Machine box outer case connection structure of rolling drum washing machine

A technology for a drum washing machine and a case shell, which is applied to other washing machines, washing devices, textiles and paper making, etc., can solve problems such as laborious work, and achieve the effects of avoiding position adjustment, simplifying connection and easy connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given in conjunction with the accompanying drawings:

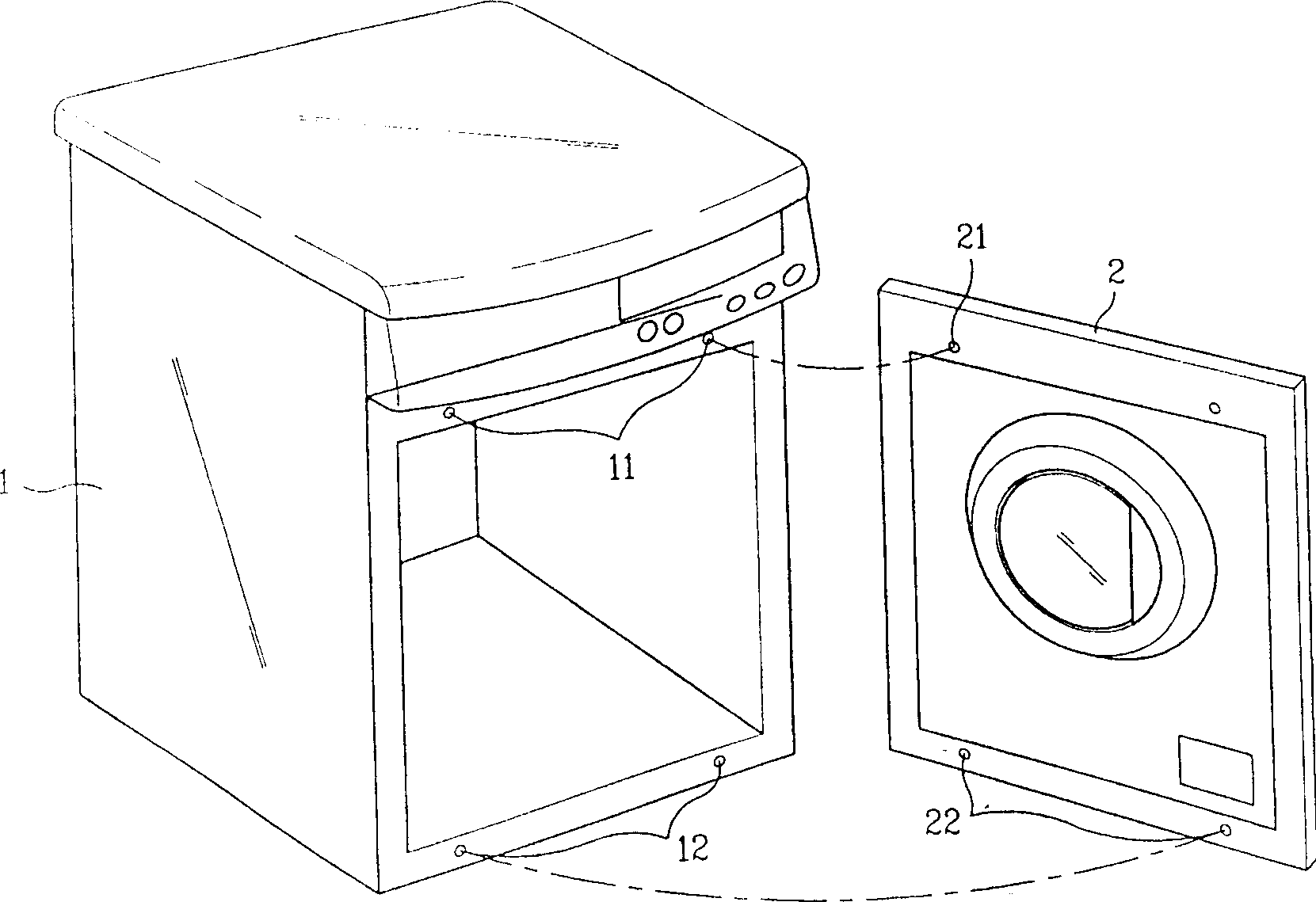

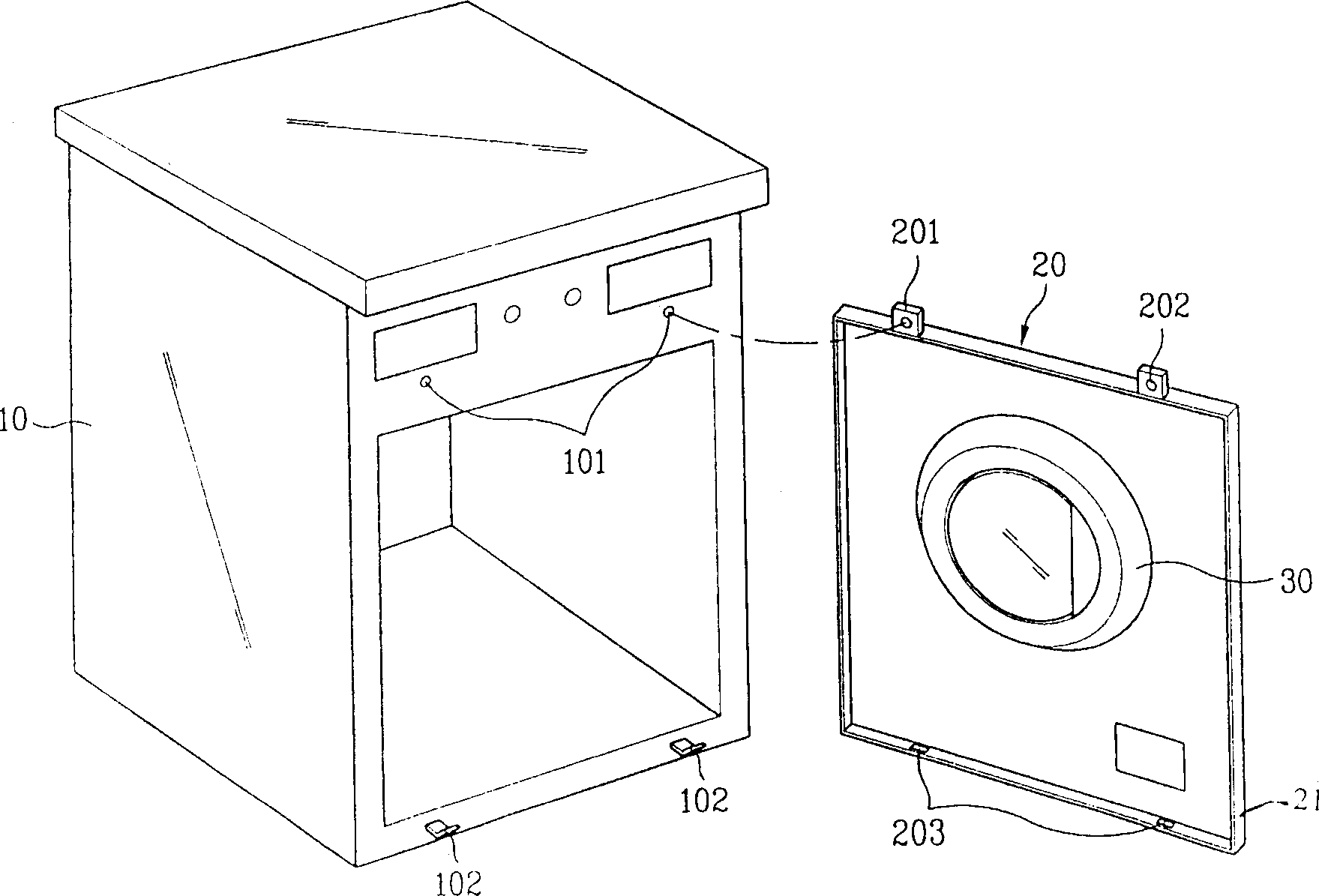

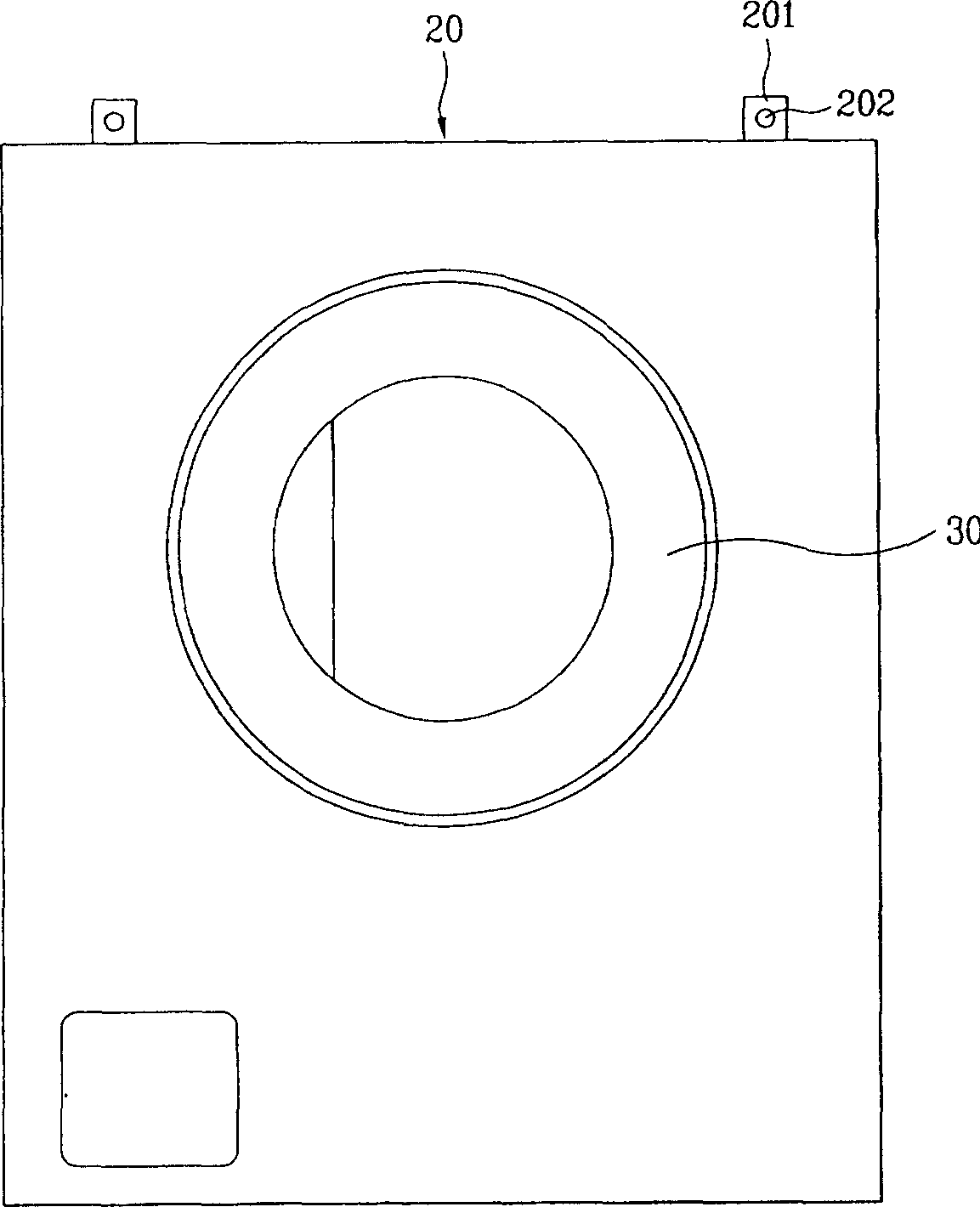

[0024] figure 2 with image 3 Shown is the structure of the cabinet of drum washing machine among the present invention, and the cabinet of drum washing machine is mainly by the casing (10) that the front is opened and is connected with the cabinet shell ( 20) Composition.

[0025] Two upper connection holes (101) are formed on both sides of the upper part of the box body (10), and two fixing plates (102) extending forward are arranged on both sides of the lower end, and the ends of the fixing plates (102) are slightly bent upwards with.

[0026] Two connecting pieces (201) are formed on the upper end of the chassis shell (20), and connecting holes (202) corresponding to the upper connecting holes (101) of the casing are also provided on the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com