Forming machine for boxes with covers and special mold

A technology for forming molds and forming machines, which is used in envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of poor coordination effect, low comprehensive accommodation capacity, affecting the accommodation capacity of lunch boxes, etc. , the effect of flow reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

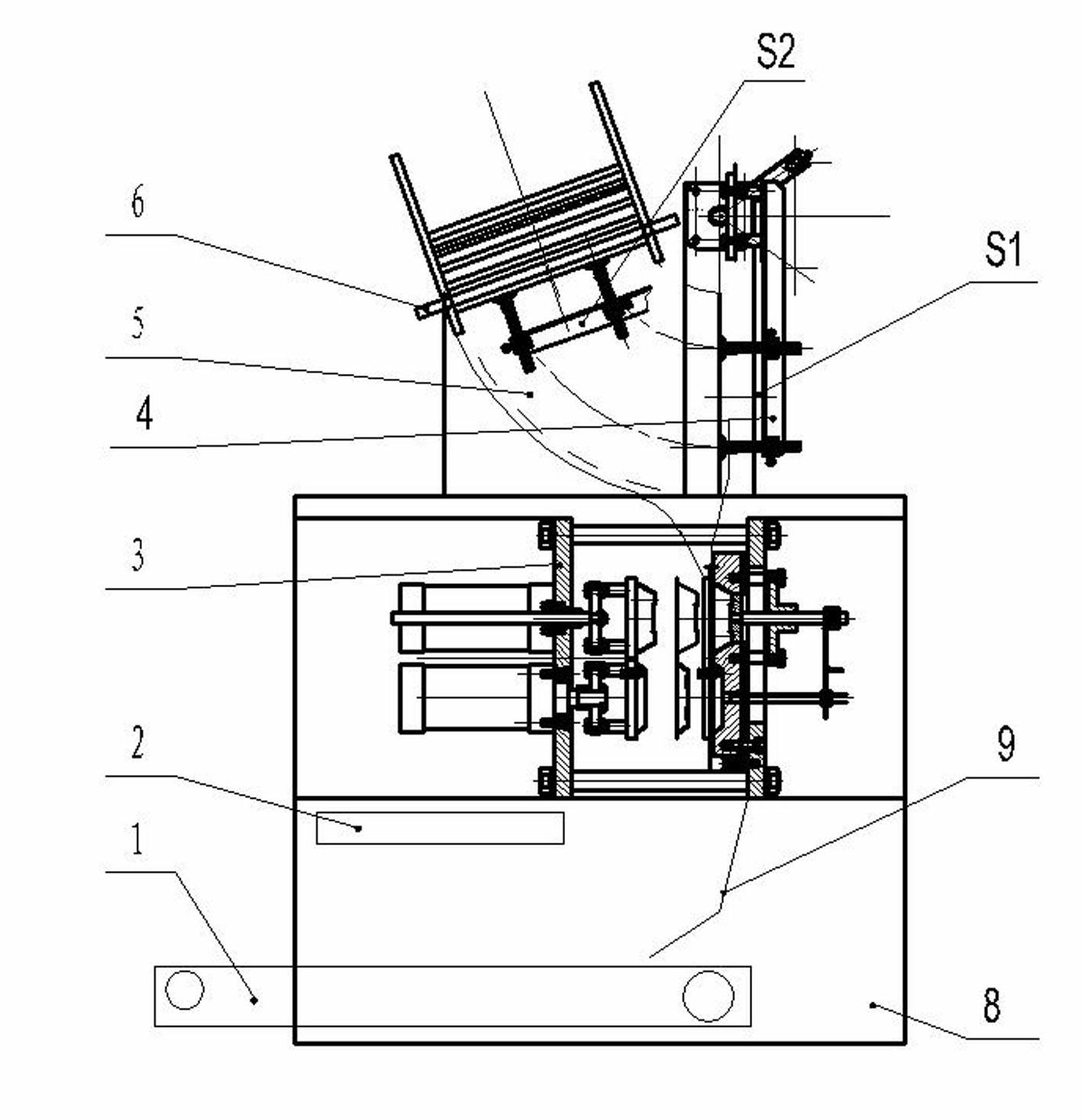

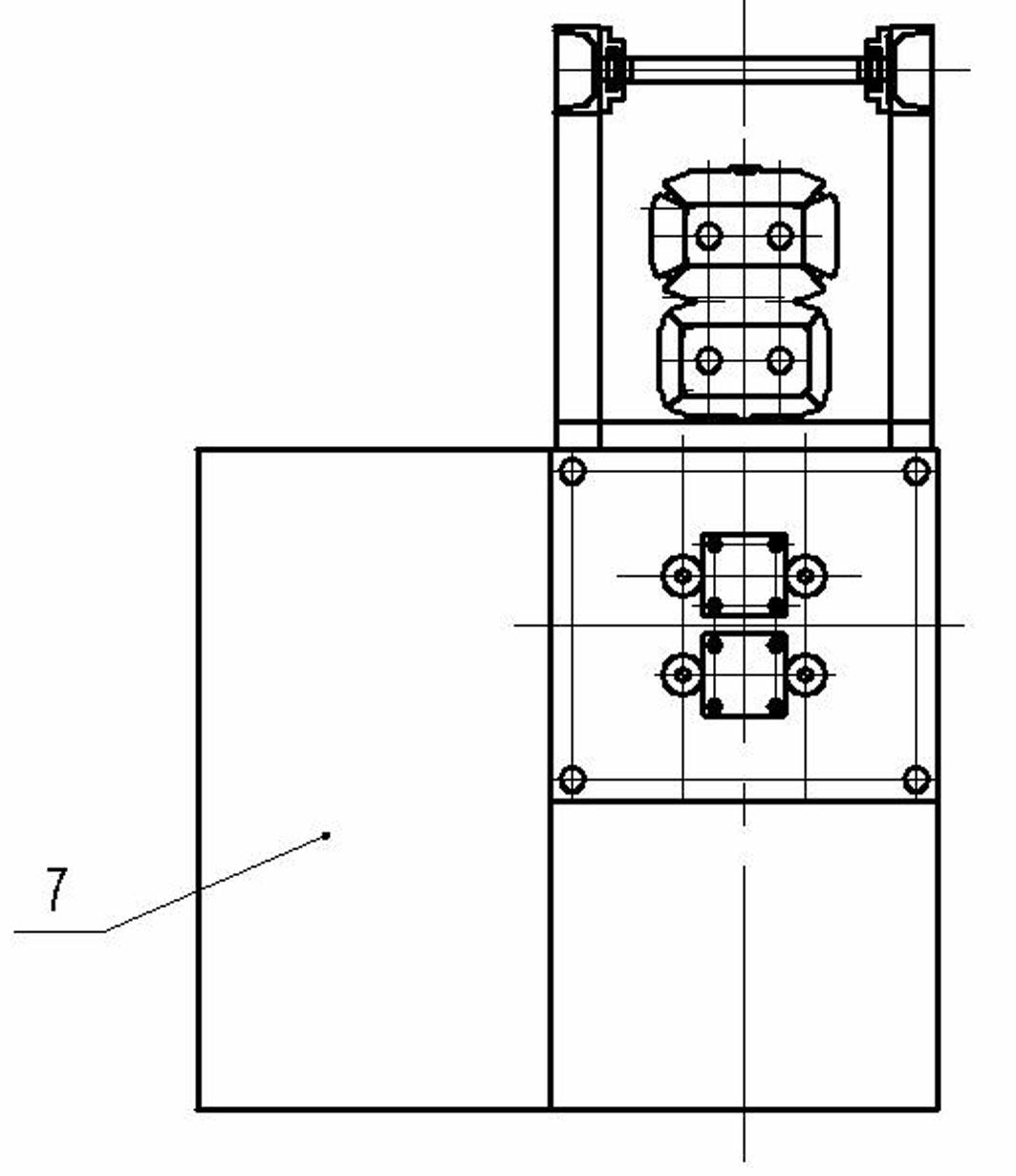

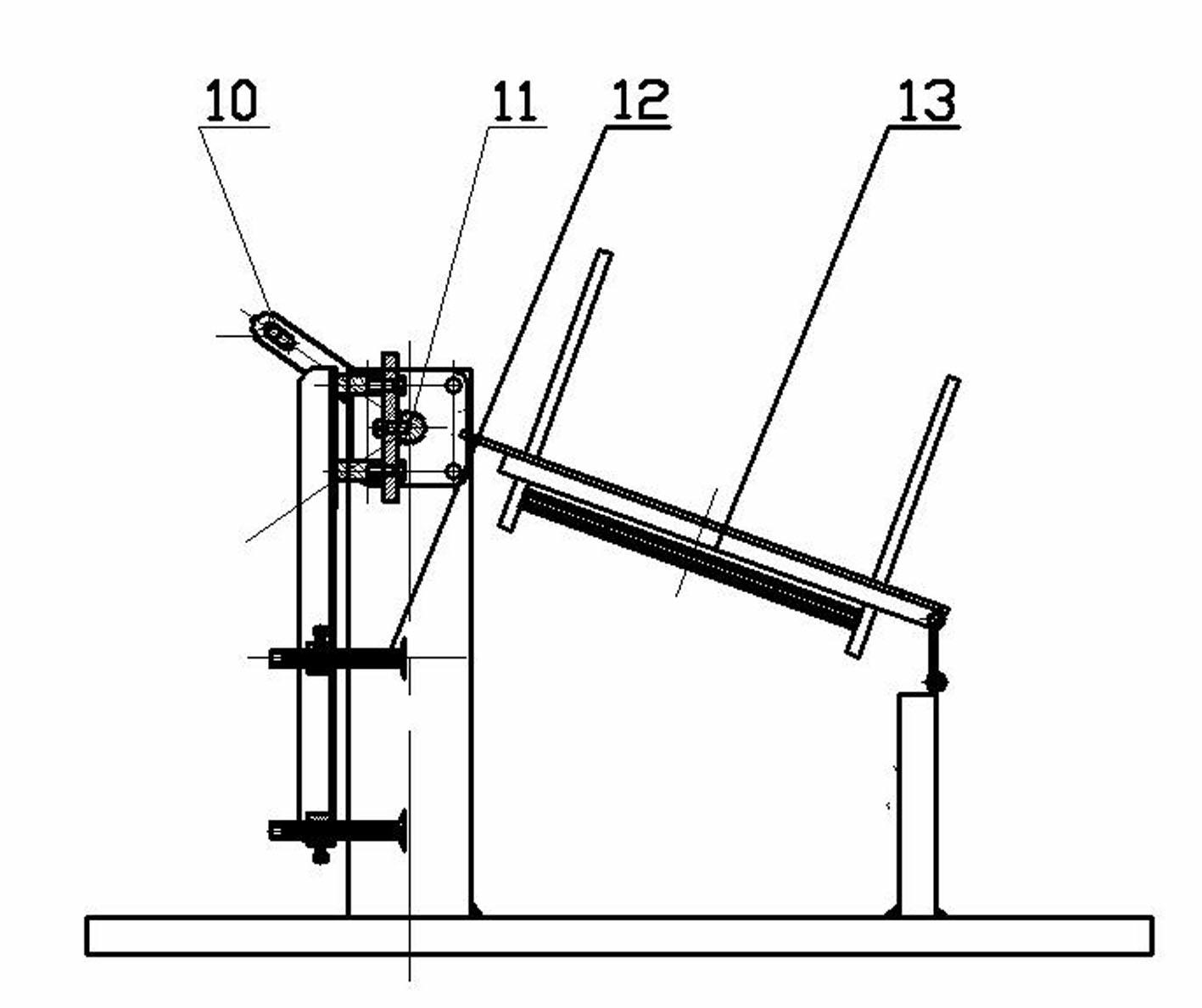

[0036] Instructions attached Figures 1 to 5 It is an example of the structure of the forming mold and forming machine, but it does not constitute a limitation on the claims. The simplified drawing method is used in the figure, which is only used for clear expression and does not represent the processing structure of the real product.

[0037] The term names used in the description of the examples may contain specific structures or characteristics, but are only used to express the technical conditions of the examples, and shall not limit the technical solutions required by the present invention.

[0038] Based on a better example, the attached figure 1 and 5 It clearly shows the structure and assembly structure of the molding die. The stamping direction in the figure is horizontal. It is obvious that when the stamping direction is vertical, it will not have any impact on the molding itself. Therefore, the traditional vertical direction selection Also applicable to this progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com