Three-station edge rolling mold for aluminum-based cam shaft sleeve

A camshaft, three-station technology, applied in the field of machinery, can solve the problems of reduced product processing quality and production efficiency, and achieve the effect of avoiding secondary positioning, improving production efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

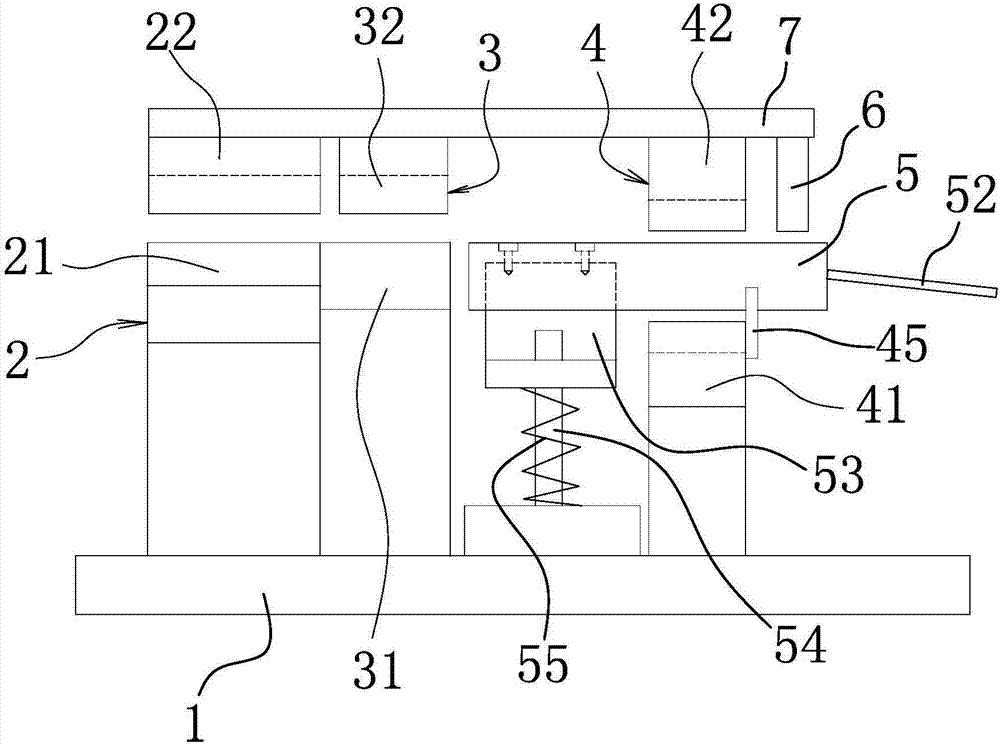

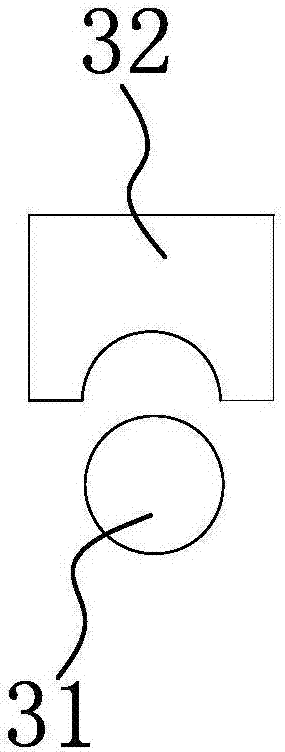

[0034] Such as Figure 1-6 and Figure 8 As shown, the aluminum-based camshaft sleeve three-station rolling mold includes a bottom plate 1, a top plate 7 is arranged on the bottom plate 1, and a primary pre-bending module 2 and a secondary pre-bending module are arranged in sequence on the bottom plate 1. 3 and rolling die set 4.

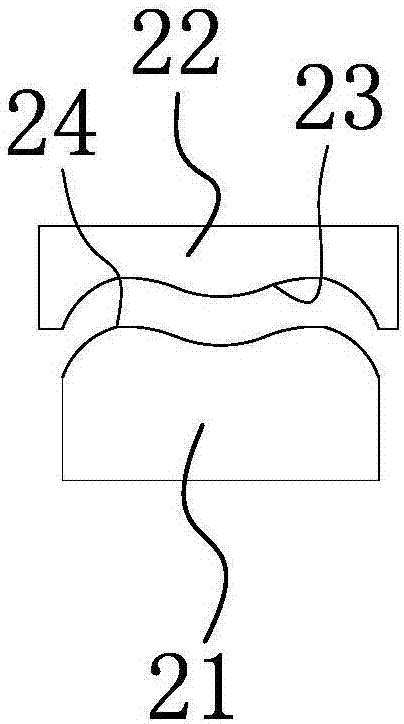

[0035] Specifically, the primary pre-bending die set 2 includes a primary pre-bending punch 21 and a primary pre-bending die 22 located above the primary pre-bending punch 21 , and the primary pre-bending punch 21 and the primary pre-bending die 22 match each other.

[0036] The primary pre-bending punch 21 is fixed on the base plate 1 , and the primary pre-bending die 22 is fixed on the lower surface of the top plate 7 .

[0037] The upper surface of the primary pre-bending punch 21 has an m-forming convex surface 24, and the lower surface of the primary pre-bending die 22 has an m-forming concave surface 23, and the m-forming convex surface 24 a...

Embodiment 2

[0064] The structure and principle of this embodiment are basically the same as those of Embodiment 1, so they will not be repeated here. The difference lies in:

[0065] Such as Figure 7 As shown, the upper surface of the primary pre-bending punch 21 has an inverted U-shaped forming convex surface, and the lower surface of the primary pre-bending die 22 has an inverted U-shaped forming concave surface, and the forming convex surface and the forming concave surface match each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com