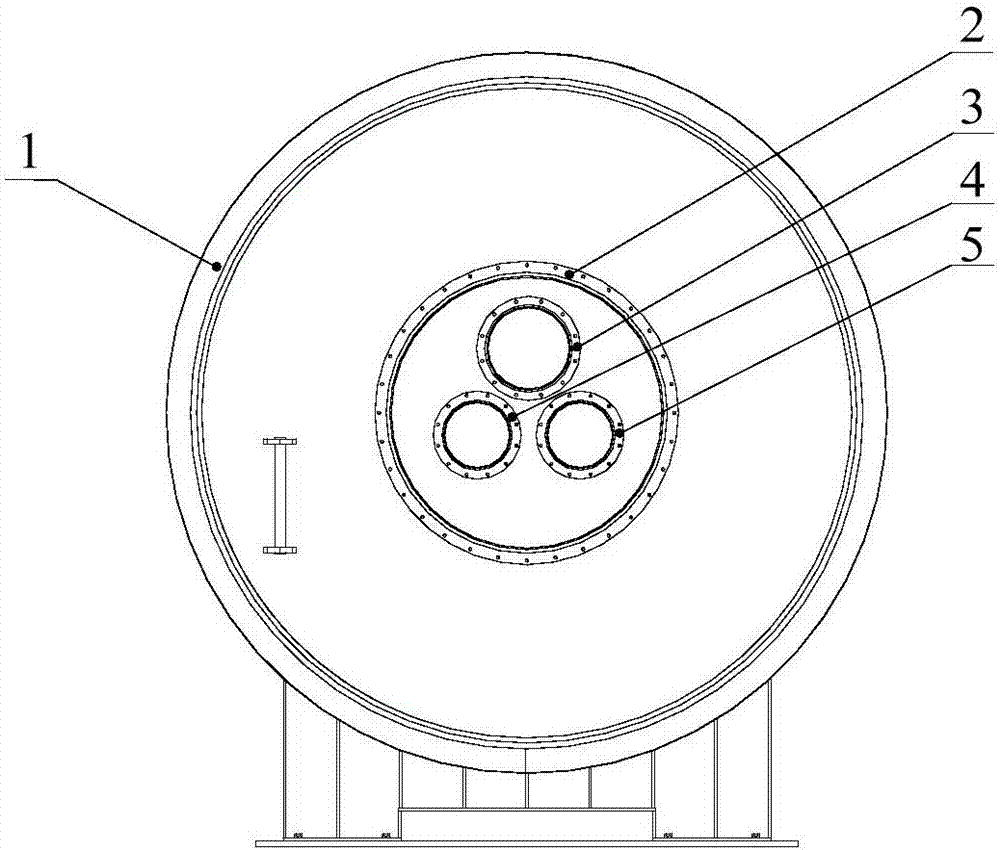

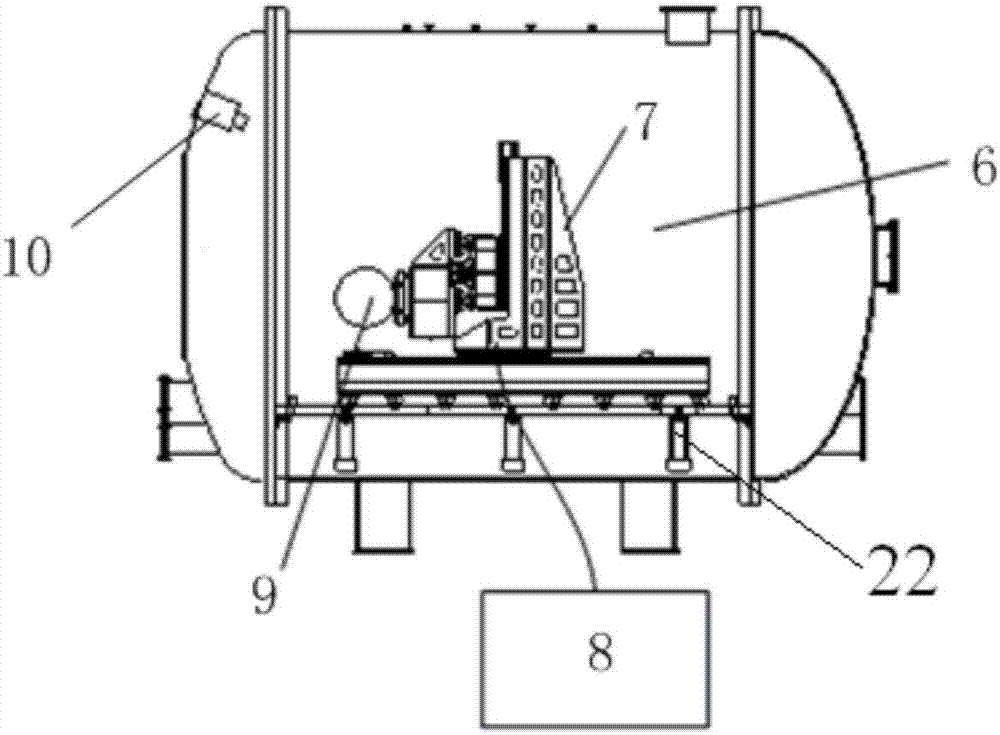

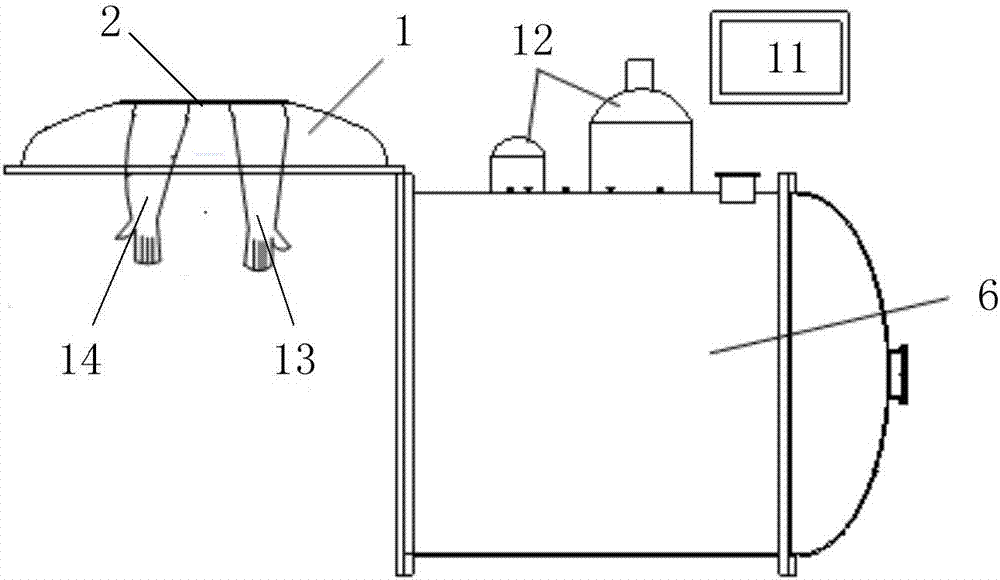

[0051] Such as figure 1 , figure 2 , image 3As shown, the spacecraft extravehicular on-orbit operation ground test system includes a servomechanism 7, a servomechanism console 8, a vacuum tank 6, an observation window 3, extravehicular space suit gloves 13, 14 and a bracket guide rail 22; Observation windows 3 and extravehicular space suit gloves 13, 14 are provided, and the extravehicular space suit gloves 13, 14 extend into the inside of the vacuum tank 6 and are sealed and connected with the vacuum tank 6; the bracket guide rail 22 and the servo mechanism 7 All are located inside the vacuum tank 6, the bracket guide rail 22 is fixed on the bottom of the vacuum tank 6, the servo mechanism 7 is installed on the bracket guide rail 22; the test piece 9 is installed on the servo mechanism 7, and has four movements under the control of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com